Choosing the right Industrial Coating Machine can be a daunting task. Your business's success depends on it. An effective coating process boosts productivity and enhances product durability. Understanding your specific needs is essential.

This guide delves into various options. Factors like machine size, features, and application types will be discussed. Some businesses may overlook their unique requirements. Choosing a machine that fits your needs is crucial. Not every Industrial Coating Machine serves all industries effectively.

Consider how different machines perform in real-world settings. Seek recommendations and user reviews. Reflection on your operational goals is vital. Industrial coating is not just about coatings; it’s about longevity and quality. Finding a machine that balances cost and performance is challenging. Let's explore your options.

When choosing the right type of industrial coating machine for your business, it's essential to assess your specific needs. Different industries require various coating processes. For example, automotive parts often need superior durability, while electronics might focus on insulation and heat resistance. Evaluate your materials and the environment in which you’ll use the coated items.

Tips: Identify the coating thickness required. It varies by application. Consider machines that offer adjustable settings. This flexibility may be crucial for diverse projects. Also, think about the machine's maintenance. Some devices require frequent upkeep, impacting productivity.

Pay attention to the automation level. Automated machines can increase efficiency and reduce human error. However, they may come with a steep learning curve. In contrast, semi-automated machines might be more user-friendly but fall short in speed and repeatability. Choose wisely based on your team's expertise and training capacity.

When selecting an industrial coating machine, several key features must be evaluated for optimal performance. One of the primary considerations is the machine's application versatility. According to a recent industry report, around 65% of businesses require machines that can handle various materials, such as metals, plastics, and composites. This flexibility can greatly influence operational efficiency, especially in industries that demand quick changes in production lines.

Another important factor is the machine's coating quality and consistency. Inconsistent coating can lead to costly reworks and affect product durability. Studies indicate that machines with advanced spray technology achieve up to 90% transfer efficiency, compared to older models that may only reach 50%. Additionally, having a reliable control system allows for precision in thickness and finish quality. It’s worth noting that some newer machines may require additional training, which could initially slow down production.

Energy consumption is also vital. An efficient machine can reduce operational costs significantly. Reports reveal that energy-efficient models can save up to 30% on operating costs. However, initial investment costs may be higher, leading companies to question their return on investment. Businesses must weigh these advantages against potential downsides. Balancing immediate budget constraints with long-term benefits is a challenge many face. This reflection can guide stakeholders in making better-informed decisions about their equipment choices.

When choosing an industrial coating machine, it's essential to consider various options available on the market. Different machines come with unique features and capabilities. Some machines are designed for high-speed operations, while others focus on precision and detail. Depending on your business needs, one machine may outperform another in specific applications.

Price points also vary significantly. Some machines cater to budget-conscious businesses, while others are geared towards those looking for advanced technology. Not all expensive machines guarantee quality. It’s wise to evaluate features against cost to ensure you're making the right investment. Reviews from industry peers can provide insight but remember, every facility is unique.

Maintenance is another critical aspect to consider. Some machines require more upkeep than others. Regular maintenance can prevent breakdowns, but not every model makes this easy. It’s vital to research how often maintenance is needed and what that entails. Not understanding these details can lead to unexpected costs down the line. Choose wisely.

Maintaining your industrial coating machine is essential for optimal performance. Regular cleaning is a must. Residue buildup can affect application quality. Make a routine schedule to clean the machine after each use. This simple task can prevent costly repairs.

Check the components regularly. Worn-out parts can lead to inefficiencies. Replace any damaged seals or hoses immediately. Ignoring them might cause leaks or even machine failure. Lubrication is also crucial. Ensure moving parts are adequately lubricated to prevent friction damage.

Don’t forget about the calibration. Machines can drift over time. Periodically, you should test and adjust settings to maintain precision. This step can save time and materials in the long run. It’s easy to overlook, but neglecting calibration may result in compromised coating quality. Stay proactive in your maintenance efforts for better longevity and performance.

| Machine Type | Application Area | Max Coating Thickness (microns) | Average Maintenance Cost (USD/year) | Expected Lifespan (years) |

|---|---|---|---|---|

| Electrostatic Spray Gun | Metal Surfaces | 80 | 1500 | 10 |

| Powder Coating Machine | Various Surfaces | 250 | 2000 | 12 |

| Automatic Spraying Machine | Large Scale | 100 | 2500 | 15 |

| Ultrasonic Coating Machine | Electronics | 50 | 1000 | 8 |

| HVLP Spray Gun | Furniture | 70 | 1200 | 9 |

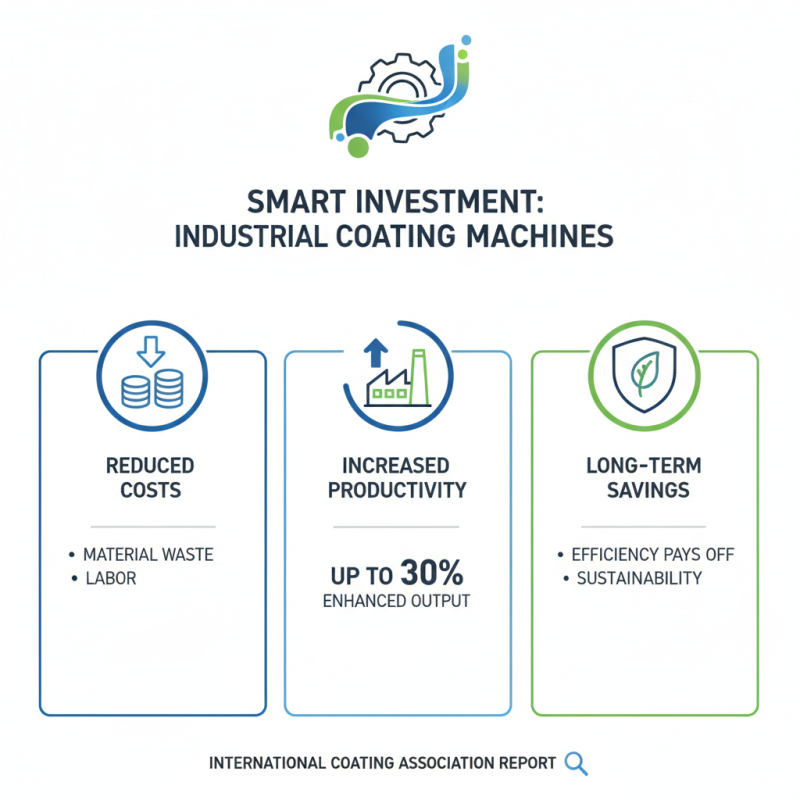

When evaluating industrial coating machines, cost-effectiveness is crucial. According to a recent report by the International Coating Association, companies often overlook the long-term savings these machines can provide. Investing in an efficient coating system can lead to reduced material waste and lower labor costs. In fact, the right machine can enhance productivity by up to 30%.

Tip: Assess your production volume before selecting a machine. Understand your specific needs. A machine suited for a small workshop might not be ideal for a larger facility.

Consider runtime efficiency and maintenance costs in your analysis. Data shows that downtime can negate savings, making reliability essential. Expensive machinery may seem tempting, but if it breaks down often, costs can escalate quickly. Some machines may have lower upfront costs but higher operational costs.

Tip: Seek feedback from industry experts. Their insights can highlight the real-world performance of different machines. Remember that every business has unique needs. Tailor your investment to your specific situation.