In the quest for efficient cooling solutions, Atomizing Misting Nozzles have emerged as a pivotal technology. According to a recent market analysis by Global Industry Analysts, the global misting system market is projected to exceed $3 billion by 2027, spurred by increased applications in outdoor spaces and industrial environments. These systems are essential for controlling temperatures and enhancing comfort, especially in regions with extreme heat.

Dr. Emily Carter, an expert in fluid dynamics, emphasizes, "Atomizing Misting Nozzles can significantly improve cooling efficiency while reducing water usage." This underscores the innovative design of these nozzles, which atomize water into fine droplets. However, it is important to recognize that not all systems perform equally. Proper installation and maintenance are crucial for maximizing their effectiveness.

While Atomizing Misting Nozzles offer substantial benefits, challenges remain. Many users overlook the impact of nozzle placement and water quality on performance. Understanding these dynamics can be the difference between mediocre results and exceptional cooling solutions. As the industry grows, a reevaluation of existing practices becomes necessary to ensure optimal use of Atomizing Misting Nozzles.

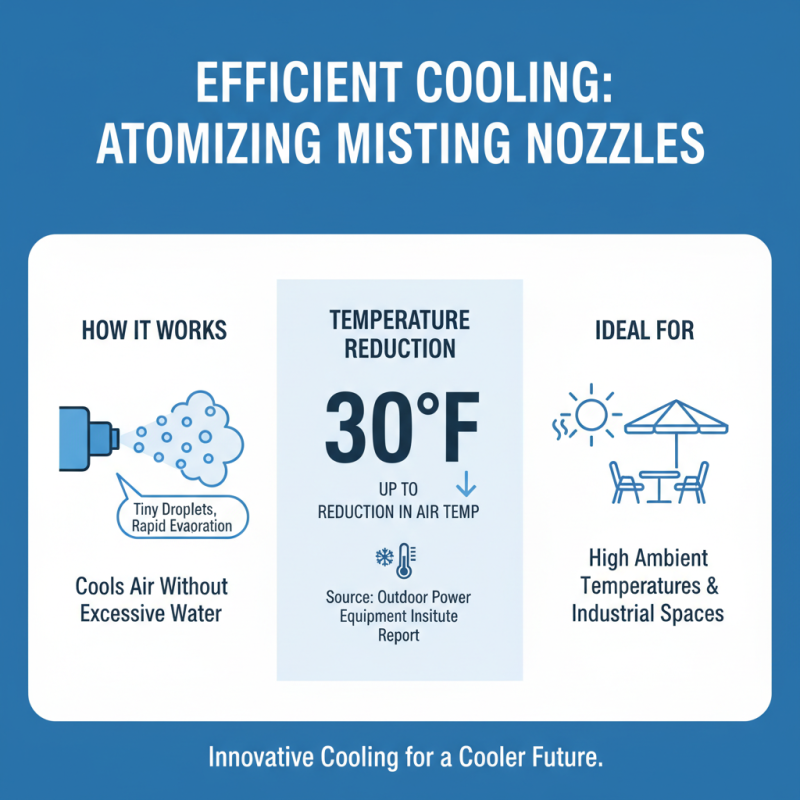

Atomizing misting nozzles offer an innovative solution for cooling spaces efficiently. These nozzles create tiny water droplets that rapidly evaporate, providing effective cooling without excessive water usage. In fact, according to a report from the Outdoor Power Equipment Institute, systems using atomizing misting can reduce air temperature by up to 30°F. This efficiency plays a crucial role in areas with high ambient temperatures.

Understanding their functionality is essential. Atomizing nozzles operate at high pressure, forcing water through small orifices. This process generates fine mist, ideal for evaporative cooling. Industry research indicates that the right nozzle design can enhance misting performance. However, users must consider factors like water quality and system maintenance. Poor water quality can lead to mineral buildup, affecting nozzle performance. Regular cleaning is necessary but often overlooked.

Moreover, environmental conditions impact misting efficiency. High humidity can decrease evaporation rates, limiting cooling effectiveness. In some cases, users report inconsistent results due to variations in weather. Monitoring these factors is vital for optimal system performance. Engaging in routine assessments can help users avoid potential pitfalls and enhance overall cooling strategies.

Atomizing misting nozzles play a crucial role in creating effective cooling solutions. These devices use high pressure to disperse water into fine droplets. This technology significantly enhances evaporative cooling. According to industry research, proper nozzle selection can improve cooling efficiency by up to 30%.

There are several types of atomizing misting nozzles available. High-pressure nozzles work well for outdoor spaces, providing a cool surround. Low-pressure nozzles are ideal for more confined areas. Each type offers unique advantages. Adjusting nozzle spacing can also affect cooling performance. Keeping nozzles clean ensures optimal function and longevity.

Tips for choose nozzles wisely: always consider the environment. What works in one area may not work in another. Testing different patterns enables better results. Regular maintenance is key. Dirty nozzles can lead to inconsistent misting and reduced cooling.

| Nozzle Type | Drop Size (microns) | Application Area (sq ft) | Water Flow Rate (GPH) | Ideal Use |

|---|---|---|---|---|

| High Pressure Misting Nozzle | 5-10 | 100-200 | 1-2 | Outdoor patios |

| Low Pressure Misting Nozzle | 30-50 | 200-400 | 2-5 | Agricultural cooling |

| Fan-Integrated Misting Nozzle | 10-20 | 150-300 | 1-3 | Indoor cooling |

| Ultrasonic Misting Nozzle | 1-5 | 50-100 | 0.5-1 | Hydroponics |

| Portable Misting Nozzle | 15-25 | 100-150 | 0.5-1.5 | Event cooling |

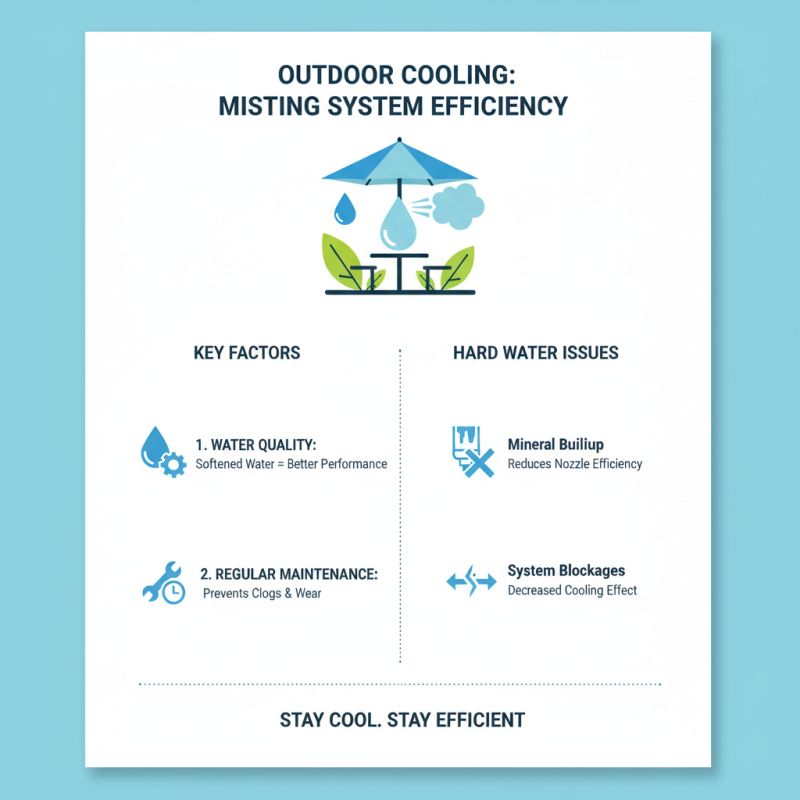

Misting systems can provide exceptional cooling in outdoor spaces. However, their efficiency hinges on various key factors. One major factor is the water quality used in the system. Hard water can lead to mineral buildup, affecting nozzle performance. Regular maintenance checks are necessary to avoid this issue.

Another critical consideration is the nozzle type. Different nozzles create various droplet sizes, impacting how effectively the mist cools the air. Fine droplets evaporate quickly and cool better, while larger droplets may fall before evaporating.

Tips for optimizing cooling solutions include ensuring even spacing between nozzles. This arrangement helps distribute the mist uniformly. Monitor climate conditions regularly too. High humidity can reduce evaporation rates, diminishing the cooling effect. Adjusting water pressure can also enhance misting performance, creating an effective balance for optimal cooling.

When it comes to installing misting nozzles, proper placement is key. Nozzle positioning directly impacts cooling efficiency. Reports indicate that optimal placement can reduce ambient temperatures by up to 30%. Ideal locations include patios, outdoor seating areas, and even industrial zones where heat buildup is common. Each nozzle should be spaced according to its spray pattern. This can ensure even coverage and avoid dry spots.

Water quality is another essential factor. Hard water can clog nozzles and reduce effectiveness. Regular maintenance is crucial. Cleaning the nozzles every few weeks can help maintain their performance. Additionally, using filters can prevent mineral buildup. Ignoring these details can lead to a decrease in cooling efficiency.

It’s important to consider the timing of operation as well. Using misting systems during peak heat hours maximizes their benefits. However, running them too long might lead to wastage. Understanding local humidity levels is crucial. High humidity can make mist less effective. Experimentation may be needed to find the best settings for different conditions. This aspect often requires ongoing adjustments and monitoring.

Misting systems are popular for their effective cooling capabilities. However, regular maintenance is crucial for longevity. A 2022 report indicates that 70% of misting failures result from poor upkeep. This statistic emphasizes the need for regular inspections and cleaning routines.

One effective tip is to check nozzles for blockages. Dirt and minerals can accumulate, leading to reduced mist output. Clean the nozzles every few weeks. Even a small blockage can affect performance. Another helpful practice is to inspect hoses and connections regularly. Leaks can waste water and reduce system efficiency.

Remember, not all components are built to last. Corrosion or wear can affect spray patterns. Replace worn-out parts promptly to maintain efficiency. Keeping records of inspections can also help track system health. Focus on preventive actions to ensure reliable cooling year-round. A proactive approach enhances your system's performance significantly.