Choosing the right Welding Ultrasonic Machine is crucial for ensuring efficiency and precision in your production process. The market offers various models, each catering to different needs. With so many options, it can be overwhelming to make a choice. You may wonder how to assess your specific requirements effectively.

When selecting a Welding Ultrasonic Machine, consider factors such as power, frequency, and application type. Power affects the speed and energy of the welding process. Frequency impacts the quality of the weld. In addition, you should reflect on what materials you will be working with. Different machines perform better with specific materials.

It can be easy to overlook maintenance needs when choosing a machine. A well-maintained Welding Ultrasonic Machine ensures longevity and consistent performance. Researching user experiences may reveal insights you hadn’t considered. Don’t rush into a decision; weight your options carefully. Take time to evaluate your choices based on practical application. Ultimately, your choice will influence your production efficiency.

Ultrasonic welding technology is a powerful method used to join plastic or metal parts. It employs high-frequency ultrasonic vibrations to create a melting point in the materials being joined. This process is quick and energy-efficient. The machine uses a transducer that converts electrical energy into mechanical vibrations. These vibrations are then directed into the materials.

Understanding the specifications is crucial. Factors such as power output, frequency, and type of tooling can dramatically influence performance. A machine with higher power output is beneficial for thicker materials. However, this may lead to overheating issues if not monitored closely. It’s essential to strike a balance between power and the material properties.

While ultrasonic welding offers many advantages, it’s not foolproof. Some materials may not weld effectively, leading to weak joints. Initial tests are often necessary to determine compatibility. It’s important to reflect on the limitations of the technology. An informed choice can prevent costly production errors. Continuous learning and adaptation are key in optimizing the welding process.

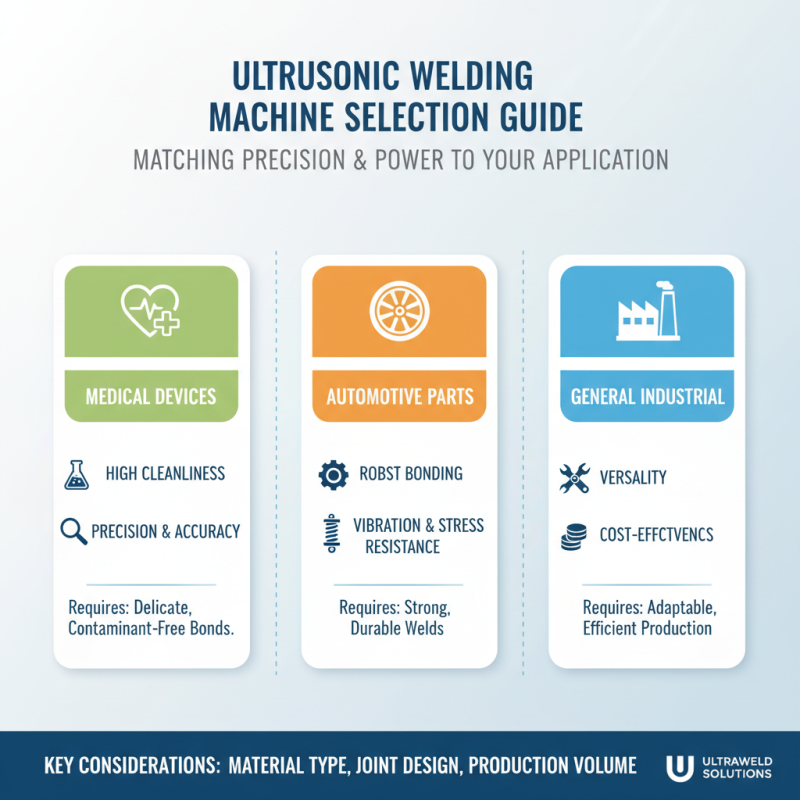

When selecting an ultrasonic welding machine, identify your specific needs and applications. Different projects require varying levels of precision. For instance, medical devices often necessitate high cleanliness and accuracy. Likewise, automotive parts might need robust bonding due to vibration and stress. Each application has its criteria.

Consider the materials you’ll be working with. Some machines perform better with plastics, while others can handle metals. Look at the thickness and type of material. You may need a machine able to adapt to diverse thicknesses. Think about your production volume as well. High-demand environments require machines that operate efficiently and consistently.

Don’t forget about future needs. Your business may grow and diversify. A flexible machine can save you time and money down the road. Reflect on your current limitations. Are there features you wish you had? Focus on machinery that offers scalability. Ultimately, understanding your unique requirements is essential for making the right choice.

When evaluating ultrasonic welding machines, key features play a vital role. Frequency is one significant aspect to consider. Most machines operate around 20 kHz to 40 kHz. A higher frequency can lead to finer welds. However, lower frequencies can offer more robust and deeper penetrations. According to industry research, optimal frequency settings can improve production rates by up to 30%.

Another crucial feature is power output. Machines typically range from 500 watts to over 3000 watts. Higher wattage machines often weld thicker materials. This means businesses must reflect on their material types and thickness. Reports indicate that nearly 40% of manufacturers fail to fully utilize their machine's power capabilities. They may end up under- or over-welding, impacting production quality.

Ease of operation is also important. Advanced machines have user-friendly interfaces and programmable settings. However, many operators still struggle to adapt. Research suggests that up to 25% of machine downtime is due to operator errors. Familiarization with the equipment is essential for efficiency. Continuous training can mitigate such issues, ensuring better use of features and reducing wastage.

| Feature | Description | Importance Level | Typical Range |

|---|---|---|---|

| Frequency | Operating frequency of the ultrasonic machine | High | 20 kHz - 40 kHz |

| Power Output | Power available for welding applications | High | 100 W - 3000 W |

| Welding Time | Duration for which ultrasonic energy is applied | Medium | 0.1 s - 5 s |

| Ease of Use | User-friendly interface and controls | High | N/A |

| Size and Portability | Dimensions and weight of the machine | Medium | 15 kg - 50 kg |

| Material Compatibility | Types of materials that can be welded | High | Plastics, Metals, Composites |

| Cost | Price range of the ultrasonic welding machine | High | $1,000 - $20,000 |

When selecting an ultrasonic welding machine, a thorough comparison of manufacturers and models is crucial. Various reports indicate that the market for ultrasonic welding equipment has grown significantly, with a compound annual growth rate (CAGR) of around 7% projected through 2025. This growth implies that companies are investing more in advanced technology.

Different manufacturers offer diverse specifications. For instance, frequency ranges can greatly affect performance. Many models operate within 20 kHz to 40 kHz. A variety of applications also requires different power settings. Some require high power for thick materials, while others may need lower power for delicate assemblies.

Tips: Before placing an order, demo the machine if possible. Evaluate sample welds for consistency, strength, and quality. Also, check the technical support offered by the manufacturer. Good customer service can be essential for troubleshooting.

It's also vital to consider the long-term value. Some cheaper models might not come with robust warranties. Regular maintenance can be an added cost, which manufacturers sometimes don’t disclose upfront. Reflecting on these factors can shape your ultimate choice and ensure you invest wisely.

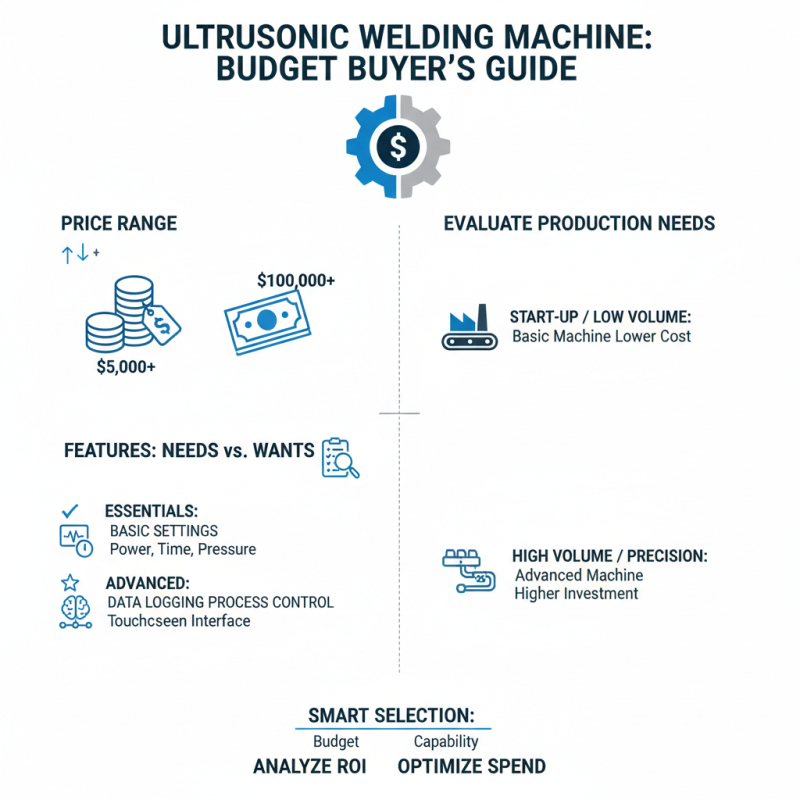

When selecting an ultrasonic welding machine, budget constraints matter. The price range can vary widely. Understand what features you need versus what you can live without. Evaluate if basic settings meet your production needs or if advanced functions are essential.

Tips: Assess your current workflow. Identify any inefficiencies. A simpler machine might save costs while meeting requirements. Extra features often come with increased prices. Balance between necessity and luxury.

Also, consider long-term costs. Lower-priced machines may save money upfront but could incur high maintenance costs. Check user reviews to gauge performance and reliability. Sometimes, investing a bit more initially pays off over time. Use this investment wisely to avoid regrets later. Focus on the machine's lifespan as well.