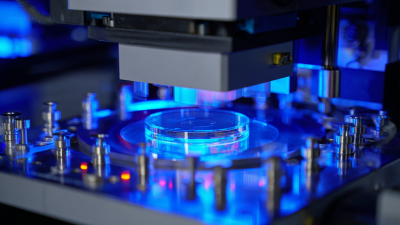

In the rapidly evolving landscape of advanced manufacturing, efficiency and precision have become paramount. One of the cutting-edge technologies driving these crucial elements is the Ultrasonic PP Welding Machine. Renowned for its ability to provide strong, reliable welds without the need for additional adhesives or mechanical fasteners, this innovative machinery stands out as a game changer in various industrial applications. As industries continue to seek ways to enhance production quality while minimizing waste, the Ultrasonic PP Welding Machine has emerged as an essential tool, catering to diverse manufacturing needs.

This article delves into the top 10 Ultrasonic PP Welding Machines expected to dominate the market by 2025. We will explore their unique features, technological advancements, and the potential they hold for transforming manufacturing processes. With a focus on how these machines can optimize operations, improve product durability, and reduce costs, manufacturers will find valuable insights to make informed decisions. By understanding the benefits and capabilities of these ultrasonic welding machines, companies can stay ahead in the competitive world of advanced manufacturing.

The ultrasonic PP welding technology is rapidly evolving, significantly impacting advanced manufacturing in 2025. As the demand for precision and quality in manufacturing processes increases, ultrasonic welding is becoming a preferred choice due to its ability to produce strong, consistent joins without the need for additional adhesives or fasteners. Recent market analysis indicates a steady growth trajectory for the ultrasonic welding industry, with expectations to reach USD 1,156 million by 2034 at a CAGR of 5.1%. This trend underscores the importance of adopting advanced welding technologies to stay competitive.

Tips for manufacturers considering ultrasonic PP welding include investing in training for personnel to ensure they are proficient with the latest technology. Additionally, evaluating and selecting the right ultrasonic equipment tailored to specific applications can significantly enhance productivity and quality. Partners in ultrasonic welding should also stay updated on innovations and emerging trends to capitalize on potential opportunities in the market. Embracing these strategies will ultimately lead to improved efficiency and product performance in the evolving landscape of manufacturing.

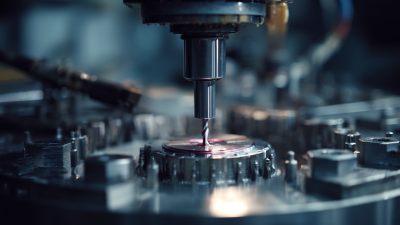

In the ever-evolving landscape of advanced manufacturing, ultrasonic PP welding machines are at the forefront, offering a multitude of features that enhance productivity and precision. The leading ultrasonic welding machines boast attributes such as rapid welding speeds, energy efficiency, and the capability to join intricate plastic components with minimal material deformation. Their ability to create strong, consistent welds makes them essential for manufacturers looking to streamline their operations and maintain high-quality standards in production.

When selecting an ultrasonic welding machine, consider the following tips: First, assess the specific requirements of your manufacturing process, such as the types of materials being welded and the desired production volume. This will help determine if an automatic, semi-automatic, or manual machine is most suitable. Additionally, examine the machine's integration capabilities with existing production systems to ensure a seamless workflow. Always prioritize models that offer robust technical support and service agreements to minimize downtime and maintain optimal performance.

As the ultrasonic welding machine market continues to grow, projected to reach over $1.14 billion by 2034, investing in state-of-the-art technology is crucial for staying competitive. Cutting-edge features like real-time monitoring systems and advanced control interfaces are becoming increasingly vital, enabling manufacturers to achieve higher consistency and efficiency in their welding operations.

The ultrasonic welding machines market is experiencing substantial growth, projected to reach a market size of USD 1,156 million by 2034, with a compound annual growth rate (CAGR) of 5.1%. This growth is primarily driven by the increasing demand for efficient and cost-effective manufacturing solutions across various industries. The recent comparative analysis of ultrasonic welding solutions highlights significant advancements in machine efficiency, which is crucial for manufacturers seeking to optimize their production processes.

The surge in the adoption of ultrasonic welding technology can be attributed to its ability to provide strong, durable joints with minimal thermal impact on the materials. As companies strive to enhance their production capabilities, a focus on the cost-effectiveness of these machines becomes paramount. Research indicates that investments in high-efficiency ultrasonic welding systems not only reduce operational costs but also improve overall product quality, further solidifying their role in advanced manufacturing settings. Industry leaders are now emphasizing the importance of selecting the right equipment to balance upfront costs with long-term benefits, as indicated in detailed market reports analyzing trends and growth determinants.

As we look towards 2025, the landscape of ultrasonic welding technology is set to evolve dramatically, driven by innovations that promise to reshape manufacturing dynamics. According to a report by ResearchAndMarkets, the ultrasonic welding market is projected to reach USD 1.75 billion by 2025, growing at a CAGR of 6.7% from 2020. This growth can be attributed to the increasing demand for lightweight and durable materials in various sectors, including automotive and consumer electronics, where ultrasonic welding excels in joining polypropylene (PP) components with precision and speed.

Future innovations are anticipated to enhance the efficiency and scalability of ultrasonic welding machines. Enhanced automation features, coupled with advanced frequency and power control systems, will not only optimize energy consumption but also improve weld quality. The integration of Industry 4.0 principles, such as IoT connectivity and machine learning algorithms, will enable real-time monitoring and predictive maintenance, thereby minimizing downtime and increasing productivity. According to a study by Mordor Intelligence, the adoption of smart manufacturing technologies like ultrasonic welding could improve process efficiency by up to 30%, underscoring the transformative potential of these advancements in modern manufacturing.

The environmental impact of Ultrasonic PP welding machines plays a crucial role in sustainable manufacturing practices. These machines utilize high-frequency ultrasonic vibrations to create strong bonds between polypropylene materials, resulting in minimal waste generation. Unlike traditional welding methods, which often require adhesives or additional substances, ultrasonic welding is a clean process that reduces harmful emissions and enhances energy efficiency. This contributes to a lower carbon footprint, making it an ideal choice for industries striving to adopt greener production methods.

Moreover, the longevity and durability of products manufactured using ultrasonic welding enhance their sustainability. By creating strong, reliable seams, these machines help in reducing the need for repairs or replacements, thereby extending the lifecycle of products. In addition, the recyclable nature of polypropylene ensures that end-of-life materials can be repurposed, further minimizing environmental impact. As manufacturers increasingly focus on sustainable practices, ultrasonic PP welding technology stands out as a viable solution that aligns profitability with ecological responsibility.