In today's competitive manufacturing landscape, selecting the right Metal Cutting Machine is pivotal for enhancing productivity and maintaining quality standards. According to a report by MarketsandMarkets, the global metal cutting market is projected to reach $220 billion by 2025, driven by increasing automation and demand for precision engineering. Choosing an appropriate cutting machine not only influences operational efficiency but also directly affects production costs and product quality. As businesses seek to optimize their manufacturing processes, understanding the specific requirements of their operations, including material types and production volumes, becomes crucial. This blog will explore the key factors that businesses must consider when investing in a Metal Cutting Machine to ensure they meet both current and future demands.

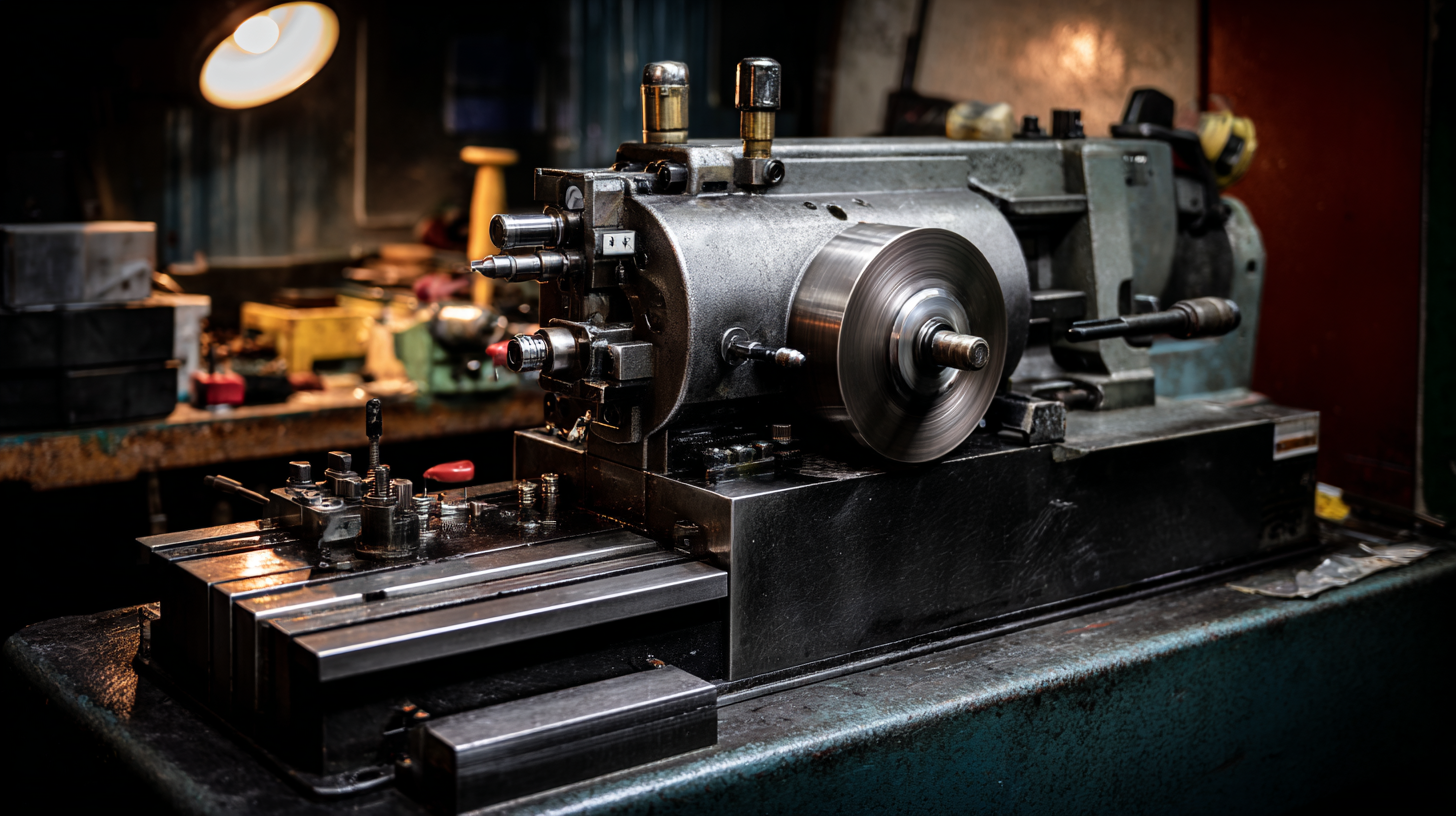

When selecting a metal cutting machine, understanding the different types available is crucial for aligning with specific business needs. Among the most common types are plasma cutting machines, laser cutting machines, and waterjet cutters. Plasma cutters are ideal for thick materials, offering quick and precise cuts, making them suitable for fabrication shops that require speed and efficiency. On the other hand, laser cutting machines excel in delivering high precision on thinner metals, favored in industries where intricate designs are necessary, such as automotive or aerospace.

Waterjet cutting machines provide a unique advantage, utilizing high-pressure water mixed with abrasive materials to cut through a range of materials without generating damaging heat. This method is particularly beneficial for industries that handle sensitive materials, such as metals with distinct thermal properties. Each metal cutting machine brings distinct benefits tailored to various applications, making it vital for businesses to carefully assess their specific requirements, production volume, and material types to make an informed choice that enhances operational efficiency.

This chart illustrates the effectiveness ratings of different metal cutting machines based on their common applications and benefits. Laser cutting and waterjet cutting show the highest effectiveness, while band sawing has the lowest, reflecting the varied applications in the metalworking industry.

When selecting a metal cutting machine for your business, evaluating both precision and speed is essential for achieving optimal performance. According to a recent report by the Global Metal Cutting Tools Market, precision metal cutting solutions have seen a 30% increase in demand over the past five years, driven by industries requiring highly accurate components.

Machines with high precision capabilities tend to feature advanced CNC technology, which allows for tighter tolerances and better repeatability. For instance, laser cutting machines are known to achieve accuracy levels of ±0.01 mm, making them ideal for intricate designs and detailed work.

Speed is another critical factor in choosing the right metal cutting machine. The same market analysis highlights that machines capable of operating at higher speeds can significantly enhance production efficiency, with some advanced plasma cutters achieving cutting speeds of up to 20 meters per minute without sacrificing quality. Furthermore, investing in a machine that offers quick tool changes and setup times can dramatically reduce downtime, contributing to increased throughput and ultimately a stronger bottom line.

Balancing these two parameters—precision and speed—will help businesses not only meet current demands but also adapt to future market challenges.

When selecting a metal cutting machine, it’s essential to evaluate both your budget constraints and the long-term investment value. A well-planned budget not only covers the initial purchase cost but also accounts for maintenance, operational efficiency, and potential upgrades. Investing in a quality machine may require a higher upfront expenditure but often leads to greater savings over time due to reduced downtime and better performance.

**Tips:** Consider conducting a cost-benefit analysis, weighing the machine's price against its expected lifespan and operational cost. Look for models that offer energy efficiency, as this can significantly lower your bills in the long run.

Additionally, think about the scalability of the equipment. As your business grows, your cutting needs may evolve. Focusing on machines that are compatible with various technologies or allow easy upgrades can enhance their value as long-term investments.

**Tips:** Research manufacturers that provide excellent customer support and warranties, ensuring peace of mind in case of future issues. Having a machine that can grow with your business can be a game-changer in staying competitive in the metal cutting industry.

In today's competitive landscape, staying ahead means investing in the latest metal cutting technologies that boost efficiency. Innovations such as laser cutting, waterjet cutting, and plasma cutting have transformed how metal components are manufactured. These advanced methods not only enhance precision but also significantly reduce waste, allowing businesses to maximize their production capabilities and minimize cost.

The rise of automation and smart technologies in metal cutting machines further amplifies efficiency. Machines equipped with artificial intelligence and machine learning algorithms can predict maintenance needs, optimize cutting paths, and even adjust settings in real-time based on material properties. This level of sophistication not only ensures high-quality outputs but also streamlines operations, decreasing the manual labor required and allowing for swift adjustments to varying production demands. As companies embrace these cutting-edge technologies, they find themselves better equipped to tackle complex projects and meet the increasing demands of their clients more effectively.

As industries increasingly adopt advanced digital manufacturing technologies, the demand for specialized metal cutting solutions continues to rise. Companies are now prioritizing high precision and efficiency, making it essential for them to select machines that not only meet their production needs but also align with sustainability goals. Environmentally friendly machines with lower operation costs are becoming pivotal, enabling a shift from traditional processes to automated systems, which enhance overall productivity.

The industrial knife market, valued at $450 million in 2022, is projected to reach $680 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. Concurrently, rising material costs pose challenges for the cutting tool inserts market, impacting the production of high-tech materials such as cubic boron nitride and polycrystalline diamond. Thus, manufacturers must navigate these trends and challenges carefully.

By focusing on innovation and efficiency, businesses can position themselves competitively within the evolving landscape of metal cutting technologies.