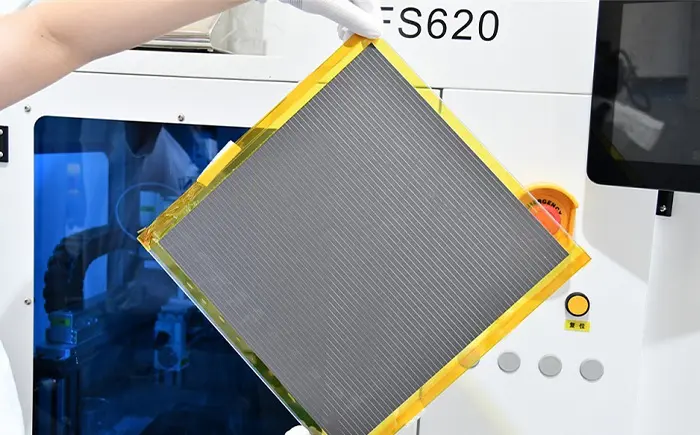

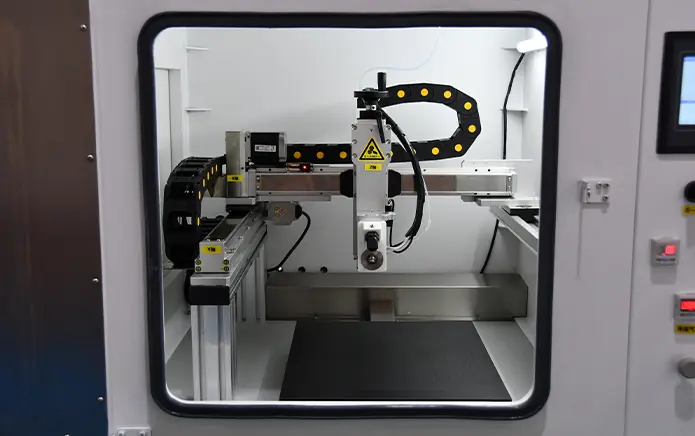

Benchtop Ultrasonic Vacuum Coating System FS620M

Advantage

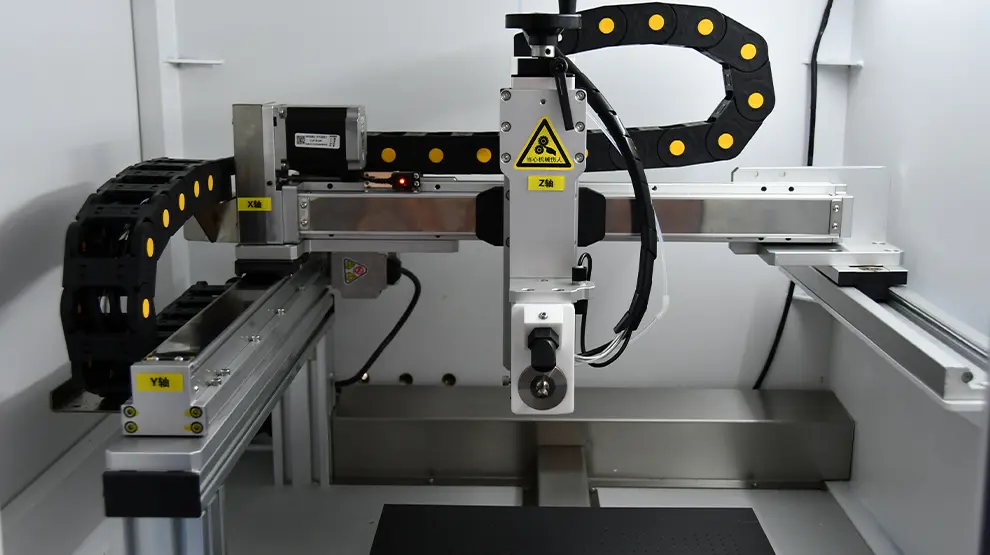

Product Configuration

-

Conventional Arrangement

1. Viscosity and solid content: Typically, viscosity is ≤ 30cps, and the suspension requires a solid content of no more than 20-30%

2. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1uL/min

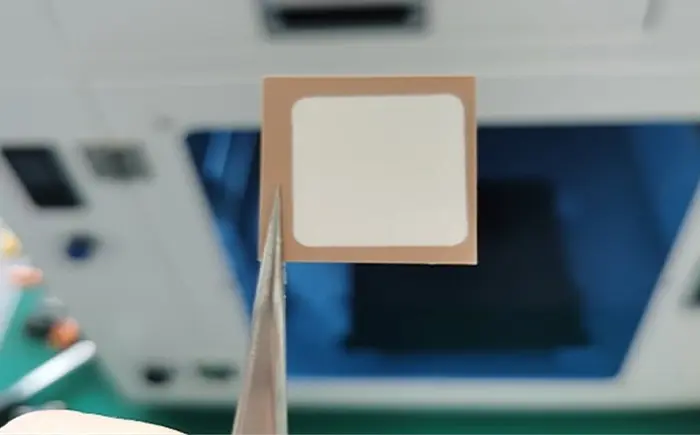

3. Dry film thickness: 20nm-100um (related to solution substrate)

4. Input voltage: 220V±10%,50-60Hz

5. Solution conversion rate: ≥ 95%, utilization rate is several times that of traditional two fluid pressure nozzles

6. Atomized particle size: The average value is 5-50 μ m, mainly depending on the nozzle frequency. The higher the frequency, the smaller the particles

7. Nozzle frequency: can be equipped with multiple nozzle systems ranging from 20-200KHz

-

Optional Configuration

1. Ultrasonic nano dispersion system: Ultrasonic nano particle dispersion system can be installed in various injection pumps and is often used as an important auxiliary accessory in precision spraying systems.

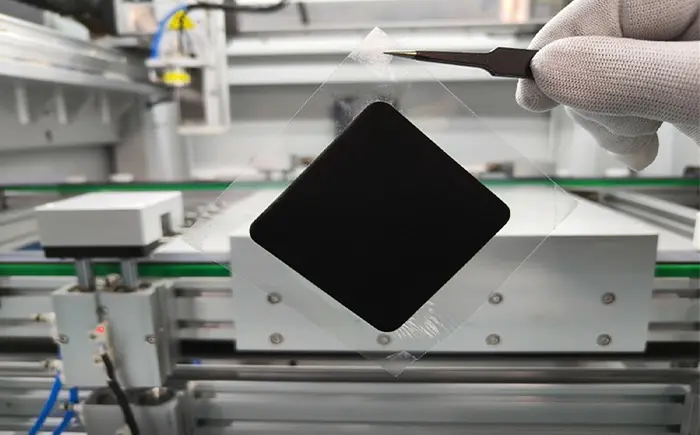

2. Heating vacuum adsorption platform: There are mainly aluminum alloy porous structures and honeycomb ceramic structures. The former is made of aluminum alloy material, with a surface hard oxidation treatment, high flatness, and high thermal efficiency. The latter is developed as a thin film substrate, greatly reducing the defect of small hole collapse.

3. Nozzle alignment device: laser alignment is used.

We can also customize other configurations according to your needs.

Product Application

1. Automotive industry

Application: Introducing ultrasonic online spraying system for vehicle body spraying,result:

The utilization rate of paint has increased by 30%.

After spraying, the surface becomes smoother, reducing the time and cost of subsequent processing.

The production efficiency has increased by 20%.

2. Electronic products

Application: Ultrasonic spraying technology is used for coating the outer shell of mobile phones result:

Achieved uniform coating thickness and enhanced appearance quality.

Reduced the coating defect rate and enhanced the market competitiveness of the product.

3. Household appliances

Application: Use ultrasonic spraying technology for spraying refrigerator shells result:

Improved the adhesion and durability of the coating.

The cleaning and maintenance costs have been reduced by 15%.

4. Medical devices

Application: Ultrasonic spraying technology is used to treat the surface of medical equipment with antibacterial coatings result:

Improved the antibacterial performance of the equipment and met medical standards.

Reduced the risk of pollution during the production process.

5. Aerospace

Application: Ultrasonic spraying technology is used for lightweight and corrosion-resistant coating of aircraft components result:

Implemented a lighter coating and reduced overall weight.

Improved the durability and safety of the components.