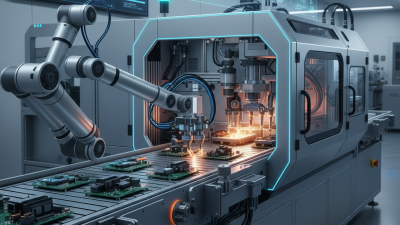

In the world of industrial equipment, the importance of the Cutting Machine Battery cannot be overstated. Experts like John Miller, a renowned technician in the field, state, “A reliable battery is the lifeline of any cutting machine.” Without it, performance suffers.

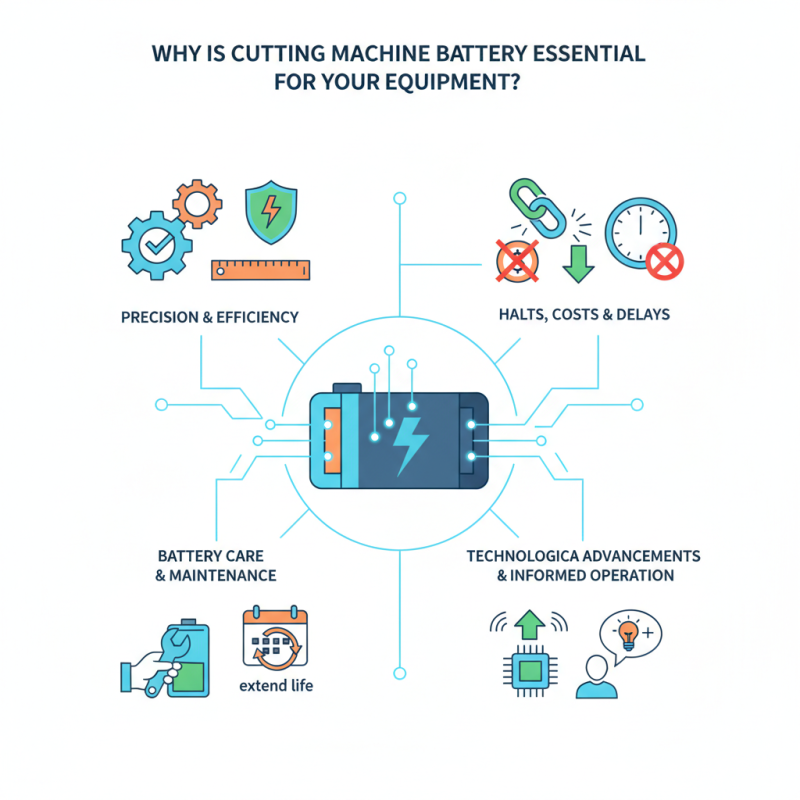

A well-functioning Cutting Machine Battery ensures precision and efficiency. When the battery fails, operations may halt. This can result in unexpected costs and delays. Every cutting task requires power. Without a dependable battery, the entire process becomes unpredictable.

Many operators overlook battery care. Regular maintenance is essential to extend battery life. Ignoring this can lead to frustrating situations. As technology evolves, so do battery standards. Thus, staying informed about advancements in Cutting Machine Battery technology is crucial. An informed operator avoids mishaps and enhances productivity. The journey towards optimal performance starts with understanding the very basics.

Battery maintenance for cutting machines is crucial for optimal performance. Regularly checking battery health can extend its lifespan. A report by the Battery Industry Association states that inadequate maintenance can reduce battery life by up to 30%. This leads to unexpected downtimes and increased operational costs.

Keeping connections clean and checking for corrosion are simple tasks. They often get overlooked. Neglecting these can lead to poor power delivery. According to industry standards, a well-maintained battery can deliver up to 20% more power. This certainly impacts efficiency on the job site. Batteries should also be charged according to manufacturer guidelines to ensure peak performance.

Ignoring battery care doesn't just hurt productivity; it can also compromise safety. A weak battery can fail during critical operations. Data shows that equipment failures due to battery issues account for 15% of all downtime. It’s easy to overlook battery maintenance in busy environments. Yet, this oversight can lead to significant setbacks. Keeping a regular maintenance schedule might seem tedious, but it pays off in performance and safety.

Battery quality significantly influences cutting performance. A high-quality battery ensures that your cutting machine operates efficiently. It provides consistent power and reduces the risk of interruption during critical projects. When a battery can deliver the required voltage and current, it enhances cutting speed and precision.

Poor battery quality can lead to inconsistent cuts. This affects not only the final product but also the overall efficiency. If the battery discharges quickly, the user may face extended downtime. Replacing a low-quality battery frequently also adds to costs. Investing in a reliable battery can minimize these issues.

Moreover, a well-maintained battery contributes to the longevity of the machine. Over time, low-quality batteries can cause damage to the equipment. This can result in costly repairs and reduced performance. Ensuring the right battery choice is crucial for maintaining cutting equipment. A thoughtful selection will lead to better results and more satisfaction.

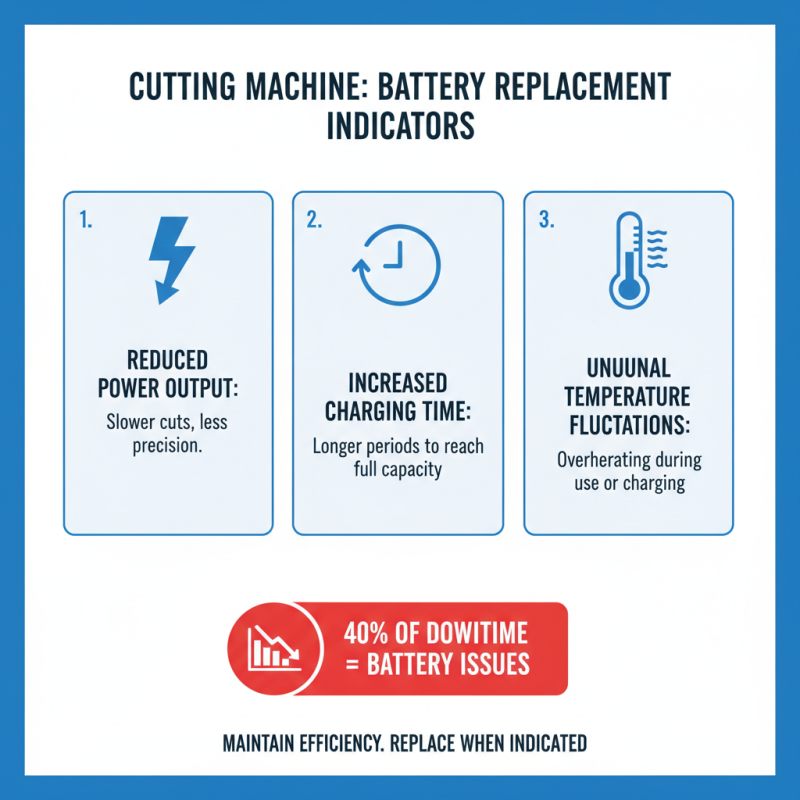

Recognizing when to replace your cutting machine battery is crucial for maintaining operational efficiency. Reports show that around 40% of equipment downtime is linked to battery issues. Factors such as reduced power, increased charging time, and unusual temperature fluctuations indicate your battery may be nearing the end of its life.

Watch for signs like dimming lights or sluggish performance. These are often symptoms of a weakened battery. The average lifespan of industrial batteries is between 2 to 5 years, depending on usage and maintenance practices. A sudden drop in performance can disrupt projects, leading to delays and additional costs. Ignoring these signs can lead to larger problems down the road.

Consider the cost of ignoring battery health. Studies indicate that replacing a battery before it fails can save up to 25% in operational costs. Timely replacements not only ensure productivity but also enhance the safety of your equipment. If you notice any warning signs, it might be time to take action.

Battery care is crucial for cutting machines. A well-maintained battery enhances performance and prolongs equipment life. Regular inspection is important. Check for corrosion or leaks. If you notice any issues, address them promptly.

Tips for battery care: Clean terminals regularly to prevent buildup. Use a soft brush for this task. Keep batteries charged but avoid overcharging. An overcharged battery can swell and may leak. Monitor the charging cycles. Too many cycles can shorten battery life.

Consider replacement if you notice reduced performance. A weak battery can hinder productivity. Use high-quality replacements, as they can make a difference. Improper disposal of old batteries can cause harm. Research local guidelines to dispose of them correctly. Taking these steps ensures the longevity of your cutting machine.

| Battery Type | Voltage | Capacity (Ah) | Average Lifespan (Years) | Replacement Frequency |

|---|---|---|---|---|

| Lithium-ion | 24V | 10 Ah | 3-5 | Every 3-5 years |

| Lead Acid | 12V | 20 Ah | 3-4 | Every 3-4 years |

| NiMH | 18V | 8 Ah | 2-3 | Every 2-3 years |

| Lithium Iron Phosphate | 36V | 15 Ah | 5-10 | Every 5-10 years |

Investing in cutting machine batteries offers significant returns. According to a recent industry report, over 35% of machine downtime is due to battery failure. This leads to increased costs and lost productivity. For businesses, these interruptions can translate to hundreds of thousands of dollars annually. Better batteries improve reliability and efficiency, ultimately saving money.

When considering the cost-benefit analysis, think about long-term savings. Quality batteries last longer and require less frequent replacements. A study revealed that high-quality batteries can reduce operating costs by up to 25%. This is not just an upfront investment; it's a strategy to enhance the overall performance of your equipment.

Tips: Regular maintenance can maximize battery life. Check connections and clean terminals. Also, avoid extreme temperatures, which can degrade battery efficiency.

Investing in the right cutting machine battery also means considering the environmental impact. Sustainable options can reduce your carbon footprint. Yet, the initial price may deter some. Reflecting on the trade-offs is crucial. A short-term view can lead to costly consequences. Ensure your choice aligns with your operational goals.

This chart presents a cost-benefit analysis of investing in cutting machine batteries, illustrating different cost factors and the potential benefits in terms of productivity gain and operational efficiency.