Choosing the right Metal Cutting Machine can seem overwhelming. Many options are available, each with unique features. Your specific needs should guide your decision.

Consider the type of materials you will cut. Different machines excel in cutting different metals. For instance, some are perfect for thin sheets, while others handle thicker steel. It's essential to research each option to identify what suits you best.

Remember, the price often reflects the quality. A low-cost Metal Cutting Machine may lack durability. It might require frequent repairs, impacting your productivity. Reflecting on your current and future needs can help avoid costly mistakes. Choosing wisely now saves you time and money later.

When selecting a metal cutting machine, understanding specific needs is crucial. Different applications require distinct capabilities. For instance, precise cuts for aerospace components demand high accuracy. According to a recent industry report, approximately 30% of companies struggle to find suitable machines for specialized tasks. This highlights the importance of aligning machine features with business requirements.

Material thickness is another critical factor. A report from the Metal Fabrication Association indicates that 70% of metalworking businesses deal with varying thicknesses in their projects. Operators must consider if the machine can handle the material type and thickness they typically encounter. Misalignment here can lead to inefficiencies and increased costs.

Additionally, consider production volume. Machines suited for high-volume production may not be ideal for smaller runs. This mismatch often leads to wasted resources. An estimated 20% of manufacturers report equipment underutilization due to purchasing decisions that did not reflect their operational realities. Analyzing these factors is essential to avoid future regret.

| Machine Type | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Best Material Type | Applications |

|---|---|---|---|---|

| Laser Cutting Machine | 20 | 20 | Stainless Steel | Signage, Precision Components |

| Plasma Cutting Machine | 30 | 15 | Mild Steel | Heavy Fabrication, Automotive |

| Waterjet Cutting Machine | 100 | 3 | Ceramic, Glass | Aerospace, Artistic Designs |

| Band Saw | 50 | 10 | Aluminum | General Fabrication, Construction |

| CNC Milling Machine | 20 | 5 | Alloys | Precision Parts, Aerospace Components |

When looking for a metal cutting machine, understanding the types available is essential. Various machines cater to different materials and applications. Common types include band saws, plasma cutters, and laser cutting machines. Each machine has its strengths and drawbacks. For example, plasma cutters are fast and efficient but may leave rough edges.

Consider your specific needs before making a choice. Think about the thickness and type of metal you will be cutting. Band saws are great for thicker materials, while laser cutters excel with precision. Remember, a more expensive machine doesn't always mean it's better for your tasks.

Tips: Test the machine if possible. This helps gauge its performance and usability. Also, consider after-sales service. A reliable service team can be a deciding factor when a machine faces issues. Join forums or user groups for personal insights. Engaging with experienced users can reveal hidden challenges. Keep an open mind about your needs as projects evolve. Your initial choice may require adjustments later on.

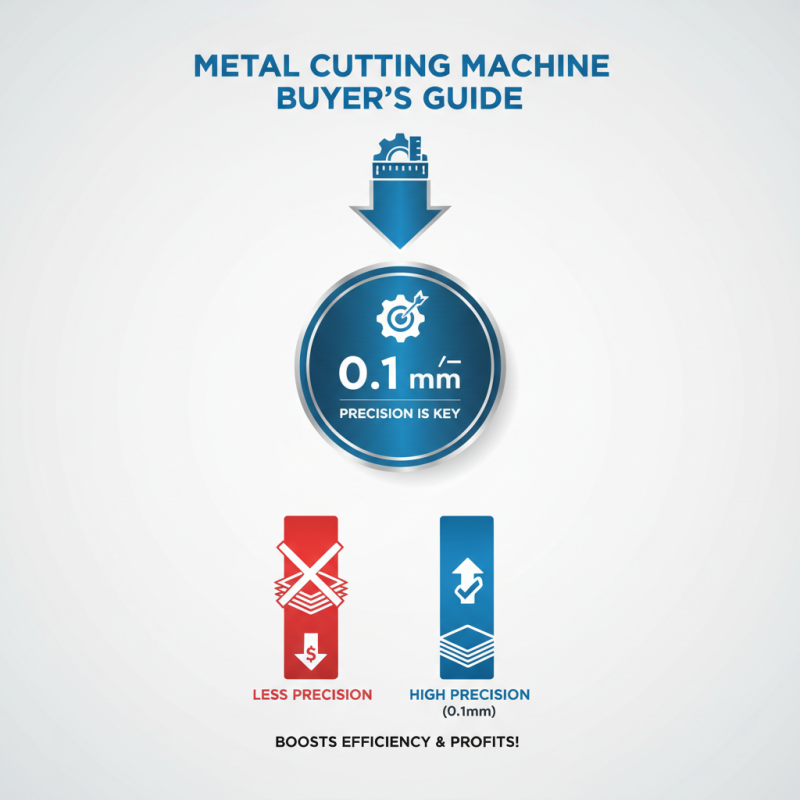

When selecting a metal cutting machine, understanding key features is crucial. Precision is paramount. Accurate cuts reduce waste and ensure quality. According to industry reports, machines with a precision rate of 0.1 mm can significantly improve overall production efficiency. This precision impacts your bottom line.

Power settings also play a critical role. A machine with adjustable power settings allows flexibility for different materials. For instance, cutting aluminum requires less power than steel. Having this versatility can save time and energy. Some studies suggest that machines with variable speed controls can enhance cutting performance by up to 30%.

Additionally, consider the machine’s ease of use and safety features. Complex controls can lead to mistakes, which is risky. Safety features like automatic shut-off are essential. Reports indicate that over 20% of machine accidents result from user error. Evaluating these aspects helps ensure a better fit for your specific needs. Balancing features with usability can be a challenge but is necessary for effective operations.

When selecting a metal cutting machine, budget is crucial. Industry reports indicate machinery can vary significantly in price. For instance, a basic machine might cost around $5,000, while advanced models can exceed $100,000. Understanding your specific needs helps in selecting cost-effective solutions.

Tips: Always assess your production requirements first. A high-end machine might not be necessary for low-volume tasks. Consider potential operational costs, including maintenance and consumables, which can add to the initial investment.

Cost-effectiveness doesn't solely hinge on initial price. A cheaper machine may lead to greater long-term expenses due to lower efficiency or durability. Reports suggest that well-invested machines can increase productivity by 30% or more. Therefore, evaluate your total cost of ownership over time.

Tips: Explore financing options. Leasing might offer flexibility if upfront costs are high. Don’t overlook the importance of training. Inadequate skills can waste resources, negating any savings from selecting a lower-cost option.

This bar chart illustrates the cost of different categories of metal cutting machines, helping prospective buyers to evaluate their budget and make an informed decision based on their needs.

When selecting a metal cutting machine, maintenance and support play a crucial role in its longevity. Regular cleaning and lubrication can prevent premature wear. Dust and debris can accumulate, impacting performance. After every few cuts, ensure that the machine is free of any buildup. This simple act can save you costly repairs down the line.

Additionally, consider the availability of technical support. Reliable assistance can make a significant difference during equipment issues. A local service team speeds up repairs. If the machine suffers from malfunction, having accessible support reduces downtime. In many cases, online resources may not suffice. Look for machines that offer comprehensive manuals.

Reflect on your maintenance routine. Are you dedicating enough time? A neglected machine can lead to frustrations and lost projects. Regular checks can help identify issues before they escalate. Embracing a proactive maintenance approach ensures optimal performance and enhances longevity. It's worth it to develop habits that fortify your machine's resilience.