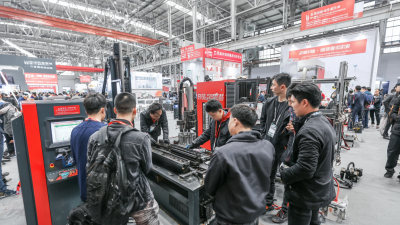

Choosing the right Glass Coating Equipment is crucial for achieving optimal results. As technology evolves, the options available are constantly changing. In 2026, selecting the best equipment will require understanding specific needs.

Different industries have varied applications for glass coating. For example, automotive glass, architectural glass, and even eyewear all demand unique features. One must consider factors like durability and ease of use. A well-informed decision can prevent future frustrations.

As you analyze various options, reflect on your specific requirements. Do you need high volume production or something more specialized? Remember, not all Glass Coating Equipment is created equal. Some might offer advanced features, but they may not be right for you. Balancing quality and cost will be crucial.

As the glass coating equipment market evolves, understanding its trends is crucial for making informed decisions. In 2026, innovations are expected to reshape the industry. Advanced technologies, like automated systems, will enhance efficiency. There might be a shift toward eco-friendly materials as sustainability gains importance. Companies will need to consider their environmental impact seriously.

However, the rapid pace of change can be overwhelming. Not all businesses keep up with new advancements. Some may still rely on outdated methods. This disconnect can hinder growth. Investing in modern equipment without adequate training can lead to issues. It's essential to balance innovation with practical application.

Market demand is another factor to reflect on. Customer preferences are shifting towards customization and quality. Businesses must adapt their offerings accordingly. Failure to recognize these changes may result in missed opportunities. Keeping an eye on competitor strategies can provide insights. Staying stagnant is not an option. Continuous improvement is vital for success in this dynamic market.

When considering high-performance glass coating machines for 2026, several key features stand out. First is the automation level. A machine that minimizes manual intervention can enhance efficiency. According to industry reports, automated systems can reduce production time by up to 30%. This efficiency directly translates to cost savings.

Another important feature is the adaptability of the coating technology. Machines capable of handling various substrates and coating types are more versatile. Flexibility can be a significant advantage in meeting diverse customer needs. Reports indicate that businesses with adaptable machines can accommodate up to 50% more product variations without significant downtime.

Additionally, innovative control systems are critical for precision. Machines equipped with advanced sensors offer better monitoring of coating thickness and uniformity. Ensuring consistent quality is crucial, especially in sectors like automotive and electronics. However, reliance on technology comes with challenges. Miscalibrations or software glitches can lead to significant production issues, impacting overall output. Understanding these limitations is vital for making informed equipment purchases.

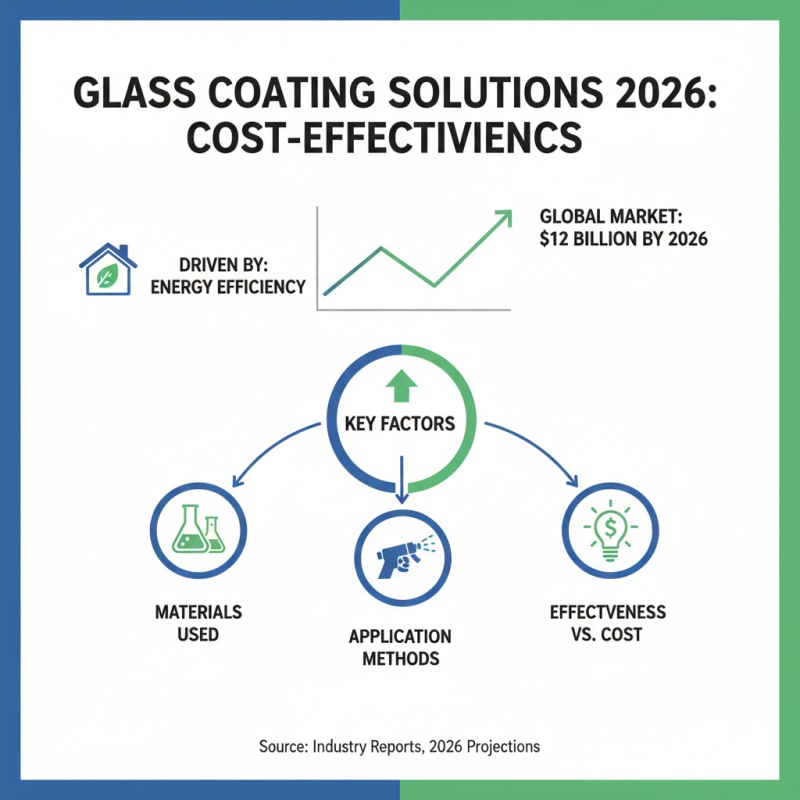

When evaluating the cost-effectiveness of glass coating solutions for 2026, companies face several critical factors. Industry reports suggest that the global glass coating market is expected to reach $12 billion by 2026. This growth is driven by increasing demand for energy-efficient solutions. Yet, effectiveness varies based on materials used and application methods.

Initial installation costs can be high. Some companies may hesitate to invest in advanced glass coating equipment. For instance, the average cost of high-quality equipment can exceed $200,000. While this is significant, the long-term savings in energy consumption can exceed 30%. It's essential to calculate the return on investment over several years. Potential clients should also consider maintenance costs. Regular upkeep can add an unexpected burden to budgets.

Companies often underestimate how differences in coating materials impact durability and performance. Not all coatings offer the same benefits, leading to mismatched expectations. A study indicates that over 40% of businesses using subpar coatings face premature failures. These failures result in additional costs and downtime. Practically, understanding the specific requirements of your projects is vital. This allows for smarter budgeting and better decision-making in the long run.

When selecting glass coating equipment, industry standards play a crucial role. Certifications can signify reliability and performance. In 2026, compliance with emerging standards will be essential. Look for equipment that meets ISO and other relevant certifications. These credentials indicate that the equipment has undergone rigorous testing.

Consider the materials used in the equipment’s construction. High-quality components can enhance performance and longevity. Sometimes, cheaper alternatives may seem appealing. However, they often lack necessary certifications. This might lead to failures or subpar performance down the line. It's wise to invest in reliable equipment, even if the initial costs are higher.

Review the manufacturer's history and their commitment to quality. Research shows that companies with a consistent track record in certifications tend to produce better equipment. Don’t hesitate to ask for documentation. Request evidence of compliance with current standards. An open conversation about certifications can reveal much about the product's potential reliability.

| Criteria | Description | Standard/Certification | Importance Level |

|---|---|---|---|

| Coating Uniformity | Ensures a consistent coating thickness across the surface. | ISO 12944 | High |

| Durability | Ability to withstand environmental factors and physical wear. | ASTM D 3359 | Critical |

| Application Compatibility | Effective with various types of glass and shapes. | ISO 8980 | Moderate |

| Environmental Impact | Assessment of VOC emissions and sustainability. | LEED certification | High |

| Efficiency | Production throughput and energy consumption. | ISO 50001 | Moderate |

| Safety Standards | Compliance with safety regulations for operators. | OSHA regulations | Critical |

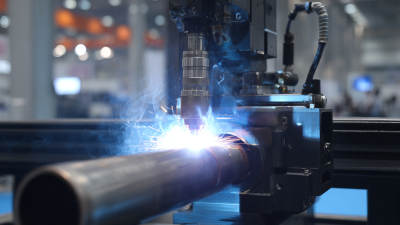

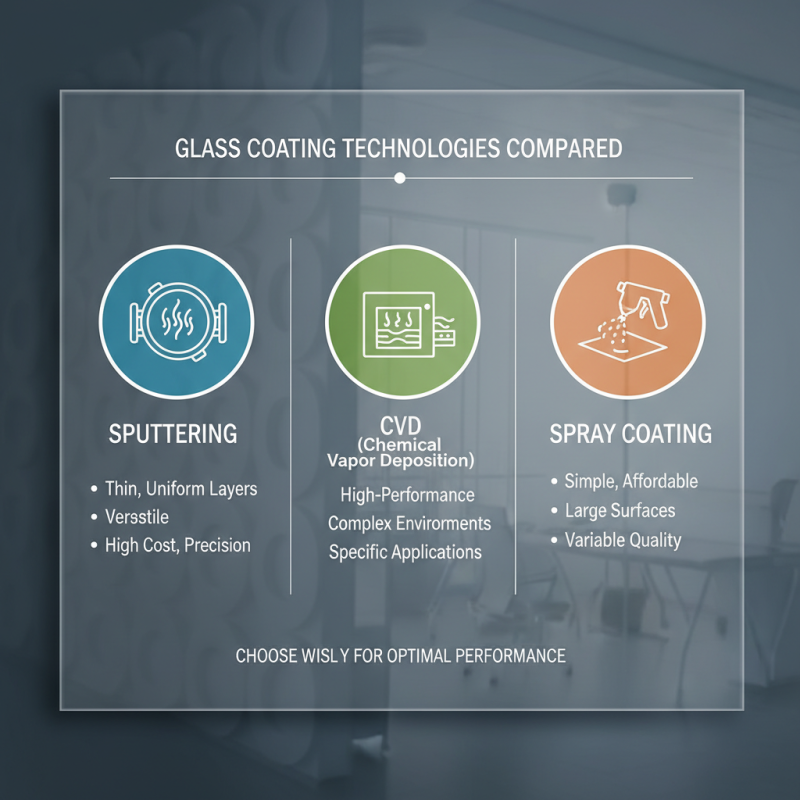

When selecting glass coating equipment, comparing technologies is vital. Different methods like sputtering, CVD, and spray coating offer distinct benefits. Sputtering produces thin, uniform layers, ideal for various applications. However, it requires precise control and can be costly. On the other hand, CVD is excellent for high-performance coatings but demands specific environmental conditions.

Each technology has its learning curve. Getting the right setup needs careful planning. Spray coating might seem easier, but achieving uniformity can be challenging. It is crucial to evaluate how these methods fit into your production workflow. Additionally, consider maintenance requirements and operational costs.

Brand reputation adds another layer to this decision. Some brands innovate rapidly, while others may lag behind. Examine user reviews and performance reports. Reflect on whether a newer technology might outshine established ones. Ultimately, weighing these factors will help you find equipment that aligns with your goals and needs.