In the competitive landscape of powder coating, selecting the right Coating Powder Machine can significantly influence the efficiency and quality of your production processes. Industry expert and consultant, Dr. Emily Tran, emphasizes, "The right equipment not only enhances productivity but also ensures a superior finish, which is crucial in maintaining customer satisfaction." This insight underscores the importance of making an informed choice when investing in machinery for your business.

When exploring the various options available, it is essential to consider several key factors, including the machine's specifications, production capacity, and operational ease. With advancements in technology, today's Coating Powder Machines offer features that can optimize your workflow and reduce waste. By understanding the distinct attributes of each machine and how they align with your specific needs, you can make a decision that not only meets your current requirements but also supports future growth.

Ultimately, the right Coating Powder Machine is an investment in your business's long-term success. By leveraging expert knowledge and industry insights, you can navigate the decision-making process with confidence, ensuring that you choose a machine that will enhance both your product quality and operational efficiency.

When selecting a coating powder machine, it's crucial to understand the various types available on the market to ensure the right fit for your business needs. There are primarily three categories of coating powder machines: manual, automatic, and semi-automatic. Manual machines are suited for small-scale operations or startups, offering flexibility and lower upfront costs. However, they may require more labor and time to operate effectively. According to a report by MarketsandMarkets, the demand for automatic coating machines is on the rise, projected to grow at a CAGR of 6.7% from 2022 to 2027, largely due to their efficiency and consistency in production.

Automatic coating powder machines typically provide high throughput and better quality control, making them ideal for medium to large-scale operations. These machines are equipped with advanced technologies that allow real-time monitoring and adjustments during the coating process, reducing wastage and enhancing productivity. A 2023 study by ResearchAndMarkets highlighted that the adoption of automatic systems leads to a significant decrease in labor costs and an improvement in application speed, thus boosting overall profitability.

Semi-automatic machines serve as a middle ground, combining elements of both manual and fully automatic machines. They provide operators with a level of control while still benefiting from some automated features, making them suitable for businesses that require flexibility without sacrificing efficiency. Understanding these types of coating powder machines is essential for making an informed decision that aligns with your operational goals and production demands.

| Type of Coating Powder Machine | Key Features | Ideal Applications | Pros | Cons |

|---|---|---|---|---|

| Electrostatic Powder Coating Machine | High transfer efficiency, adjustable voltage | Automotive parts, metal furniture | Cost-effective, uniform coating | Requires skilled operators |

| Fluidized Bed Coating Machine | Uniform coating, easy product handling | Molded parts, small components | Better control over thickness | Limited to specific applications |

| Spray Coating Machine | Versatile, adjustable spray pattern | Large surfaces, complex shapes | Highly adaptable, quick process | May require cleaning between colors |

| Manual Powder Coating Machine | Portable, user-friendly | Small batch productions | Low cost, flexible use | Less efficient for large volumes |

When selecting a coating powder machine for your business, it is essential to evaluate key features and specifications that align with your operational needs. One crucial aspect to consider is the machine's output capacity. According to a report by Grand View Research, the global powder coating market is expected to reach $25.8 billion by 2025, which highlights the increasing demand for efficient and high-capacity coating solutions. Machines that can handle larger volumes often have increased throughput and reduced downtime, making them a valuable investment.

Another important factor is the machine's temperature control and preheating capabilities. Precise temperature regulation is vital for ensuring that the powder adheres evenly, resulting in a more uniform finish. A study by the Powder Coating Institute indicates that inconsistencies in temperature can lead to defects, ultimately impacting product quality and increasing rework costs. Choosing a machine with advanced control systems can mitigate these issues, enabling your operation to maintain high standards and improve overall efficiency.

Lastly, consider the versatility of the coating powder machine in terms of the range of materials it can accommodate and the types of finishes it can produce. A more adaptable machine can facilitate a wider array of applications, from automotive parts to furniture manufacturing. As noted in a market analysis by Mordor Intelligence, businesses that invest in flexible machinery can pivot more easily to meet evolving customer demands, ultimately positioning themselves for sustainable growth in a competitive landscape.

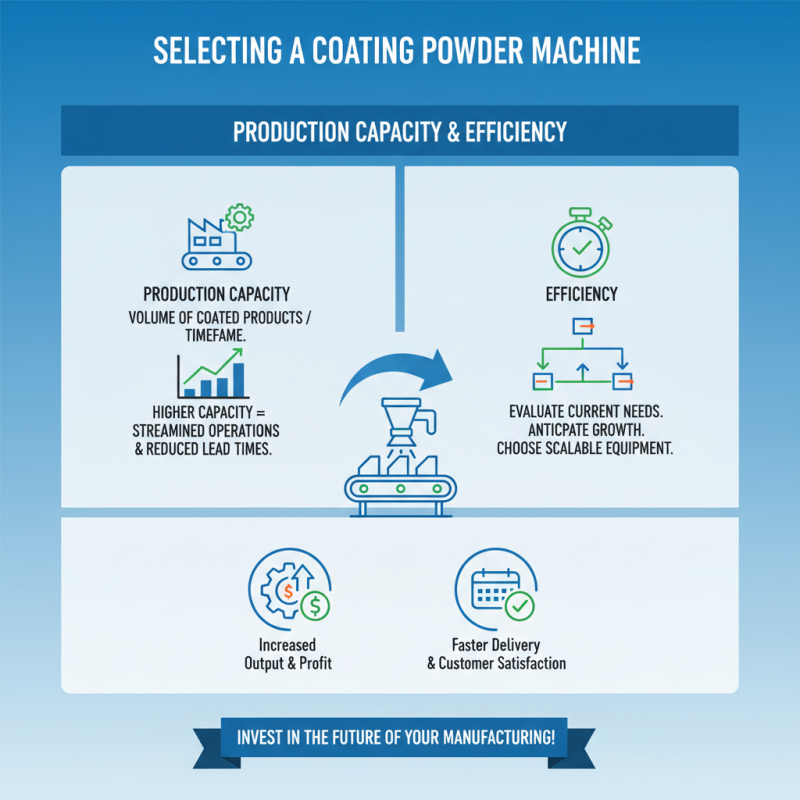

When selecting a coating powder machine for your business, assessing the production capacity and efficiency of the equipment is crucial. The production capacity relates to the volume of coated products that the machine can handle within a specific timeframe. A machine with higher capacity can streamline your operations and reduce lead times. Therefore, evaluate your current production needs and consider whether you anticipate growth in your manufacturing output. Opt for equipment that not only meets your immediate demands but also has the potential for scalability.

Efficiency is another essential factor to consider. An efficient coating powder machine minimizes waste, saves energy, and reduces operational costs. Look for features that enhance productivity, such as quick changeover times and consistent coating quality. Additionally, investing in machines with user-friendly interfaces can facilitate smoother operation and quicker training for your staff.

Tip: Always conduct a thorough review of any machine’s specifications and performance metrics before making a purchase. Consulting with manufacturers or industry experts can provide valuable insights into which machines may best suit your specific requirements.

When choosing the right coating powder machine for your business, it’s essential to consider the maintenance requirements and support options available. According to industry reports, more than 40% of businesses face unexpected downtime due to inadequate maintenance strategies. This statistic highlights the importance of selecting a machine that not only meets production needs but also offers easy maintenance access and a reliable support system. A machine designed with user-friendly maintenance features can significantly reduce the time and cost associated with repairs and upkeep.

Furthermore, ensure that the manufacturer provides comprehensive support options, including training, troubleshooting, and spare parts availability. A report from the Powder Coating Institute indicates that companies providing robust after-sales support can enhance operational efficiency by up to 35%. By investing in a coating powder machine backed by solid technical support, businesses can mitigate risks associated with machinery failures and ensure a smoother production process. Ultimately, assessing maintenance requirements and support mechanisms will play a crucial role in the longevity and performance of your coating machinery.

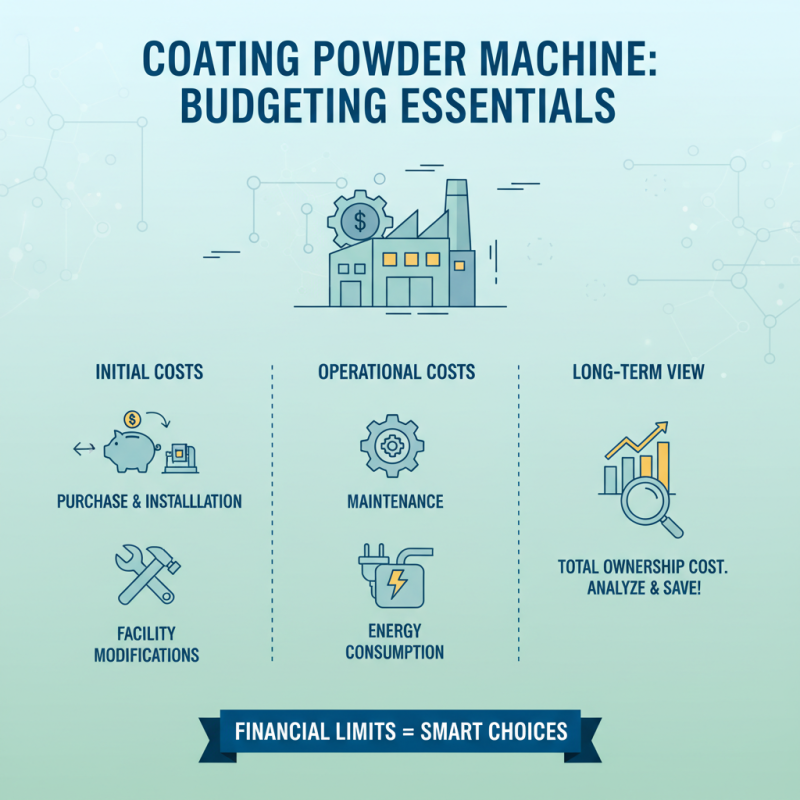

When selecting a coating powder machine for your business, it's crucial to first analyze your budget constraints. Understanding your financial limits will help you narrow down the options that not only fit your operational needs but also align with your monetary resources. A detailed budget assessment includes considerations for the initial purchase cost, installation expenses, and any required modifications to your facility. Additionally, think about the recurring costs, like maintenance and energy consumption, which can significantly impact your bottom line.

Cost-effectiveness should be a driving factor in your decision-making process. It's essential to evaluate the potential return on investment by considering the efficiency of the machinery. Models that offer superior performance and durability may come with a higher upfront cost, but they can save money in the long run through reduced maintenance costs and increased production rates. Also, consider how well the machine integrates with your existing processes and whether it can scale with your business needs. Balancing these factors will enable you to make a more informed choice, ensuring that you invest in a coating powder machine that not only suits your current budget but also supports your growth objectives.