Choosing the right Thin Film Coating Machine can be a daunting task. There are many factors to consider before making your decision. Different applications require different features. For instance, some machines excel in uniform coating, while others focus on speed and efficiency.

Understanding your specific needs is crucial. Consider the materials you'll be working with. Is your focus on optics, electronics, or perhaps decorative finishes? Each area may demand distinct specifications. It's also important to reflect on your budget. High-end machines offer advanced features but may come at a cost.

Moreover, user-friendliness can be a significant factor. Some machines are difficult to operate, causing frustration. A well-designed interface can save you time and trouble. Evaluate reviews and feedback from current users. This insight can guide your decision. Remember, the best machine is not necessarily the most expensive. It should align with your unique needs and help you achieve your desired results.

When selecting a thin film coating machine, understanding your specific coating requirements is crucial. Different applications demand varying layer thicknesses, materials, and properties. According to a recent industry report, over 70% of manufacturers prioritize material compatibility in their operations. Not aligning your machine's capabilities with your material needs may lead to inefficient results.

Consider the substrate types you will use. Glass, metals, and ceramics behave differently under various conditions. A study highlighted that improper coating on substrate can reduce performance by up to 40%. This statistic emphasizes the importance of machine settings that accommodate different substrates.

Another factor is the desired coating uniformity. For applications like optics or electronics, maintaining consistent thickness is critical. A lack of precision can result in defects that decrease product reliability. Additionally, the learning curve of your team in operating these machines cannot be overlooked. Training is vital for maximizing a machine's potential. Balancing these elements will contribute significantly to your production quality and efficiency.

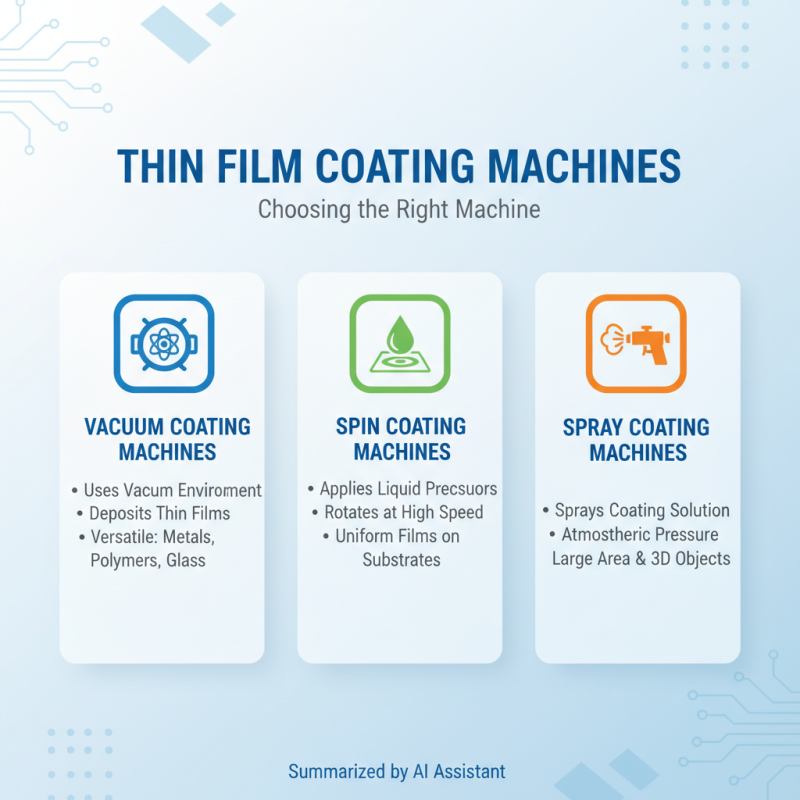

Choosing the right thin film coating machine can be overwhelming. Various types are available, each catering to different needs. For instance, vacuum coating machines are popular. They use a vacuum environment to deposit thin films. These machines are suitable for metals, polymers, and even glass.

Another type is the sputtering machine. It provides a thick and uniform coating. Sputtering machines work by ejecting atoms from a target material. These coatings can enhance the performance of optical and electronic devices. However, they can be complex to operate, requiring skilled personnel.

Then there are chemical vapor deposition systems. They create coatings through chemical reactions. This method can produce high-quality films but involves careful control of chemical processes. Users must regularly monitor these machines. Maintenance can be time-consuming, and mistakes may lead to quality issues. Reflecting on your specific needs is crucial. Each machine has strengths and weaknesses. Choosing the best option requires understanding your application.

When selecting a thin film coating machine, key features play a critical role. One significant aspect is the type of deposition method used. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are common techniques. According to a recent industry report, PVD holds about 60% of the market share due to its efficiency and quality output. Understanding the needs of your specific application can guide your choice.

Another essential feature to consider is the machine's scalability. Many operations require flexibility to adapt to varying production levels. A coating machine that can handle both small and large batches is valuable. Look for systems that allow quick adjustments, as this can reduce downtime. Reports indicate that flexibility in manufacturing can improve productivity by up to 30%.

Additionally, it's crucial to evaluate the machine's ease of use. User-friendly interfaces and straightforward maintenance procedures can save time and reduce errors. Some machines, despite their advanced features, are complicated and can lead to operator frustration. This can hinder production efficiency. Balancing advanced technology with simplicity is vital for long-term success.

Budgeting for thin film coating equipment can be complex. Prices can vary significantly based on features and capabilities. A recent industry report indicates that high-quality machines range from $50,000 to $500,000. Understanding your specific requirements is crucial. For example, a more precise coating process may justify higher spending.

Maintenance is another cost consideration. Ongoing expenses can include replacement parts and servicing. Some equipment may require additional software updates. Budgeting shouldn’t only account for initial purchase costs. It should encompass the total cost of ownership over the machine’s lifespan.

When evaluating costs, consider energy efficiency. Machines with lower energy consumption can lead to significant savings. Reports show that energy-efficient models can reduce operational costs by up to 25%. Make sure to ask about these figures. Choosing the right thin film coating machine demands thorough research and a clear understanding of all budget-related factors.

Maintaining a thin film coating machine is crucial for its longevity. Regular inspections are essential. Check for wear and tear in crucial parts. Dust and residue buildup can hinder performance. Create a schedule for cleaning and maintenance. Sometimes, it’s easy to overlook these details. A simple neglect can lead to costly repairs.

Support from manufacturers or service providers is invaluable. They can offer guidance on optimal usage. Technical support can resolve unexpected issues quickly. Delays in production can impact your overall workflow. Consider investing in extended warranty plans or service packages. However, not all support options are equally effective. Research customer reviews to gauge reliability.

Training your staff is another key aspect. Proper training ensures everyone understands the machine’s intricacies. Mistakes can happen, especially with complex setups. Encouraging team feedback can foster improvement. Regular training refreshers can mitigate risks. Taking these steps could enhance your operation's efficiency over time.