In the medical device industry, selecting the right Stent Coating Machine is crucial. According to the latest report by Market Research Future, the global stent market is expected to reach $12 billion by 2027. A stent coating machine plays a vital role in ensuring stents meet safety and efficacy standards. Experts believe that precise coating processes can significantly enhance device performance.

Dr. John Smith, a leading authority in the field, once stated, "The efficiency of a stent coating machine directly impacts patient outcomes." This underscores the importance of choosing the right equipment for your needs. Factors to consider include coating uniformity, machine speed, and compatibility with various stent materials.

Investing in subpar machinery can lead to poor results. Manufacturers often overlook critical features like software integration and maintenance costs. Such oversights can compromise both production and product quality. Therefore, it's essential to evaluate your specific requirements thoroughly before making a decision on a Stent Coating Machine. Making the right choice can redefine success in stent production.

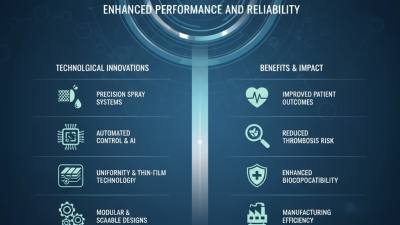

Choosing the right stent coating machine is crucial for medical device manufacturers. Several factors influence this decision. The coating technology used is one of the most important. For instance, drug-eluting stents require precise application to ensure effective drug delivery. Studies show that uniform coating thickness impacts performance and biocompatibility.

Next, consider the machine's automation level. Fully automated systems enhance consistency, reducing human error. According to industry reports, automated processes can improve production efficiency by up to 40%. However, this can lead to higher initial investments. Remember to evaluate your budget versus the potential long-term savings.

Tips: Assess the scalability of the machine. Will it adapt to future needs? Also, examine the ease of maintenance. A complex system may lead to increased downtime. Look for machines that offer user-friendly interfaces with straightforward maintenance protocols.

Lastly, pay attention to customer support and training. Proper training ensures operators fully understand the system's capabilities. Investing in a machine without support can lead to costly mistakes. Keep these factors in mind for effective decision-making.

| Feature | Importance Level | Recommended Value | Notes |

|---|---|---|---|

| Coating Uniformity | High | ≥ 95% | Ensures consistent performance and safety. |

| Production Speed | Medium | 300-500 stents/hour | Balance efficiency with quality. |

| User Interface | High | Intuitive and easy to navigate | Streamlines training and operation. |

| Flexibility | Medium | Multiple coating options | Adapt to various stent designs. |

| Maintenance Requirements | High | Easy and low cost | Critical for long-term operations. |

Stent production employs various coating technologies. Each type has unique features and benefits. Understanding these can help choose the right stent coating machine.

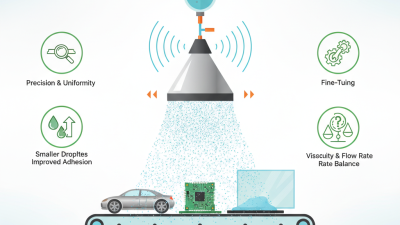

One common method is dip coating. It's relatively simple and cost-effective. This technique involves immersing the stent in a liquid coating solution. Data shows that dip coating can provide uniform thickness. However, achieving precise control over the coating layer remains a challenge. Variability in results can lead to inconsistent performance.

Another popular option is spraying. Spray coating allows for better control over coating parameters. This can lead to customized solutions for different stent types. According to recent reports, this method can reduce production waste significantly. Yet, it requires advanced machinery and skilled operators. Ensuring consistency with spray coating can also be difficult. These factors make it important to evaluate your specific needs.

Choosing the right stent coating machine involves careful evaluation of performance and efficiency. Several aspects come into play here. Look at the machine's speed. A faster machine can increase productivity. However, speed shouldn't come at the cost of quality. It's crucial to find a balance between these two factors.

Next, focus on precision. The coating thickness must meet strict standards. If it varies too much, it can lead to product failures. A machine with advanced control systems can help in achieving uniform coatings. You might want to test samples to ensure consistency.

Consider energy consumption too. Efficient machines save costs in the long run. Yet, some machines may show promising specs but underperform in real-world scenarios. It's important to gather user feedback. Real experiences can shed light on the machine's actual capabilities and any potential flaws.

When investing in stent coating equipment, understanding its maintenance and support is crucial. Manufacturers report that nearly 30% of stent production disruptions stem from equipment failure. Regular maintenance can mitigate this. Having a reliable maintenance schedule helps ensure machinery operates efficiently.

Daily checks can spot wear and tear. Operators should perform routine tasks like cleaning and lubrication. Regular calibration ensures precision in coating applications, reducing waste. A report found that machines with ongoing support had 15% lower operational costs.

Choosing equipment with solid after-sales support is essential. Organizations that invest in training see 25% fewer operational issues. User-friendly manuals and access to expert help make a significant difference. Nonetheless, not every provider meets these needs effectively. It’s vital to research customer experiences before making decisions.

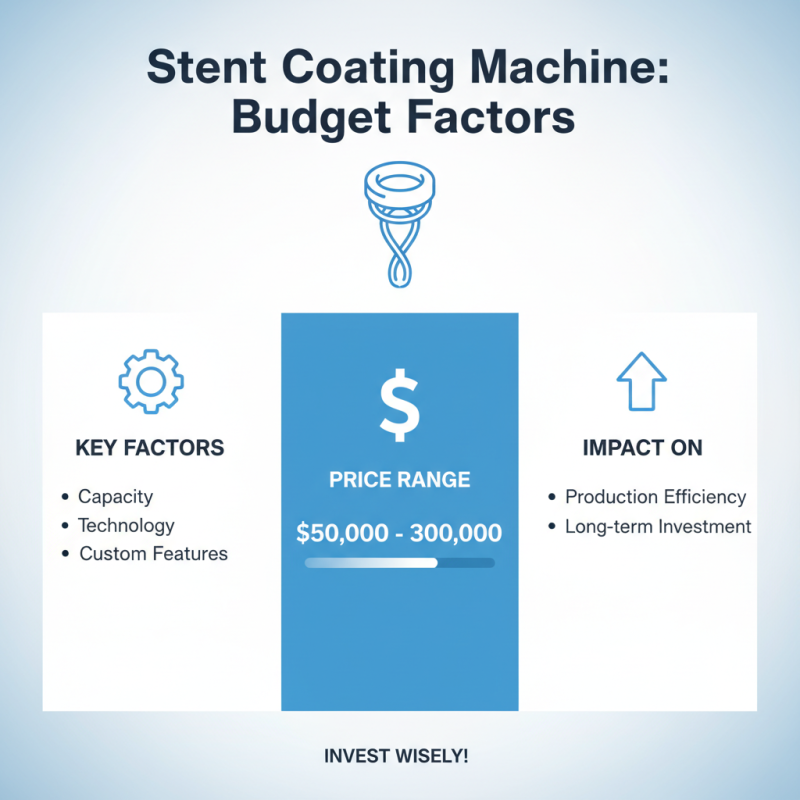

When considering a stent coating machine, budget is a key factor. The costs can vary significantly based on specifications. Prices typically range from $50,000 to $300,000. Factors influencing the budget include the machine’s capacity, technology, and custom features. Investing wisely can impact overall production efficiency.

Tip: Research industry reports on stent coating machine trends. These reports indicate that a machine’s lifespan often exceeds ten years, making it crucial to choose wisely. Avoid the cheapest options; they may compromise quality.

Consider the total cost of ownership. This includes operating expenses, maintenance, and potential downtime costs. A machine that is cheaper upfront may result in high operation costs later. Investing a bit more initially can lead to better long-term savings.

Tip: Look for machines with lower energy consumption rates. Studies show that energy-efficient machines can reduce costs by up to 20%. Balance your budget with the potential for efficiency. Always reflect on the long-term implications of your purchase decisions.