In the world of industrial painting, choosing the right equipment can significantly impact efficiency and quality. The wide range of Industrial Painting Equipment available today caters to various professional needs. From sprayers to protective gear, each tool can make a difference.

Not all equipment is created equal. Some may lack durability. Others might not provide the coverage needed for large surfaces. Professionals often face challenges finding the perfect fit for their projects. Understanding these nuances can lead to better decisions and improved results.

As we approach 2026, exploring the best tools and innovations is critical. Each piece of equipment can enhance productivity, but it requires careful selection. Professionals must reflect on their unique requirements and the specific demands of their job. This landscape of Industrial Painting Equipment offers up both opportunities and pitfalls to navigate.

When choosing industrial painting equipment, several key considerations can significantly impact your decision. First, think about the specific tasks you will perform. Will you be painting large surfaces or intricate designs? The type of job influences the tools you'll need. For instance, spray guns work well for large areas, while brushes are better for detail work.

Another factor to consider is the material you’ll be using. Water-based paints often require different tools compared to solvent-based options. Not all equipment handles all materials effectively. Pay attention to compatibility to ensure a smooth application.

Budget plays a crucial role too. High-quality equipment can be costly, but investing wisely can improve efficiency. Some tools may wear out quickly, leading to additional costs. Be cautious and reflect on your long-term needs versus immediate wants. Ultimately, the right balance can elevate your painting projects, but it’s easy to overlook these aspects amid the excitement of purchasing new gear.

Industrial painting tools come in various types, each designed for specific applications. One essential tool is the spray gun. It provides a fine mist of paint, allowing for an even coat on large surfaces. However, achieving the perfect spray can be tricky. Users often struggle with adjusting the nozzle settings, leading to overspray or uneven texture.

Brushes are another cornerstone in industrial painting. While they are crucial for detail work, they also require skill. A poor brush choice can leave streaks and imperfections. Many painters face challenges when blending colors, which can ruin the final appearance. Fine-tipped brushes help, but they demand patience.

Rollers are often favored for larger areas. They cover spaces quickly, but may miss tight corners. Painters frequently find themselves needing touch-ups after using rollers. This can be frustrating, especially when time is limited. Selecting the right nap length is key, yet many overlook it, resulting in uneven application. Each tool has its place and purpose, but mastery comes from experience and thoughtful practice.

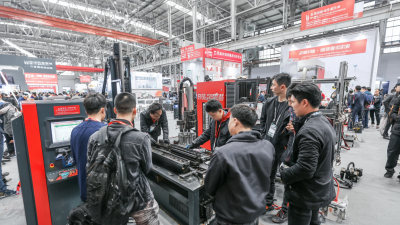

Choosing the right industrial painting equipment can be daunting. The industry is flooded with options. Reports indicate that 65% of professionals struggle to find the right tools for specific jobs. This highlights the importance of quality and reliability in equipment choices.

Among the top brands in industrial painting, performance is key. Statistics show that equipment durability can affect project timelines. For example, tools that fail under pressure can lead to costly downtime. An analysis from a recent market survey reveals that 30% of professionals experience delayed projects due to equipment failures. Recognizing these challenges can guide purchases toward more dependable options.

Looking at the available choices, many products provide versatility. However, not all tools can handle varied environments. Inconsistent quality can result in subpar finishes. Nearly 15% of workers admitted they often resort to repairs due to poor initial results. This reflects the need for thorough research and acknowledgement of limitations among various brands and tools. All these factors deeply affect workflow and productivity.

To maintain painting equipment effectively, regular care is essential. Clean your brushes and rollers after each use. Leftover paint can harden and ruin them. Rinse them thoroughly and reshape the bristles. This simple step extends their lifespan significantly.

Proper storage matters too. Keep your tools in a dry, cool place. Humidity can cause rust or mildew. Invest in tool organizers to avoid unnecessary damage from clutter. Also, check for wear and tear regularly. Replace worn-out components to ensure optimal performance.

Inspecting your spray guns is crucial. Clean the nozzles carefully to prevent clogging. A little attention can save you from costly repairs. Remember, taking small steps now can make a huge difference later on. Prioritizing maintenance lets you achieve better results on the job.

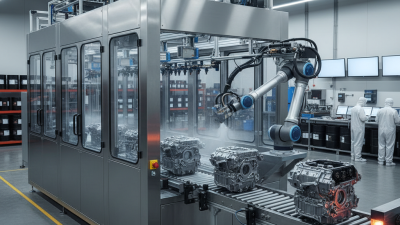

Innovations in industrial painting technology are crucial for 2026. The industry is seeing significant changes with advanced methods and tools. New spray systems promise better coverage and reduced waste. These innovations can help save both time and resources. Autonomous robots for painting tasks are also emerging. They can navigate complex surfaces and deliver consistent results. Yet, they are not flawless and do require skilled operators.

While these advancements are exciting, challenges remain. Training workers to effectively use new technologies is essential. Some operators may resist these changes. There can be a learning curve, and mistakes may occur. It is vital to assess the effectiveness of new tools regularly. Continual feedback loops are necessary for improvement.

Safety features are becoming more sophisticated. Enhanced personal protective equipment (PPE) is being developed. However, workers still face risks. Ensuring that everyone understands these risks is important. Addressing concerns can promote a safer working environment. Therefore, the integration of new technology should involve all stakeholders, fostering communication and collaboration.

| Equipment Type | Key Features | Application Areas | Estimated Price ($) | User Rating |

|---|---|---|---|---|

| Airless Paint Sprayer | High pressure, fast coverage | Industrial machinery, large equipment | 800 - 1200 | 4.5/5 |

| Electrostatic Sprayer | Minimal overspray, uniform coating | Automotive, manufacturing | 1500 - 2500 | 4.7/5 |

| Automated Painting Robot | Precision, high speed, programmable | Large-scale production, precision components | 50000 - 100000 | 4.9/5 |

| HVLP Spray Gun | Low overspray, fine finish | Furniture, automotive refinishing | 200 - 500 | 4.3/5 |

| Pressure Washer | High pressure, versatile cleaning | Surface preparation, cleaning | 300 - 800 | 4.6/5 |