The coating powder machine industry has seen substantial growth in recent years. According to a report by Smith Manufacturing Insights, the market size is projected to increase by 8% annually through 2026. This growth highlights the rising demand for efficient coating solutions across various sectors.

Experts like Dr. Emily Chen emphasize the importance of choosing the right equipment. She states, "Selecting the perfect coating powder machine can drastically enhance productivity and product finish." Her insights underline the technical specifications crucial for optimal performance.

As businesses seek quality and efficiency, understanding the features of coating powder machines becomes essential. However, navigating the myriad options can be overwhelming. Not every machine meets the needs of every application. Careful assessment and expert guidance are vital.

Coating powder machines come in various types. They are essential in industries such as automotive, furniture, and electronics. These machines apply a dry powder coating to surfaces, creating a durable finish. Some machines use electrostatic processes. Others rely on fluidized beds. Each type suits different applications.

When choosing a machine, consider the coating material. Common options include polyester, epoxy, and hybrid powders. Each material has unique properties. For example, epoxy offers excellent adhesion, while polyester provides better UV resistance. Assess your specific needs carefully.

Tips: Always evaluate your workspace. Make sure you have enough ventilation. Poor airflow can ruin coatings. Test the machine's efficiency. Run samples before full production. This helps identify possible issues early. Maintenance is key. Regularly clean the equipment to ensure optimal performance. Neglecting this step can lead to complications.

Remember, the right machine can greatly improve your productivity. However, understanding your requirements is crucial. Don't rush into a purchase without thorough research. Take your time to find the best fit for your needs.

When selecting a coating powder machine, key features greatly influence performance and efficiency. One of the top considerations is the uniformity of the coating. Industry reports indicate that a machine with advanced electrostatic technology can achieve coat thickness variations as low as 5%. Such precision helps maintain high-quality standards in the final product.

Another essential feature is the machine’s operating temperature range. A broader range allows for versatility in material types. Data shows that machines reaching temperatures up to 200°C can effectively handle various coatings. However, this flexibility comes with a trade-off; higher temperatures may increase operational costs and energy consumption.

Additionally, the ease of maintenance cannot be overlooked. Machines requiring frequent repairs may disrupt production. Some reports suggest that about 25% of downtime in coating operations is linked to maintenance issues. Thus, seeking a machine with a user-friendly design can reduce these challenges. Adaptability to different powder types is another factor impacting long-term usability. Many users may initially overlook this, but it directly affects overall efficiency and output quality.

| Model | Type | Max Coating Thickness (mm) | Voltage (V) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| APM-2000 | Electrostatic | 200 | 220 | 150 | 1500 |

| CPC-150 | Fluidized Bed | 150 | 220 | 120 | 1200 |

| FPM-600 | Manual | 180 | 110 | 200 | 800 |

| EPM-400X | Automatic | 220 | 380 | 250 | 2500 |

| SPM-100 | Electrostatic | 100 | 120 | 75 | 700 |

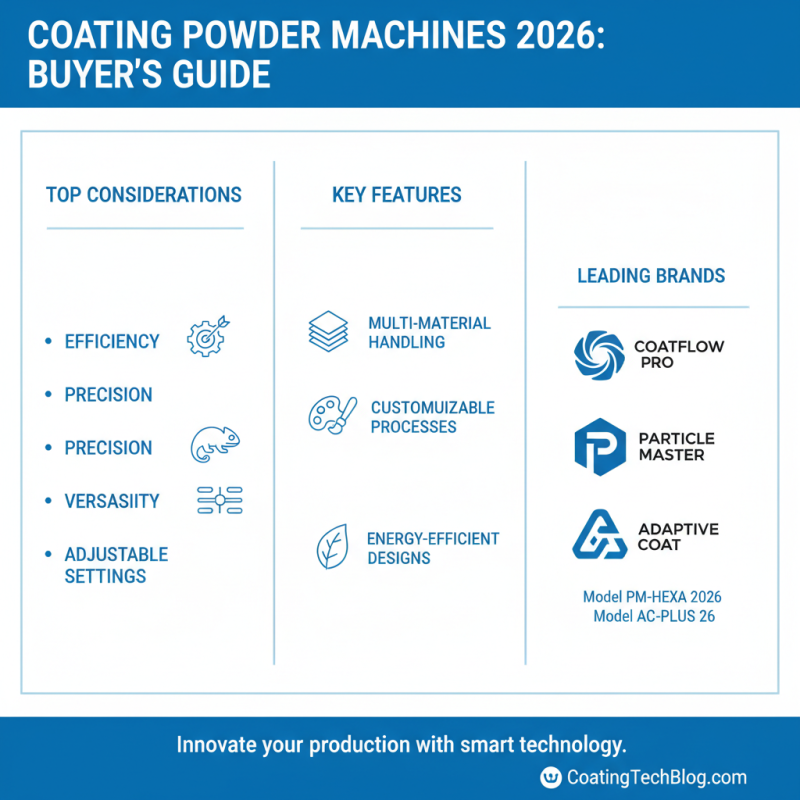

When looking for coating powder machines in 2026, knowing the top brands and models is essential. Many machines now focus on efficiency and precision. They are designed to handle a variety of materials, making them versatile. Look for machines that offer adjustable settings. This feature allows for better customization of the coating process.

**Tips:** Always check user reviews. They can reveal common issues and the real performance of the machines. Pay attention to the warranty period. A solid warranty provides peace of mind.

Some brands innovate with technology, yet others stick to traditional methods. This can be frustrating when trying to decide which machine suits your needs best. Ensure you consider your production scale. A machine suitable for small businesses might not meet the demands of larger operations.

**Tips:** Always assess the maintenance requirements. Machines that are harder to maintain can lead to increased downtime. Look for user-friendly interfaces to ease operation.

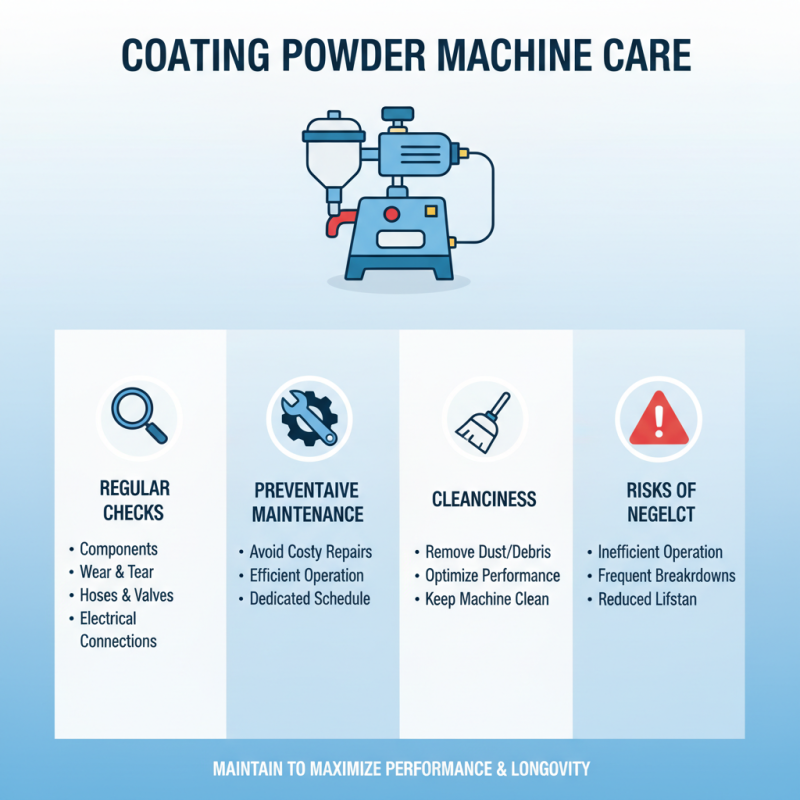

Proper maintenance and care are crucial for any coating powder machine. Regularly checking the machine's components can prevent costly repairs. Look for any signs of wear. Pay attention to hoses, valves, and electrical connections. Inadequate care can lead to inefficient operation. Dust and debris build-up can affect performance. Keep the machine clean. A dedicated maintenance schedule can help.

Lubrication is another key area. Check moving parts for smooth operation. Apply lubricant as needed, but avoid overdoing it. Too much can attract dirt, leading to damage. Always refer to your machine’s manual for specific guidelines. Remember, neglecting small issues can lead to bigger problems down the line.

Training staff on proper use is also important. Ensure everyone understands the machine’s functionalities. A lack of knowledge can result in improper handling. Mistakes can shorten the machine's lifespan. Encourage regular feedback from operators. Address any concerns promptly. This fosters a culture of care and responsibility towards the equipment.

When choosing a coating powder machine, budget is crucial. Understanding your financial limitations helps narrow your options. Some machines are affordable but lack advanced features. Others are high-priced yet offer exceptional performance.

Consider your production needs. Will you run small batches, or do you need to scale up? Low-end models may suffice for small projects. However, larger operations may require more robust machines. Each type has its pros and cons. Sometimes, spending more can lead to better quality and durability.

Tips: Always include maintenance costs in your budget. Cheap machines can lead to high repair bills. Ask for warranties, even if they increase the price. Evaluate the machine’s energy consumption. Higher efficiency can save money long-term. Be mindful of your choices. Balancing quality and cost is not always easy.