In 2026, the selection of fuel nozzles has become crucial for efficiency and safety. Choosing the right fuel nozzle can significantly impact your fueling experience and vehicle performance. Many factors warrant attention, including design, durability, and ease of use.

Fuel nozzles come in various styles and materials, each suited for different needs. Some are designed for heavy-duty use, while others target everyday consumers. Users often overlook the importance of weight and grip. A nozzle that feels heavy can be cumbersome over time.

In summary, understanding your options is essential. Mistakes in selection can lead to inefficiencies, wasting time and fuel. Taking the time to choose the right fuel nozzle will pay off. Don't rush the decision; consider the details and how they affect your daily routine. Make informed choices for a better fueling experience.

In 2026, fuel nozzle technology has evolved significantly. These devices now feature advanced materials that enhance durability and efficiency. Many nozzles are lightweight yet strong, allowing easier handling for users. The design has also improved, focusing on ergonomics and user comfort.

Through this innovation, many issues have surfaced. Some nozzles still struggle with leakage under pressure. This problem can lead to wasted fuel, raising environmental concerns. Manufacturers are trying to address these leaks, but progress is slow. The challenge is finding a balance between technology and cost-effectiveness.

Additionally, the integration of smart technology is becoming more common. Some nozzles now have sensors that monitor fuel flow. These sensors can provide real-time data for better efficiency. However, the complexity of these systems can lead to maintenance challenges. Users need to stay aware of potential issues to ensure optimal performance.

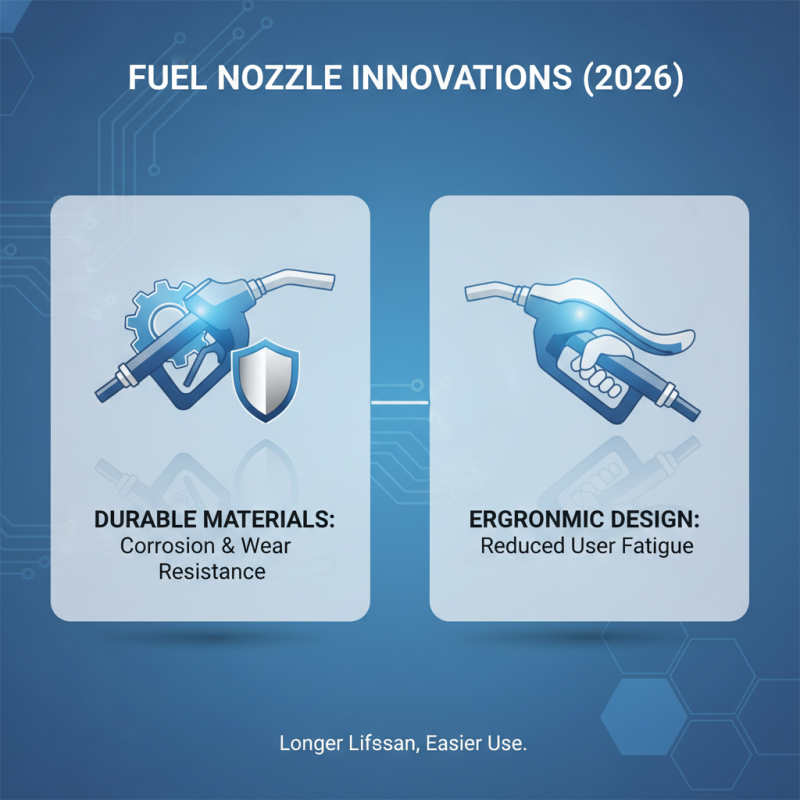

When considering fuel nozzles in 2026, there are several key features to examine. Material quality is crucial. High-grade materials resist corrosion and wear. This prolongs the nozzle's lifespan. Additionally, ergonomic designs enhance ease of use. A comfortable grip helps reduce user fatigue during refueling.

Flow rate is another significant aspect. Nozzles with adjustable flow rates cater to various vehicles. This flexibility ensures efficient refueling, whether for small cars or larger machinery. Look for nozzles equipped with automatic shut-off mechanisms. These systems prevent spills, promoting safer refueling practices.

Lastly, focus on compatibility. Modern nozzles should accommodate various fuel types. Some may support alternative fuels as well. This adaptability reflects the growing diversity in fuel usage. However, not all nozzles may meet your needs. Research is vital. An informed decision leads to a more satisfying experience. It’s essential to weigh these features carefully.

When analyzing leading fuel nozzle brands, several factors are critical. Efficiency and design are paramount. A well-designed nozzle reduces spillage and enhances fuel flow. Look for nozzles that offer adjustable flow rates. This feature can save fuel and reduce costs over time.

Tips: Always check compatibility with your fuel system. Different systems may require unique nozzles. Using an incompatible nozzle can lead to inefficiencies.

Durability is another key aspect. Nozzles should be made from robust materials that withstand harsh conditions. Corrosion resistance is vital. Poor-quality materials can lead to leaks and waste. Examine user reviews to gauge long-term performance. However, some reviews may be flawed or overly biased.

Tips: Regular maintenance is essential. Clean the nozzle frequently to prevent blockages. This simple practice can enhance its lifespan significantly.

When selecting a nozzle, consider price versus performance. High-priced options aren't always the best. Some budget-friendly nozzles perform just as well. Collect data and compare specifications before making a decision. Remember, what works for one may not work for all. Stay informed and make choices suited to your needs.

| Nozzle Type | Flow Rate (GPM) | Material | Compatibility | Price ($) |

|---|---|---|---|---|

| Standard Nozzle | 10 | Aluminum | Gasoline, Diesel | 40 |

| Automatic Shutoff | 9 | Plastic | Gasoline | 50 |

| High Flow Nozzle | 15 | Stainless Steel | Diesel | 65 |

| Safety Nozzle | 8 | Composite | Gasoline, Biodiesel | 45 |

| Nozzle with Swivel | 11 | Aluminum | Gasoline, Diesel | 55 |

When considering fuel nozzles, safety standards are paramount. Regulations vary by region, impacting design and functionality. Manufacturers must comply with specific guidelines. These rules ensure that fuel is delivered safely and minimizes spills. However, not all nozzles meet these standards. Checking compliance is crucial for safe operation.

Environmental regulations also play a significant role. Many countries push for tools that reduce emissions. Nozzles must limit vapor release during refueling. Despite advancements, some existing models still fall short of these requirements. This gap invites discussions on the need for upgrades. New technologies emerge constantly, aiming to bridge this disconnect.

In practice, it’s essential to consider the materials used in nozzle construction. Certain materials hold up better against corrosion and wear. Yet, some users still choose cheaper options that may not last. This choice raises questions about long-term safety and environmental impact. Fuel nozzles are a vital part of the fueling system. They must meet evolving standards while providing reliable service.

Fuel nozzles are critical for efficient fuel transfer. To ensure optimal performance, maintenance is essential. Regular inspection can help identify potential issues early. Look for cracks, leaks, or worn-out parts. These problems can lead to inefficiencies and increased costs.

Cleaning the nozzles is another vital step. Dirt and residues can affect fuel flow. Use appropriate cleaning solutions to ensure every component is free from blockages. Pay special attention to the filters; they often accumulate dirt quickly. Ignoring this can cause performance issues down the line.

Lastly, check the calibration of nozzles regularly. An improperly calibrated nozzle may dispense incorrect amounts of fuel. This can result in financial loss and operational headaches. Keeping a log of maintenance can help track changes and improve the overall performance of your fuel system. Small investments in maintenance can pay off significantly in the long run.