The optical technology sector is on the brink of a revolutionary transformation, primarily driven by advancements in manufacturing processes, particularly the utilization of Lens Coating Machines. As reported by MarketsandMarkets, the global lens coating market is projected to reach USD 7.8 billion by 2025, growing at a CAGR of 6.1%. This growth is attributed to the increasing demand for high-quality optical devices across various applications, including eyeglasses, cameras, and automotive systems. Advanced lens coating techniques enhance optical performance by providing antireflective, scratch-resistant, and hydrophobic properties, thereby significantly improving the user experience and durability of lenses. The integration of automated Lens Coating Machines not only accelerates production rates but also ensures consistent quality and precision, which are critical in meeting the evolving demands of consumers and industries alike. As the industry embraces these innovations, understanding their impact on the future of vision becomes essential for stakeholders across the optical spectrum.

The evolution of lens coating technologies has significantly transformed the landscape of optical manufacturing. Early lens coatings were primarily aimed at reducing glare and enhancing light transmission through simple designs that offered limited benefits. As the demand for high-performance optical devices grew, manufacturers began to explore more sophisticated methods. Innovations in chemical vapor deposition (CVD) and sputtering techniques allowed for the application of multi-layer coatings, dramatically improving durability, scratch resistance, and anti-reflective properties.

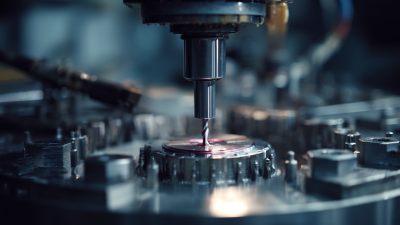

In recent years, advanced lens coating machines have emerged, integrating automation and precision engineering into the production process. These machines not only increase the efficiency of coating application but also enable the development of customized solutions tailored to specific optical requirements. With the rise of smart and connected devices, the ability to produce lenses with specialized coatings that offer advanced functionalities, such as anti-fogging or hydrophobic properties, has become critical. This progression in coating technology underscores the vital role of precision machinery in enhancing optical performance and meeting the evolving demands of various industries.

The advancements in lens coating machines are poised to revolutionize optical technology, establishing new benchmarks in precision and durability. Recent developments highlight China's emergence as a leading innovator in advanced industries, substantially enhancing the capabilities of domestic companies and universities. This surge in innovation is instrumental in optimizing the lens manufacturing process, ensuring that coatings are applied with unprecedented accuracy and effectiveness.

As we approach significant industry events like IMTEX 2025, the spotlight will be on cutting-edge coating solutions that not only improve the performance of optical lenses but also significantly reduce production time. The continuous evolution of these machines signifies a pivotal shift towards automation and smart manufacturing in the optical sector.

**Tip:** When selecting lens coating methods, consider the environmental impact and sustainability of materials, as well as the efficiency of the processes involved. Emphasizing the integration of eco-friendly practices can not only enhance product appeal but also contribute to long-term business viability. **Tip:** Stay updated with global trends and market reports, as understanding these dynamics can aid in making informed decisions about investments in advanced optical technologies.

The advancement of lens coating technology plays a critical role in enhancing lens performance and durability within the optical industry. According to the Global Optical Coatings Market Analysis report by MarketsandMarkets, the optical coating industry is projected to reach $20.43 billion by 2025, driven by the increasing demand for high-performance optical products in various applications including consumer electronics, automotive, and healthcare. These advanced coatings not only improve the optical clarity of lenses but also provide resistance to scratches, glare, and other environmental factors that can degrade performance over time.

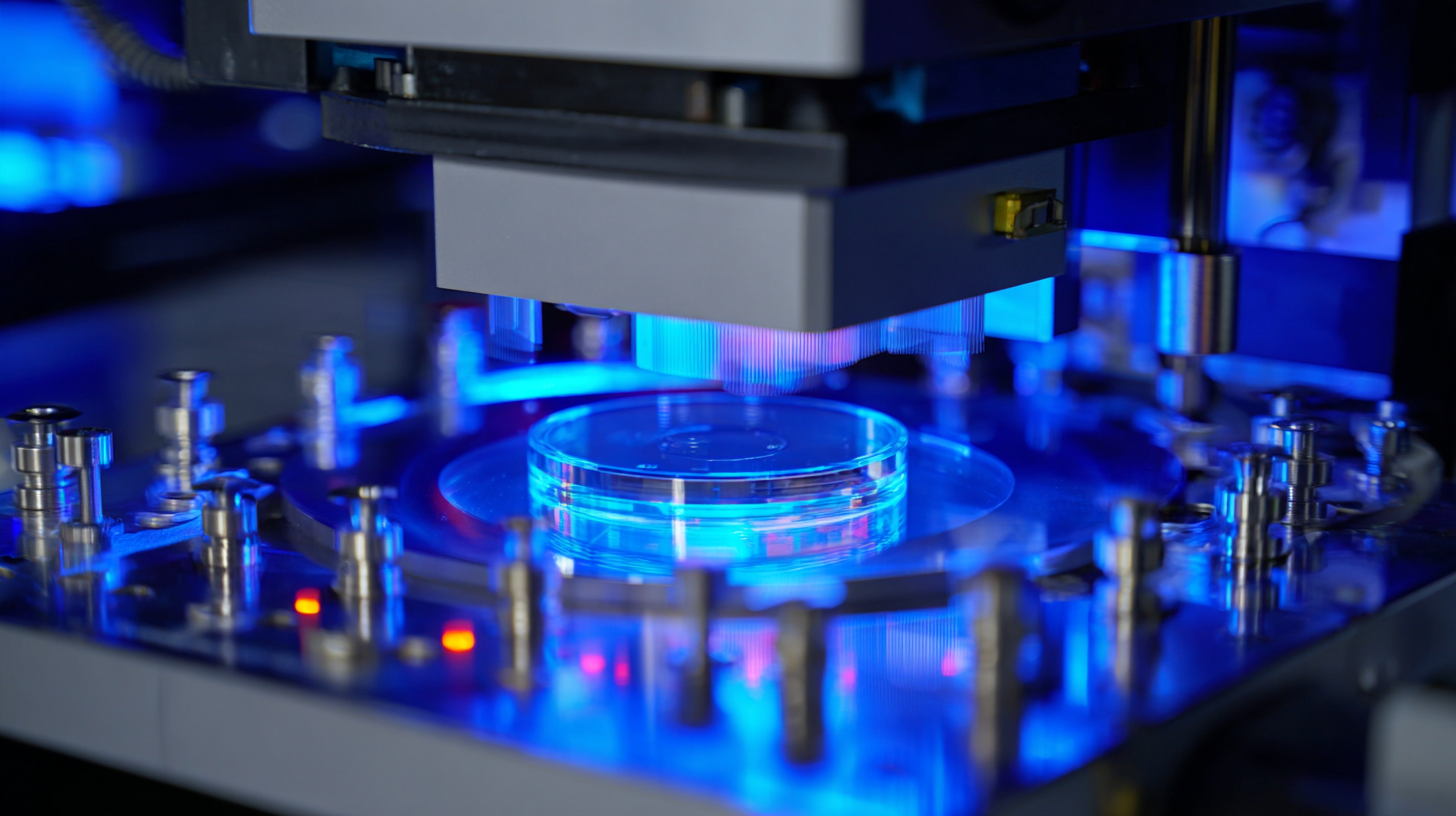

Recent innovations in lens coating machines have enabled manufacturers to apply multi-layer coatings with precision. A study conducted by Photonics Media reveals that lenses treated with advanced coatings exhibit a reduction in reflectivity by up to 99.9%, significantly enhancing light transmission. Additionally, such coatings can extend the lifespan of lenses by up to 50%, ensuring greater durability and lower replacement costs for consumers. This shift towards high-performance coatings is indicative of the evolving optical landscape, where customers increasingly seek products that blend durability with optical excellence.

As the optical technology sector continues to evolve, the importance of sustainability in the production of optical lens coatings cannot be overstated. The traditional methods of coating lenses often involve hazardous chemicals and substantial energy consumption. However, advancements in lens coating machines are enabling manufacturers to adopt greener practices. By integrating high-efficiency technologies and eco-friendly materials, producers can significantly reduce their environmental footprint while maintaining the performance and quality of optical products.

Moreover, the push towards sustainability is prompting innovations in manufacturing processes. For instance, the use of water-based coatings and the implementation of closed-loop systems help minimize waste and enhance resource efficiency. Such practices not only align with global sustainability goals but also offer cost-saving benefits in the long run. As consumers increasingly prioritize environmentally conscious products, the advancement of lens coating technology will be critical in meeting market demands while fostering an eco-friendly approach in the optical industry.

As advancements in optical technology continue to reshape our understanding of vision and imaging, the role of lens coating applications becomes increasingly critical. The development of advanced lens coating machines has revolutionized the production processes, enabling the creation of coatings that enhance the functionality and durability of optical devices. Innovations such as anti-reflective and hydrophobic coatings are now commonplace, providing consumers with clearer visuals and superior protection against environmental factors.

Looking to the future, we can anticipate several trends influencing optical technology and lens coating applications. One significant shift is the integration of smart coatings that can adapt to changing conditions, potentially altering their properties based on light exposure or temperature. This adaptability could lead to breakthroughs in areas like augmented reality and enhanced vision systems in vehicles, offering users a dynamic and customized experience. Additionally, sustainability is becoming a focal point, prompting manufacturers to adopt eco-friendly materials and processes in lens production. As the demand for high-performance optical solutions grows, these trends will play a pivotal role in shaping the next generation of vision-related technologies.