In today's competitive manufacturing landscape, selecting the right Liquid Coating Machine is critical for ensuring product quality and operational efficiency. According to a report by MarketsandMarkets, the liquid coating market is projected to grow from $19.68 billion in 2020 to $28.21 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth underscores the importance for businesses to invest in advanced liquid coating technologies that can meet evolving market demands while improving productivity and reducing waste.

Industry expert Dr. Emily Collins, a leading researcher in coating technologies, emphasizes the significance of making informed decisions in this domain. She states, "Choosing the right Liquid Coating Machine can not only enhance the quality of your end products but also provide substantial cost savings in the long run." With a multitude of options available, businesses must consider factors such as machine type, application methods, and efficiency rates to determine the best fit for their unique operational needs.

As the Liquid Coating Machine market continues to evolve, understanding these key considerations is essential for companies looking to stay ahead of their competition. By leveraging expert insights and industry data, businesses can navigate this complex landscape and make strategic decisions that foster growth and innovation.

When selecting a liquid coating machine for your business, it is essential to first understand your specific coating needs. Industries such as automotive, aerospace, and electronics rely heavily on precise liquid coating applications to enhance product durability and aesthetics. According to a report by Research and Markets, the global liquid coating market is expected to reach $157.3 billion by 2025, with a compound annual growth rate (CAGR) of 5.5%. This growth emphasizes the increasing demand for efficient and tailored coating solutions across various sectors.

Identifying factors such as the type of material being coated, the desired finish, and the scale of production will guide your choice significantly. For instance, businesses focusing on high-volume production may require automated systems capable of delivering consistent finishes at an accelerated pace. The American Coatings Association suggests that investing in machinery that offers versatility—such as the ability to switch between different coating types—can enhance operational efficiency, catering to fluctuating market demands.

Moreover, understanding the regulatory compliance of liquid coatings in your industry is crucial, as it can affect machine specifications and maintenance practices. Continuously evaluating your coating needs will ensure that you choose a machine that not only meets current requirements but also accommodates future growth.

When selecting a liquid coating machine for your business, it is essential to focus on key features that can significantly enhance the efficiency and quality of your operations. One of the primary considerations is the machine's application method. Different machines cater to various application techniques such as spray, dip, or roller coating. Understanding the specifics of each method allows you to decide the best fit for your products and the level of precision required.

Another critical feature to examine is the machine's capacity and speed. The production volume of your business will determine the necessary throughput and drying times. Machines that offer adjustable speed settings can be advantageous, allowing you to adapt to varying project requirements. Additionally, consider the machine's ease of use and maintenance. A user-friendly interface and readily accessible parts can minimize downtime and enhance productivity. Evaluating these key features will ensure that you choose a liquid coating machine that meets your operational needs and supports your business growth effectively.

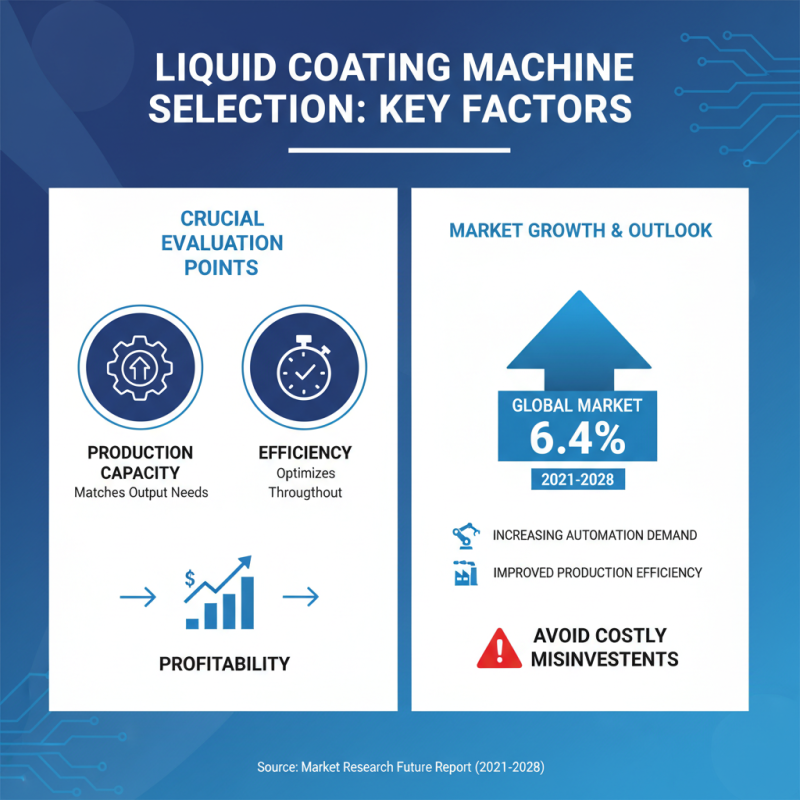

When selecting a liquid coating machine, it is crucial to evaluate production capacity and efficiency, as these factors directly impact your business's operational success and profitability. According to a report by Market Research Future, the global liquid coating equipment market is projected to expand at a CAGR of 6.4% from 2021 to 2028. This growth is anticipated due to increasing demand for automation and improved production efficiency in various industries. Understanding your production needs and how a coating machine aligns with those requirements can help avoid costly misinvestments.

One key consideration is the machine's throughput, which is typically measured in liters per hour. For instance, machines with higher throughput capabilities can substantially reduce operational time and increase output, essential for meeting market demands. Additionally, industry benchmarks suggest that machines should ideally achieve efficiency rates of 85% or higher. This statistic involves assessing not only the speed of application but also the precision and consistency of the coating process. A thorough analysis of these productivity metrics will allow businesses to optimize their manufacturing processes, leading to enhanced product quality and lower waste levels.

When selecting a liquid coating machine for your business, it's essential to understand the various technologies available. There are several liquid coating methods, each with distinct advantages and applications. Conventional systems, such as spray coating, are widely used due to their versatility and ability to achieve smooth finishes. However, they can produce overspray, leading to material wastage and increased cleanup time. For businesses focused on efficiency and sustainability, equipment that utilizes electrostatic spray technology can minimize overspray and enhance material utilization while providing consistent and even coating.

Another notable technology is the use of immersion coating systems, which offer a uniform coating layer by submerging the substrate in a liquid bath. This method is particularly effective for complex geometries or intricate parts, allowing for thorough coverage without missing hard-to-reach areas. On the other hand, curtain coating machines utilize a thin curtain of liquid that substrates pass through, offering high-speed application and reduced waste. Understanding the specific needs of your production line—including the type of materials you are working with and your desired finish—will assist in determining which coating technology will be the most beneficial and cost-effective for your operations.

| Tip | Consideration | Benefits | Limitations |

|---|---|---|---|

| 1. Assess Your Production Needs | Volume of Production | Optimized capacity | Might overestimate needs |

| 2. Evaluate Coating Types | Water-based vs. Solvent-based | Environmentally friendly options | Some may have slower drying times |

| 3. Consider Machine Size | Footprint and Size | Fits well into your production area | Limited space can restrict options |

| 4. Check for Automation Features | Fully automated vs. manual | Increased efficiency | Higher initial cost |

| 5. Consider Maintenance Needs | Ease of cleaning and repairs | Reduced downtime | May require specialized tools |

| 6. Assess Energy Efficiency | Electric vs. Gas | Lower operating costs | May not be available in all models |

| 7. Look for Warranty Options | Length and coverage | Peace of mind | Might not cover all parts |

| 8. Evaluate Cost of Ownership | Total expenses over time | Budget-friendly choices | May require upfront investment |

| 9. Research User Reviews | Feedback from existing users | Real-world performance insights | Potential biased opinions |

| 10. Consult with Experts | Seek professional advice | Informed decision-making | Consultation fees may apply |

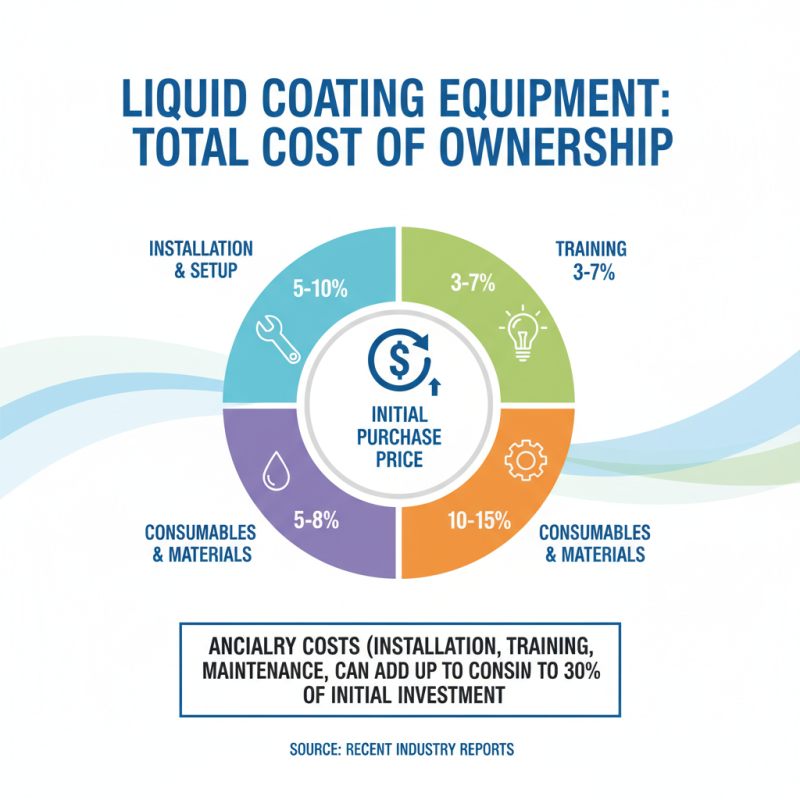

When considering the investment in liquid coating equipment, one of the foremost aspects to focus on is budgeting. According to recent industry reports, the total cost of ownership for liquid coating machines typically encompasses more than just the purchase price. Businesses should factor in expenses related to installation, training, maintenance, and consumables, which can account for up to 30% of the initial investment over time. Understanding these ancillary costs is crucial for creating a comprehensive budget that ensures operational efficiency and sustainability.

Moreover, data from market analysis suggests that companies can expect a return on investment (ROI) in the range of 20-40% within the first two years of purchasing liquid coating equipment, depending on application and usage rates. This highlights the importance of selecting equipment that not only fits the current operational needs but also aligns with the long-term growth strategy of the business. Investing in more advanced machinery might necessitate a higher upfront cost, yet can lead to significant savings in labor and material costs while increasing production capacity and quality. Taking the time to analyze these financial factors will provide a clearer picture of how liquid coating equipment can contribute to overall profitability.