The demand for efficient and high-quality finishing solutions in various industries has led to a significant rise in the adoption of Automatic Spray Coating Machines. According to a recent market analysis by Grand View Research, the global market for spray coating is projected to reach $22.7 billion by 2025, highlighting the critical role that these machines play in enhancing production capabilities. As industries increasingly seek to optimize their operations while reducing labor costs and material waste, investing in an Automatic Spray Coating Machine has become a strategic priority.

Industry expert Dr. John Smith, a leading figure in industrial automation, emphasizes the importance of selecting the right equipment: "The effectiveness of an Automatic Spray Coating Machine not only influences the quality of the final product but also impacts the overall efficiency of the manufacturing process." With such high stakes, it is crucial for manufacturers to be well-informed when choosing the best machine tailored to their specific needs. This article provides the top 10 tips to guide you through the selection process, ensuring that you invest wisely in technology that drives innovation and future growth in your production line.

When selecting an automatic spray coating machine, there are several key factors to consider that can significantly impact the efficiency and quality of your coating process. One of the most crucial aspects is the machine's compatibility with the type of materials you intend to use. Make sure the sprayer can handle various coatings, such as paints, varnishes, or specialized coatings, without compromising performance.

Another important factor is the machine's precision and control features. Machines that offer adjustable pressure settings and spray widths can help achieve a more uniform coating and reduce waste. For instance, consider investing in a model that allows for fine-tuning of spray parameters, which can enhance the quality of the finish on your projects.

Additionally, maintenance and support should be prioritized. A reliable machine should come with easy access to parts and a solid warranty to mitigate downtime in your production line. Look for machines that provide comprehensive customer support and user-friendly maintenance guides, making it easier for your team to perform routine checks and repairs. By considering these factors, you can ensure that you choose the best automatic spray coating machine for your needs.

When selecting the best automatic spray coating machine, it’s essential to understand the various spray coating technologies available, each with unique advantages and applications. For example, new innovations in coating technologies, such as high-velocity oxy-fuel (HVOF) techniques, offer superior chemical and wear resistance, making them ideal for demanding environments. According to industry reports, the corrosion under insulation and spray-on insulation coatings market is projected to grow from USD 2,039.7 million in 2024 to USD 3,071.1 million by 2032, reflecting the increasing demand for reliable protective coatings across industries.

Additionally, advancements in graphene coatings have enabled functional applications ranging from high-performance adhesives to innovative anti-corrosive solutions based on modified epoxy coatings. These coatings often incorporate active species that enhance protection and durability, an essential consideration for anyone looking to invest in an automatic spray coating machine.

When choosing your machine, consider the spray technology suited for your projects. Ensure it can accommodate diverse coating materials, including those used in microarray patches and next-gen fusion reactors. Focus on machines that offer versatility, efficiency, and adaptability, as these features are vital for staying competitive in a rapidly evolving market.

| Tip | Description | Technology Type | Suitable Applications | Efficiency |

|---|---|---|---|---|

| 1. Know Your Needs | Assess your production needs before selecting a machine. | Airless | Heavy-duty coatings | High |

| 2. Consider Automation Level | Decide how automated you need the process to be. | Fully Automated | Mass production | Very High |

| 3. Check Finish Quality | Ensure the machine can achieve the desired finish quality. | Electrostatic | Fine finishes | High |

| 4. Review Maintenance Needs | Consider the upkeep and servicing required for the machine. | Conventional | General applications | Moderate |

| 5. Evaluate Cost Efficiency | Analyze the cost against the efficiency of the machine. | Robotic | Complex shapes | High |

| 6. Investigate Material Compatibility | Ensure the machine works with the materials you plan to use. | HVLP | Light coatings | Efficient |

| 7. Assess Speed and Output | Determine the speed and number of units produced per hour. | Cross-flow | Batch processing | Moderate |

| 8. Look for Environmental Features | Machines with lower emissions and waste are preferable. | Eco-Friendly | General use | High |

| 9. Research User Reviews | Check feedback from other users to gauge performance. | Various | Diverse applications | Variable |

| 10. Consult with Experts | Seek advice from professionals before making a decision. | Industry Benchmark | Specialized coatings | High |

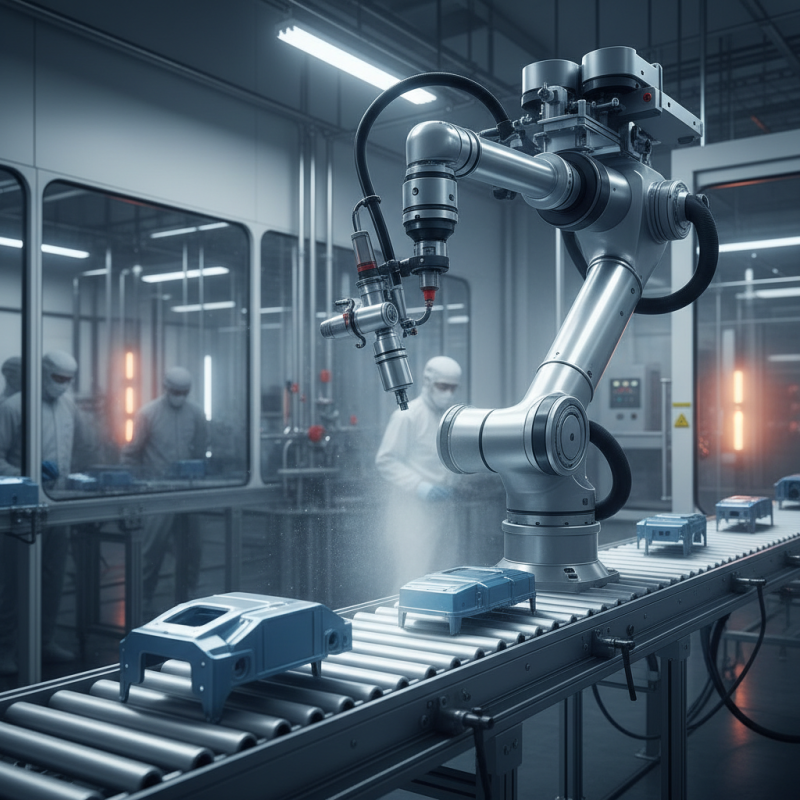

When selecting an automatic spray coating machine, understanding its capacity and efficiency is crucial. Capacity typically refers to the volume of material the machine can process in a given time frame. According to a report by MarketsandMarkets, the global market for spray coating systems is expected to reach $5.6 billion by 2026, highlighting the growing demand for efficient machinery that can handle large-scale operations. A machine with adequate capacity not only enhances productivity but also minimizes downtime, making it an essential factor in your purchasing decision.

Efficiency is equally important, as it directly impacts operational costs and quality of output. An efficient spray coating machine should have a high transfer efficiency rate, ideally over 80%, which means that a significant percentage of the coating material is actually deposited on the target surface. Additionally, consider the machine's ease of maintenance and setup time, as these factors further influence overall efficiency.

When choosing a machine, it’s beneficial to look for those with modular designs, allowing for easy upgrades and scalability. Also, ensure the machine can handle various coatings without requiring extensive adjustments—this flexibility can substantially improve workflow. Prioritizing these elements will lead to a more informed decision that aligns with your production needs.

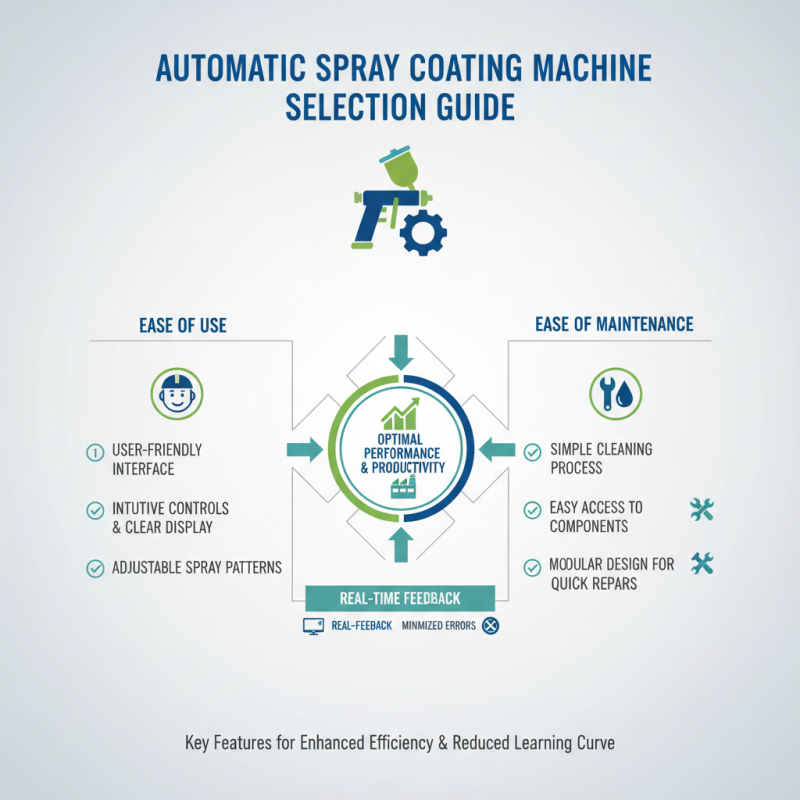

When selecting an automatic spray coating machine, assessing its ease of use and maintenance for operators is crucial. A user-friendly interface can significantly enhance productivity and reduce the learning curve for new employees. Machines equipped with intuitive controls and clear display panels allow operators to manage settings effortlessly, ensuring consistent application and minimizing errors. Features such as adjustable spray patterns and real-time feedback further contribute to an efficient operation, making it essential to prioritize these capabilities during the selection process.

Additionally, maintenance is a key factor that directly impacts the longevity and performance of the equipment. Machines that allow for easy access to critical components facilitate routine cleaning and servicing, thus reducing downtime. Look for features like quick-release covers, self-cleaning mechanisms, and easily replaceable parts to streamline upkeep. Investing in a machine with straightforward maintenance requirements not only saves time and costs but also empowers operators to keep the equipment running smoothly, ensuring that production schedules remain on track.

When considering an automatic spray coating machine, it is essential to compare the costs and features of different models to find the best fit for your needs. The Cold Spray Coatings Market, for instance, is projected to grow significantly, reaching $2.0 billion by 2034, highlighting the increasing demand for advanced coating technologies. With a dominant market share of 38.5% in nickel materials, it's clear that material selection plays a crucial role in performance and application flexibility.

Moreover, innovations in robotic spray painting are enhancing surface quality through optimization techniques powered by machine learning. This technological advancement not only improves the accuracy of coating processes, especially vital in industries like automobile manufacturing, but also ensures that products meet high standards consistently. When selecting a machine, evaluating these features against cost can lead to better investment decisions and operational efficiencies.