In the quest for efficient performance, choosing the right Cutting Machine Battery is crucial. A reliable battery can make a significant difference in productivity and overall results. The 2026 options available prioritize efficiency, durability, and fast charging capabilities.

Batteries come in various types, each presenting unique advantages and downsides. For instance, lithium-ion batteries are popular for their longevity. However, they can be expensive, and not all brands offer guaranteed quality. Understanding the differences can help in making an informed decision.

Additionally, considering compatibility with different cutting machines is essential. Not every battery fits every model. Ensuring the right pairing can prevent waste and enhance performance. Researching and reflecting on what works best for your needs can lead to better outcomes. The right Cutting Machine Battery can ultimately transform the way you work, making it an important investment.

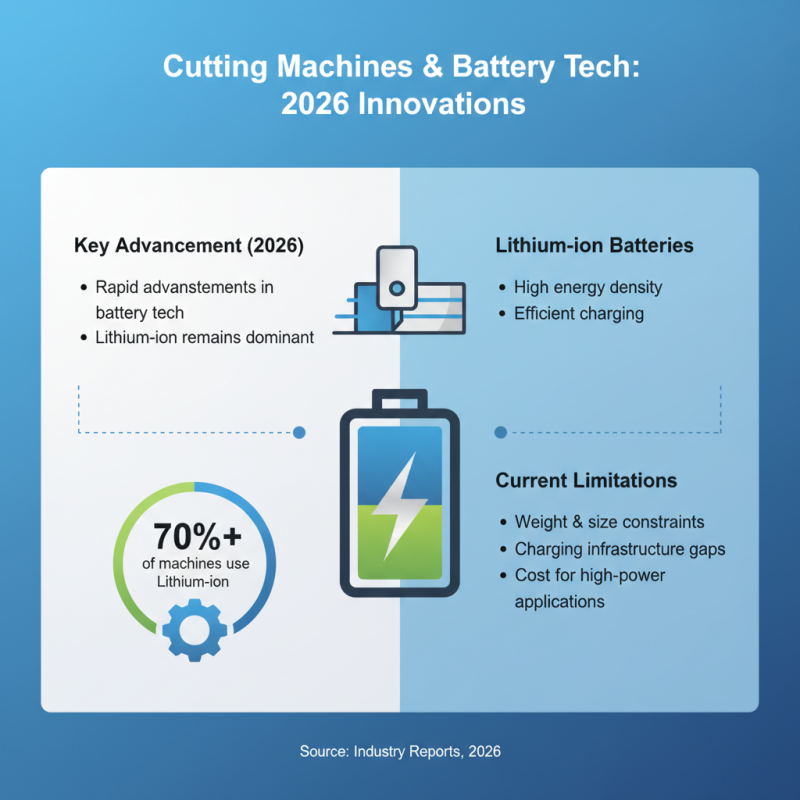

Cutting machines are vital in various industries, including textiles, metal fabrication, and woodworking. In 2026, battery technology for these machines reflects rapid advancements. Lithium-ion batteries remain predominant. They offer high energy density and efficient charging. According to industry reports, over 70% of cutting machines are now equipped with this technology. However, limitations exist.

Battery lifespan is a constant concern. On average, lithium-ion batteries last only 2-3 years, depending on usage intensity. Additionally, extreme temperatures can affect performance. Newer technologies like solid-state batteries show promise. They offer longer lifespans and enhanced safety. Despite this, solid-state solutions are still costly. Only about 12% of manufacturers are considering them for their cutting machines.

Moreover, researchers are exploring alternatives like lithium iron phosphate (LFP) batteries. LFP batteries provide better thermal stability. Their life cycle is longer than that of traditional lithium-ion batteries. Despite their benefits, the energy density can be lower. As a result, they may not be suitable for all cutting applications. Balancing cost, efficiency, and longevity remains a challenge in the industry.

When selecting a battery for your cutting machine, several key factors come into play. The battery type impacts the overall efficiency. Lithium-ion batteries offer longer life and faster charging. However, lead-acid batteries might suit other needs better due to cost considerations. It's essential to weigh the pros and cons of each type carefully.

Capacity is another critical factor. A high-capacity battery can power your machine for extended periods. Look for batteries that provide a reliable runtime for your specific tasks. Short runtimes can disrupt your workflow and lead to frustration.

Tip: Always check the voltage requirements of your cutting machine before purchasing a battery. Compatibility is crucial.

Weight and portability matter as well. A lightweight battery will not hinder the maneuverability of your machine. Conversely, heavier batteries might cause fatigue during prolonged use.

Tip: Consider the environment where you'll use the cutting machine. Extreme temperatures can affect battery performance. Take extra precautions if you frequently work in harsh conditions. Reflect on these choices to enhance your cutting experience.

In 2026, cutting machines are becoming essential across various industries. The efficiency of these machines greatly depends on their batteries. Several top battery brands emerge as leaders in performance and reliability. Researchers point out that lithium-ion batteries remain the preferred choice due to their energy density and lifespan. In fact, reports indicate that over 75% of cutting machine users favor lithium-ion technology for its efficiency.

When selecting batteries, features like charge time and cycle durability are crucial. Data shows that high-quality batteries can endure up to 2,000 charge cycles. This longevity directly translates to cost savings over time. Still, some users find it challenging to switch to newer technologies. They often hesitate due to initial costs. However, the long-term benefits often outweigh the upfront investment.

Battery weight is another critical factor. Lighter batteries enhance mobility. Connectivity options are also improving. Some brands are now including smart technology to monitor battery performance. This offers users real-time data on usage patterns. Yet, not every brand provides the same level of technology integration. Users must be aware of these variances. It becomes vital to make informed choices based on specific needs and industry demands.

This chart presents an overview of various battery options for cutting machines in 2026, rated on a scale from 1 to 10 based on their performance efficiency. Lithium-Ion batteries rank the highest, indicating their superiority in performance.

When selecting a cutting machine, battery performance and lifespan are crucial factors. Different battery types provide varying levels of efficiency. Lithium-ion batteries are commonly favored for their longer life cycle. They can last for several years with proper care. However, they come at a higher upfront cost.

Lead-acid batteries, on the other hand, are cheaper but have a shorter lifespan. They may not hold a charge as well over time. This could lead to inconsistent performance during tasks. Users often overlook the importance of regular maintenance, which can extend battery life significantly. Ignoring these practices might result in frequent replacements.

Evaluating actual usage scenarios is essential. Some may prefer lightweight options for portability, while others might prioritize long duration over weight. It's a balancing act that requires careful thought. Ultimately, understanding the specific needs and environments where the cutting machine will be used can guide users toward the best battery choice for their situation.

In recent years, the demand for

cutting machines has surged, especially in industries like

construction and

manufacturing. As these machines evolve, so do their power sources.

Innovative battery technologies are at the forefront of this transformation.

Reports indicate that the global market for cutting machine batteries is expected to grow at a

CAGR of 8% through 2026. This growth is driven by a push for more

efficient and sustainable energy solutions.

One exciting area is the development of

lithium-sulfur batteries. These batteries promise higher energy densities

compared to traditional lithium-ion variants. Early studies suggest that lithium-sulfur systems can achieve

up to 500 Wh/kg. Despite these advancements, challenges remain.

Durability and cycle life

still need significant improvement. Many existing batteries degrade quicker than desired, impacting overall

machine performance.

Another intriguing innovation is the incorporation of

solid-state technology. Solid-state batteries can offer inherent safety and

efficiency advantages. They utilize solid electrolytes instead of liquids, which can mitigate risks of leakage.

Research estimates a potential 50% increase in energy density with this technology.

However, the high manufacturing costs could pose a barrier to widespread adoption. Balancing efficiency, safety,

and cost will be crucial as the industry looks ahead.