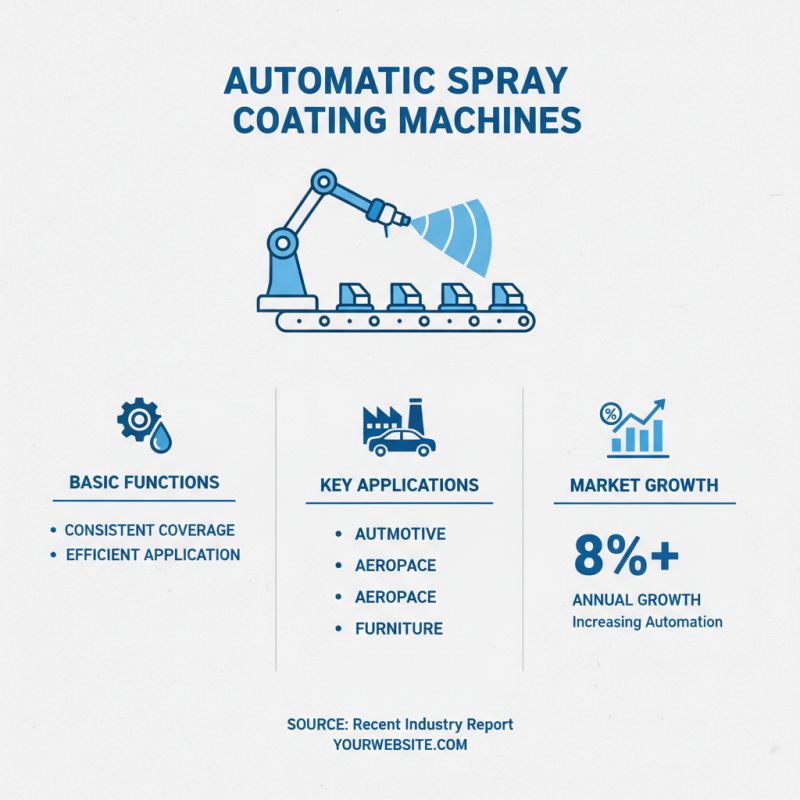

Choosing the right Automatic Spray Coating Machine can drastically affect your production quality. According to a recent market report, the global spray coating equipment market is projected to reach $5.3 billion by 2026, growing at a CAGR of 4.7%. This growth underscores the increasing demand for efficient coating solutions across various industries.

An Automatic Spray Coating Machine provides precision and consistency. Manufacturers are investing heavily in this technology to enhance their productivity. However, selecting the ideal machine isn't always straightforward. Factors such as the intended application, material types, and production volume must be considered.

Quality and efficiency should guide your choice. Some machines may promise high output but fail on durability. It’s crucial to reflect on your operational needs and future scalability. An appropriate investment today can yield significant returns tomorrow. In this evolving industry, the right Automatic Spray Coating Machine can be your key to staying competitive.

Choosing the right automatic spray coating machine involves understanding their basic functions and applications. These machines offer consistent and efficient coverage for various surfaces. They are used in industries like automotive, aerospace, and furniture manufacturing. According to a recent industry report, the global market for automatic spray coating machines is projected to grow by over 8% annually. This growth highlights the increasing reliance on automation in coating processes.

Automatic spray coating machines rely on advanced technology for precision. Many machines use electrostatic spraying, which enhances paint adhesion and reduces waste. This technology can improve transfer efficiency significantly. Some studies indicate that environments equipped with these machines can achieve more than 85% transfer efficiency compared to manual methods. However, the initial costs for these machines can be high, leading to hesitation among smaller manufacturers. They may also require skilled personnel for operation and maintenance.

Various factors should be assessed when choosing a spray coating machine. The type of materials being coated is crucial. Different machines handle different viscosities and chemical compositions. Compatibility issues can arise. Users must also consider production rates. A faster machine may increase output but also raise the risk of imperfections in the coating. Contemplating these factors is essential for making a sound investment.

Choosing the right automatic spray coating machine involves careful consideration of several key features. One important aspect is the machine's nozzle design. A well-designed nozzle ensures even application and minimizes wastage. Look for machines that offer adjustable spray patterns. This flexibility helps adapt to various surfaces and coating materials.

Another critical feature is the machine’s output capacity. A higher capacity allows for faster work, saving time on large projects. However, ensure that it does not compromise quality. Some machines promise speed but may lead to uneven coats. It's essential to strike a balance between efficiency and finish quality.

Don't overlook ease of maintenance. Machines with complicated parts can lead to downtime. A user-friendly design can simplify cleaning and upkeep tasks. Also, consider the machine's size and portability. If space is limited, a compact unit may suit your needs better. Research user reviews to see common issues. This can provide insights into performance and reliability. Keep these factors in mind for a more informed decision.

Choosing the right automatic spray coating machine can greatly impact your project's success. Assessing your project requirements is a vital first step. Consider the type of surfaces you will coat. Different machines work better on various materials. For instance, some machines excel on metals, while others are better for plastics. The size of your components will also affect your choice. Some machines can only handle small items, while others are designed for larger projects.

It is essential to think about your production volume as well. If you have a high turnover, you need a machine that operates efficiently. Speed and precision are crucial. A machine that is too slow will bottleneck your workflow. Additionally, evaluate the ease of maintenance and operation. This might seem minor now but can save time and frustration later. Machines that are difficult to clean or troubleshoot may require more downtime.

Lastly, reflect on your budget constraints. It might be tempting to opt for the cheapest option. However, a low-cost machine could lead to more problems down the line. Investing in quality may appear costly at first, but it often pays off. Balancing quality with cost is tricky. It may be necessary to prioritize some features while compromising on others. Each choice comes with trade-offs that warrant careful consideration.

This bar chart illustrates the importance of various selection criteria when choosing the best automatic spray coating machine for your project. Each criterion is scored on a scale from 1 to 10, highlighting the focus areas for optimal machine choice.

When selecting an automatic spray coating machine, performance and reliability are key. Different brands and models often showcase varied capabilities. Some machines excel in speed, while others may have a more consistent spray pattern. Look closely at user reviews. They often reveal strengths and flaws that specifications do not.

Testing multiple machines can provide firsthand insights. Some may disappoint in durability or have inconsistent results. Fine-tuning settings is sometimes necessary. This process can be frustrating but is vital for achieving the best finish. Be prepared for the trial and error involved in selecting the right model.

Consider additional features as well. Some machines offer digital controls for easier operation. Others might boast larger capacity but lack precision. Weighing these factors carefully helps. Performance can vary greatly among models, and you will want to avoid costly mistakes. Investing time in research and comparisons now can save future headaches.

Investing in an automatic spray coating machine requires careful consideration of cost versus value. A recent industry report indicates that businesses can save up to 30% on labor costs by adopting automated spray systems. This efficiency translates into a quicker return on investment. However, upfront costs may vary significantly. The initial investment might be daunting, often ranging from $10,000 to $100,000.

Companies should assess the long-term benefits of these machines. For instance, many automatic spray coating systems offer enhanced precision, leading to reduced material waste. This can save companies about 15% on material costs annually. Yet, not every machine suits every operation. Selecting the wrong machine can result in higher operational costs and increased downtime. A study highlighted that 25% of manufacturers regretted their equipment choices due to inadequate research.

While cheaper systems may seem appealing, they often compromise quality. A machine that fails to perform consistently may lead to reworks and delays. Investing more upfront can enhance durability and reliability. In machine selection, understanding specific needs is essential for aligning cost with potential value returns. The landscape is changing, and staying informed is key to making the right choice.

| Feature | Description | Cost (USD) | Value (1-10) |

|---|---|---|---|

| Spray Width | Adjustable spray width for different applications | 1500 | 8 |

| Operating Speed | Speed of coating application (meters/min) | 1200 | 7 |

| Power Consumption | Energy efficiency during operation | 300 | 9 |

| Maintenance Requirement | Frequency and cost of maintenance | 200 | 6 |

| User Interface | Ease of use and programming features | 400 | 8 |

| Warranty | Coverage and duration of warranty | N/A | 9 |