Choosing the right Stent Coating Machine is crucial for manufacturing success. A stent's performance heavily relies on its coating quality. Selecting a machine that meets your specific needs can be challenging and requires careful consideration.

You need to assess various factors. For instance, the type of coating material is essential. Different machines handle different materials effectively. Additionally, production speed is a key component. A machine that processes quickly saves time and increases output.

Yet, not all machines are perfect. Some may have a steep learning curve, making operations difficult. Others might lack versatility, limiting your options. Reflecting on these points helps you make an informed choice. Investing in the right Stent Coating Machine can significantly enhance your production line.

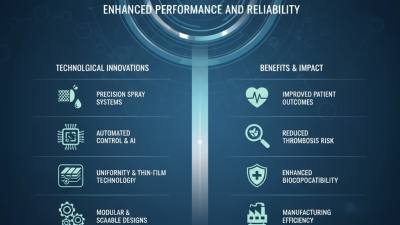

Stent coating machines play a critical role in the medical device manufacturing process. They apply specialized coatings to stents that enhance biocompatibility and reduce the risk of rejection. This process is essential for ensuring the longevity and efficacy of stents in patients. A well-functioning coating machine greatly impacts the quality of the final product.

The importance of these machines cannot be overstated. Without them, the production of effective stents would be compromised. Manufacturers must consider various aspects when selecting a coating machine. For instance, factors like precision, consistency, and ease of maintenance matter greatly. Some machines may struggle with uniformity in coating thickness, leading to potential issues later.

Finding the right machine also involves reflection. Not every option is suitable for every need. Budget constraints often limit choices. Balancing cost and quality is challenging. Some manufacturers may opt for cheaper machines, only to face difficulties in the long run. Prioritizing quality surely pays off.

Choosing the right stent coating machine requires careful consideration. Begin by assessing your production capacity. How many stents do you need to coat? A high-capacity machine is essential for large-scale production. Smaller operations might benefit from more compact models.

Additionally, look into the types of coatings your machine can handle. Different applications require specific materials. Some machines may only support a narrow range of coatings. This limitation can lead to significant challenges.

Another factor is the machine’s ease of use. User-friendly interfaces can save time in training staff. However, sometimes these features come at a higher cost. Don’t overlook maintenance requirements either. More complex machines might require frequent servicing. Reflect on whether your team can manage these needs effectively.

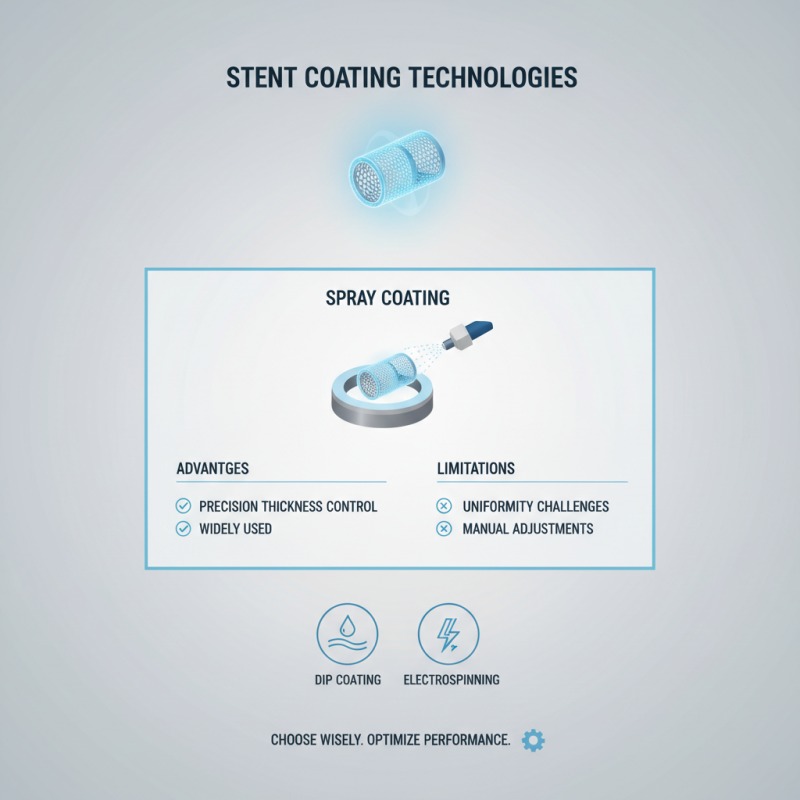

When selecting a stent coating machine, it is crucial to understand the different types of coating technologies available. Each technology offers unique advantages and limitations. For instance, spray coating is widely used in the industry. It allows for precise control over the coating thickness. However, achieving uniformity can be challenging. Operators may need to make several adjustments during the process.

Another popular technology is dip coating. This method is generally simpler and can coat multiple stents at once. Yet, it might not provide the desired thickness for every application. Some manufacturers report inconsistencies in the final product. Roll-to-roll coating stands out for high-volume production. It improves efficiency but requires a significant investment in machinery. The learning curve can be steep for operators unfamiliar with this process.

Understanding these technologies is vital for making an informed choice. Each option requires careful consideration of production needs, desired outcomes, and available resources. Evaluating the potential drawbacks is equally important. Balancing efficiency and quality remains a constant challenge in this evolving field.

When selecting a stent coating machine, evaluating the manufacturer’s reputation is critical. A strong reputation often indicates reliability and quality. Look for companies with a proven track record in the industry. Seek out customer reviews and testimonials. These insights can reveal how well the machine performs in real-world conditions.

Customer support services should also be part of your evaluation. Friendly and efficient support can save time when issues arise. Check if the manufacturer offers training and troubleshooting assistance. Quick responses to inquiries are essential. It’s frustrating to feel unsupported when facing challenges with new equipment. Sometimes, companies might promise extensive support but deliver very little. Keep this in mind during your decision-making process. Engaging directly with support representatives can provide further clarity.

Making an informed choice means being aware of potential shortcomings. Not all manufacturers will meet your expectations. Take the time to ask pointed questions. Understand their service guarantees and experience in handling problems. This diligence can prevent future headaches in your manufacturing operation.

When budgeting for a stent coating machine, several factors must be considered. The initial cost varies significantly based on machine features, with prices ranging from $50,000 to over $200,000. According to a recent industry report, advanced machines with automation capabilities typically cost more. However, they often enhance efficiency and precision, potentially saving money in the long run.

Maintenance expenses can also add to the total cost. Regular maintenance is essential to avoid downtime, which can be costly. Reports indicate that routine servicing can amount to 7-12% of the purchase price annually. It's crucial to factor this into your budget. Additionally, the cost of materials used in the coating process can vary. Some materials may be more expensive upfront but deliver better performance.

Training your personnel is another expense that’s often overlooked. Investing in proper training ensures optimal use of the machine, which can prevent costly mistakes. Data from industry surveys indicate that manufacturers who prioritize staff training see a 20% increase in production efficiency, offsetting initial costs over time.

| Feature | Description | Estimated Cost (USD) |

|---|---|---|

| Production Capacity | Able to coat 500 stents per hour | $150,000 |

| Coating Material Compatibility | Compatible with polymers and metals | Included |

| Ease of Operation | User-friendly interface with automation | Included |

| Maintenance Requirements | Annual maintenance needed, minimal parts replacement | $10,000 |

| Warranty Period | 2 years warranty with support | Included |

| Installation Cost | Cost of installation and calibration | $5,000 |

| Total Estimated Cost | Total expense including purchase and setup | $165,000 |