Choosing the right Spray Coating Equipment is a critical decision that can significantly influence the outcome of your application. Whether you are working in industrial manufacturing, automotive refinishing, or even DIY home projects, understanding the various options available in spray coating technology can help you achieve optimal results. The right equipment not only enhances the quality of the coating but also improves efficiency and reduces waste, making it indispensable in any coating project.

When selecting Spray Coating Equipment, it's essential to consider several factors, including the type of materials being used, the scale of the project, and the specific requirements of the application. Various aspects such as spray pattern, nozzle size, and air pressure can drastically affect the performance of the equipment and the finish quality. By carefully assessing these elements, you can ensure that you choose equipment that aligns with your project's demands and ensures a professional result.

In this outline, we will explore the key aspects to consider when selecting Spray Coating Equipment, provide insight into various types of equipment available, and highlight best practices for maximizing your investment in this essential technology.

When selecting spray coating equipment, it’s crucial to understand the various types available and their specific applications. Common types include air spray, airless spray, and electrostatic spray equipment. Air spray systems are known for their versatility and ability to produce a fine finish, making them ideal for intricate projects. According to a report by the Finishing Industries Association, over 40% of industrial coating applications still utilize air spray technology due to its reliability and quality in achieving uniform coverage.

Airless spray equipment, on the other hand, is efficient for larger surfaces and heavy coatings. It employs high pressure to atomize the paint, allowing for quick application on surfaces such as walls and machinery. Data from the Coating Association indicates that airless systems can increase productivity by up to 30% compared to air-based systems when handling thick coatings. Meanwhile, electrostatic equipment is particularly advantageous for applications requiring improved transfer efficiency. This method, which charges the paint particles, minimizes overspray and waste—data shows that it can achieve as much as 90% transfer efficiency, a significant reduction in material costs.

Tips: When choosing spray coating equipment, consider the surface type and size, the viscosity of the material to be applied, and the desired finish. Additionally, ensure that the equipment is compatible with the environment in which you will be working, such as ventilation and cleanliness. Always review manufacturer specifications and industry reports for a better understanding of performance before making a purchase decision.

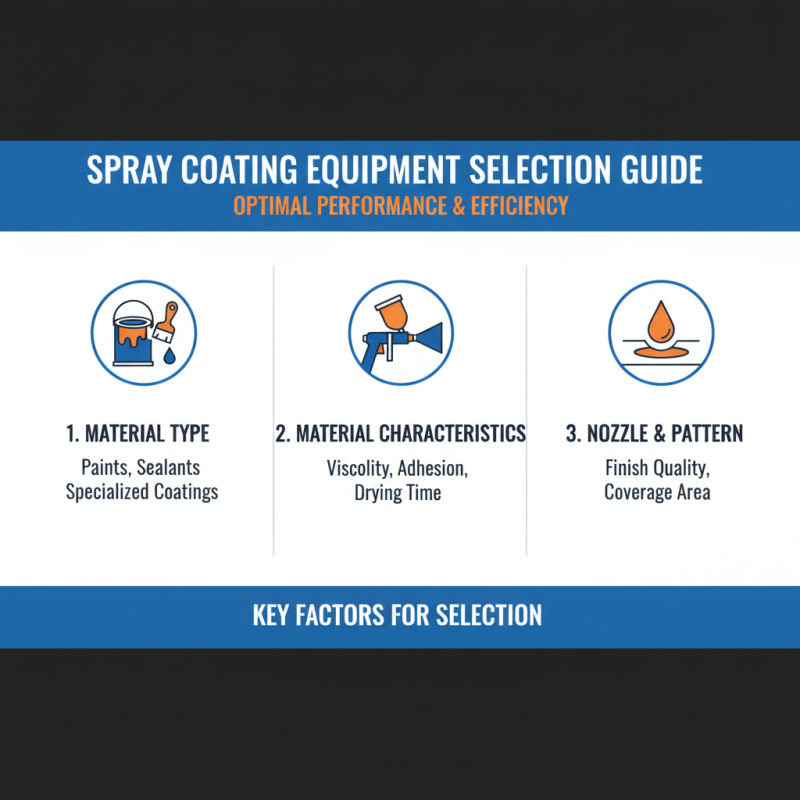

When selecting spray coating equipment for your application, it's essential to consider several key factors to ensure optimal performance and efficiency. First and foremost, evaluate the type of materials you’ll be using. Different coatings, such as paints, sealants, or specialized coatings, may require specific equipment suited for viscosity, adhesion, and drying time. Understanding your material's characteristics will help in choosing the right nozzle size and spray pattern, impacting both the finish and the coverage area.

Another critical factor is the operating environment of your application. Consider whether you need equipment designed for indoor or outdoor use, as this can affect durability and functionality. Additionally, assess the size and scale of your projects: smaller tasks may require compact, portable units, while larger operations may benefit from high-capacity systems that can handle greater volumes efficiently. It's also prudent to take into account maintenance and ease of use, ensuring that the equipment can be operated and maintained easily by your team without excessive downtime.

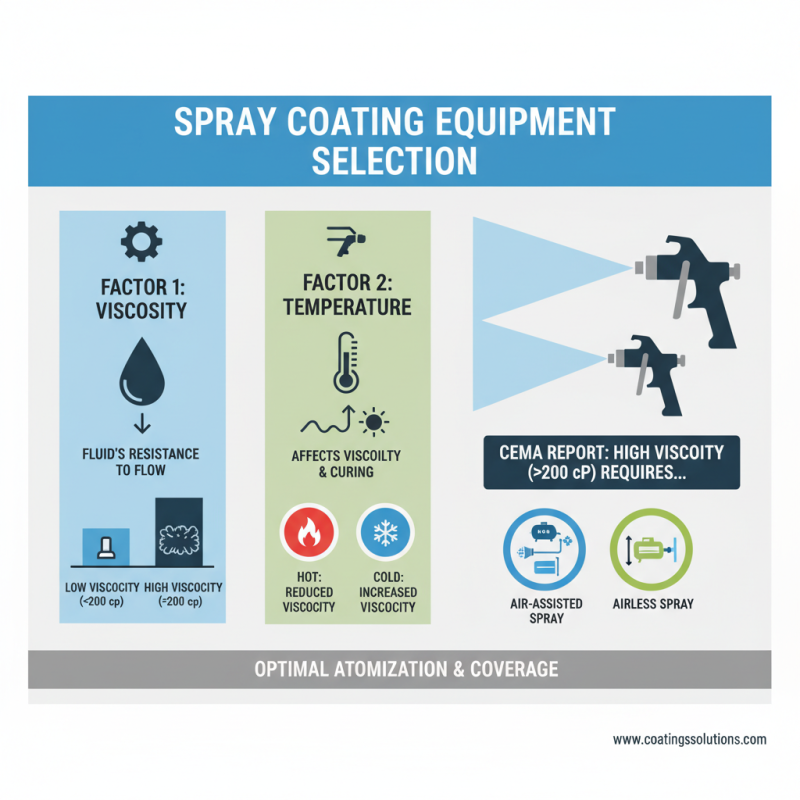

When selecting spray coating equipment, understanding application requirements is crucial. Two significant factors to consider are viscosity and temperature. Viscosity refers to a fluid's resistance to flow and is fundamental in determining the type of spray technology to be used. According to a report by the Coating Equipment Manufacturers Association (CEMA), thicker coatings with viscosities above 200 cP typically necessitate air-assisted or airless spray systems. These systems are designed to handle higher viscosity levels efficiently, ensuring optimal atomization and coverage during application.

Temperature significantly influences the performance of spray coatings as well. The performance characteristics of various coatings can change dramatically with temperature fluctuations. For instance, a study published in the Journal of Coatings Technology and Research indicates that many polyurethanes exhibit improved flow and leveling properties when applied at elevated temperatures, often between 70°F to 90°F (21°C to 32°C). By maintaining temperatures within this range, operators can avoid issues such as sagging or uneven coverage, leading to improved finish quality.

Additionally, surface conditions must be evaluated. Factors such as substrate porosity, texture, and cleanliness can affect coating adherence and finish quality. The American Coatings Association highlights that a properly prepared surface significantly enhances the bonding strength of the coating applied. Thus, ensuring that the application environment aligns with the specific requirements of viscosity and temperature is essential for achieving the desired results with any spray coating process.

When selecting spray coating equipment, understanding the differences between airless and air-assist spray systems is crucial for optimizing application efficiency and achieving desired finish quality. Airless spray systems utilize high pressure to atomize the coating material, which allows for a thicker application and higher transfer efficiency. According to industry reports, airless systems can achieve a transfer efficiency of up to 90%, making them ideal for heavy coatings and larger surfaces. This efficiency translates into reduced material waste and faster application times, a vital factor in high-volume environments.

On the other hand, air-assist spray systems combine compressed air with high-pressure fluid to create a finer atomization of the coating material. This results in a smoother finish and more control over the application, which is beneficial for detailed work. A study conducted by the Coatings Research Group indicates that air-assist systems can provide superior surface finishes, making them preferable for applications requiring high aesthetic quality. However, their transfer efficiency typically ranges from 60% to 80%, which can lead to greater material use compared to airless systems. Ultimately, the choice between these two systems should be guided by specific application requirements, including the type of coating, surface area, and desired finish quality.

| Feature | Airless Spray System | Air-Assist Spray System |

|---|---|---|

| Application Versatility | High | Medium |

| Finish Quality | Good | Excellent |

| Material Waste | Higher | Lower |

| Setup Time | Short | Longer |

| Cost | Lower Initial Investment | Higher Initial Investment |

| User Skill Level Required | Moderate | Higher |

| Ideal Applications | Rough Surfaces, Large Areas | Fine Finishes, Detail Work |

When selecting spray coating equipment, understanding industry standards and compliance is crucial. The standards defined by organizations such as ASTM International and the Environmental Protection Agency (EPA) provide guidelines to ensure safety and effectiveness in spray coating applications. For instance, ASTM D3960 outlines methods for determining volatile organic compound (VOC) emissions, a key concern in achieving environmental compliance. Reports indicate that improper management of VOC emissions can lead to penalties and operational inefficiencies, highlighting the necessity of equipment that meets these standards.

Moreover, compliance with ISO 9001 is becoming increasingly important in the spray coating industry, as it sets out the criteria for quality management systems. Companies adhering to ISO standards often experience improved operational efficiency and customer satisfaction. According to a study by the International Organization for Standardization, organizations that implement ISO 9001 see a 4.5% increase in productivity on average. Therefore, when choosing spray coating equipment, it is vital to ensure it aligns with these standards to enhance quality, reduce waste, and ensure overall compliance with regulatory requirements. This strategic focus not only safeguards the environment but also strengthens the integrity and reliability of the final coating product.