In today’s competitive manufacturing landscape, efficiency and precision have become paramount for businesses aiming to maintain a competitive edge. One crucial component that significantly impacts production quality and speed is the Industrial Coating Machine. These advanced machines play a vital role in various manufacturing processes, applying protective and aesthetic coatings to products with unparalleled accuracy. By investing in an Industrial Coating Machine, manufacturers can streamline their operations, reduce labor costs, and ensure a consistent finish across all items produced.

The benefits of integrating an Industrial Coating Machine extend beyond mere efficiency. These machines can enhance the durability of products by applying coatings that provide resistance to corrosion, abrasion, and various environmental factors. Furthermore, modern Industrial Coating Machines come equipped with innovative technologies that allow for customization and flexibility in coating applications. This advancement not only meets the specific needs of diverse industries but also promotes sustainability by reducing material waste and improving overall production quality.

As manufacturers strive for innovation and excellence, incorporating an Industrial Coating Machine into their processes emerges as a strategic solution. The ability to achieve higher consistency and lower production costs positions businesses to meet the evolving demands of the market while ensuring their products uphold the highest standards of quality. Ultimately, the use of an Industrial Coating Machine is a forward-thinking approach that can redefine operational efficiency and product excellence in the manufacturing sector.

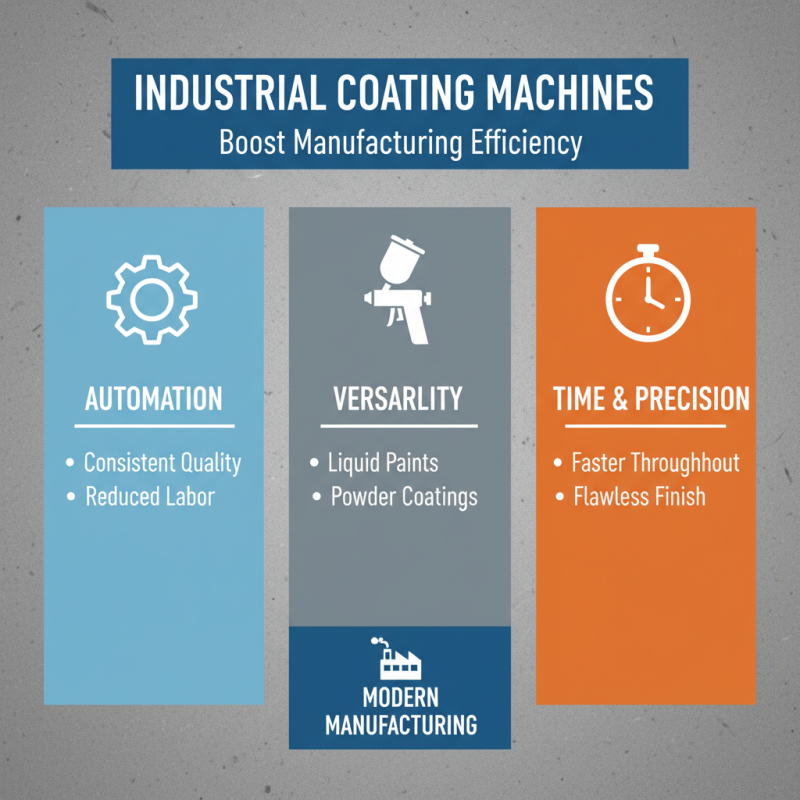

Industrial coating machines play a vital role in enhancing manufacturing efficiency by automating the coating process, ensuring consistent quality, and saving time. These machines are designed to handle various types of coatings, from liquid paints to powders, making them versatile tools in modern manufacturing settings. By employing an industrial coating machine, manufacturers can achieve a higher level of precision in the application of coatings, which is crucial for products that require a specific finish or protective layer.

Tips: When selecting an industrial coating machine, consider the specific needs of your production line. Assess the types of coatings you will be using and ensure that the machine can accommodate those materials. Additionally, investing in a machine with advanced features such as automated settings can significantly reduce the risk of human error and improve overall output.

Another important aspect of industrial coating machines is their ability to reduce waste and enhance resource efficiency. By controlling the amount of coating material used and providing a uniform application, these machines minimize overspray and excess usage of coatings, which can lead to cost savings. Implementing regular maintenance checks on your coating machines can further enhance their efficiency and lifespan, ensuring that they continue to perform at optimal levels.

Industrial coating machines play a pivotal role in various manufacturing processes by providing surface protection and enhancing aesthetic qualities. There are several types of industrial coating machines, each designed for specific applications. For instance, spray coating machines are widely used in automotive and furniture industries for uniform coverage. These machines use high-pressure systems to atomize the coating material, allowing for an even application that minimizes waste. Additionally, they can accommodate a variety of coating types, including paints, varnishes, and sealants, making them versatile for different manufacturing needs.

Another notable type is the electrostatic coating machine, which employs an electrostatic charge to attract coating particles to the substrate. This technique is particularly effective for coatings on metal parts, as it reduces overspray and improves transfer efficiency. Moreover, powder coating machines apply dry paint powder that melts upon heating, creating a durable and attractive finish suitable for outdoor applications. Each of these machines is tailored to improve efficiency and enhance the final product's quality, underscoring their importance in modern manufacturing settings.

| Machine Type | Application | Benefits | Material Compatibility |

|---|---|---|---|

| Electrostatic Spray Gun | Automotive and Aerospace Parts Coating | High transfer efficiency, reduced waste | Metal, Plastic |

| HVLP Spray System | Furniture and Home Appliances Coating | Fine finish, less overspray | Wood, Metal |

| Powder Coating Machine | Metal Parts and Frame Coating | Durable finish, environmentally friendly | Metal |

| Dip Coating Equipment | Electronic Components Coating | Uniform coating, ideal for complex shapes | Plastic, Metal |

| Liquid Coating System | Industrial Machinery Coating | Versatile application, smooth finish | Various Materials |

Implementing industrial coating machines in manufacturing processes can yield substantial benefits that enhance both efficiency and product quality. One of the key advantages is the improved durability of coated products. By providing protective layers, these machines ensure that items are resistant to wear, corrosion, and harsh environmental conditions. This not only extends the lifespan of manufactured goods but also reduces the costs associated with repairs and replacements over time.

Additionally, industrial coating machines streamline production workflows. They enable consistent application of coatings, minimizing variations that can occur with manual processes. This leads to higher quality outputs and reduced waste, as excess material is less likely to be used. Furthermore, the automation of the coating process allows manufacturers to increase their output rates, ultimately boosting overall productivity.

Tips: To maximize the effectiveness of industrial coating machines, regularly maintain and calibrate the equipment to ensure consistent performance. Additionally, consider analyzing the specific coating needs of your products to select optimal materials and processes tailored to your manufacturing goals. Emphasizing employee training on the operation of these machines can also further enhance productivity and safety in the workplace.

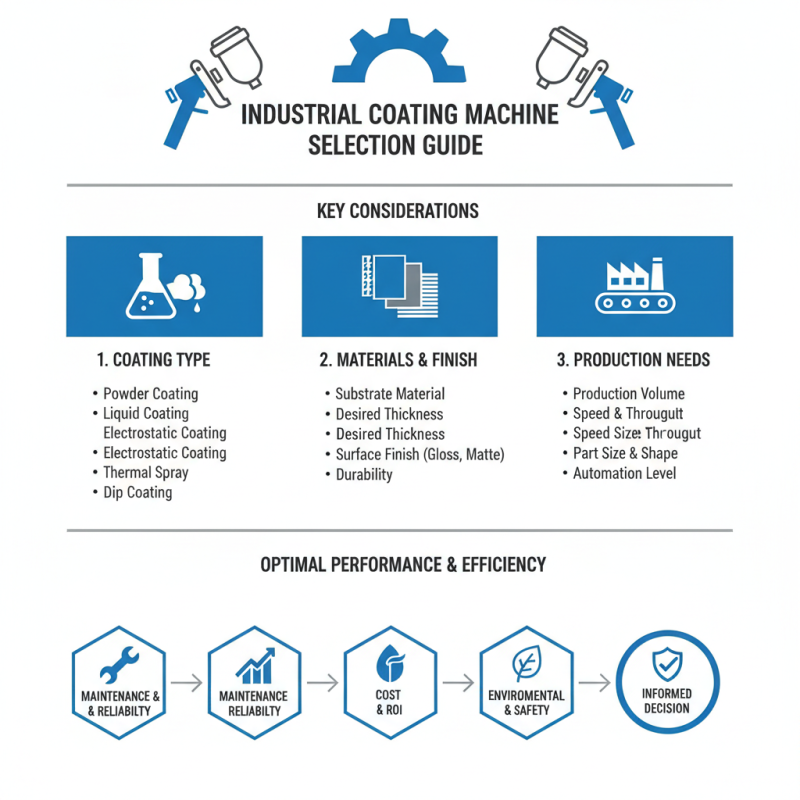

When selecting an industrial coating machine, several key factors must be taken into account to ensure optimal performance and efficiency in your manufacturing processes. First, assess the type of coating you will be applying, as different machines are designed for specific applications such as powder coating, liquid coating, or electrostatic coating. Understanding the materials involved, as well as the desired finish, will guide you toward a machine that meets your production requirements effectively.

Another important consideration is the production capacity of the machine. Evaluate your manufacturing volume and throughput needs to choose a machine that can handle your workload without bottlenecks. Additionally, examine the machine's energy efficiency and maintenance requirements. A machine that consumes less energy and is easy to maintain can significantly reduce operational costs over time, making it a smart investment for your manufacturing facility. Lastly, consider the level of automation offered by the machine, as advanced automation features can enhance consistency, reduce labor costs, and improve overall productivity.

Maintaining your industrial coating equipment is essential for ensuring its longevity and optimal performance. Regular maintenance checks can prevent malfunctions that may lead to costly downtime. One of the most important aspects is cleaning the machinery regularly to avoid buildup of coatings that could affect application quality. Additionally, keep an eye on wear and tear of components, as timely replacements can prevent larger failures that disrupt manufacturing processes.

When considering upgrades, focus on technology that enhances efficiency and precision in coating applications. Investing in the latest controls and automation can significantly reduce waste and improve consistency. It's also worth exploring modular systems that allow for scalability, enabling your equipment to adapt as your production needs evolve.

**Tips:**

1. Implement a routine maintenance schedule that includes detailed inspections and necessary repairs to extend the life of your equipment.

2. Train your staff on proper use and maintenance protocols to ensure everyone is equipped to handle the machinery effectively.

3. Document all maintenance activities and upgrades to track performance and identify areas for improvement over time.

This chart illustrates the percentage of manufacturers utilizing various types of industrial coating machines in their processes. The data highlights the importance of maintaining and upgrading these machines for optimal performance.