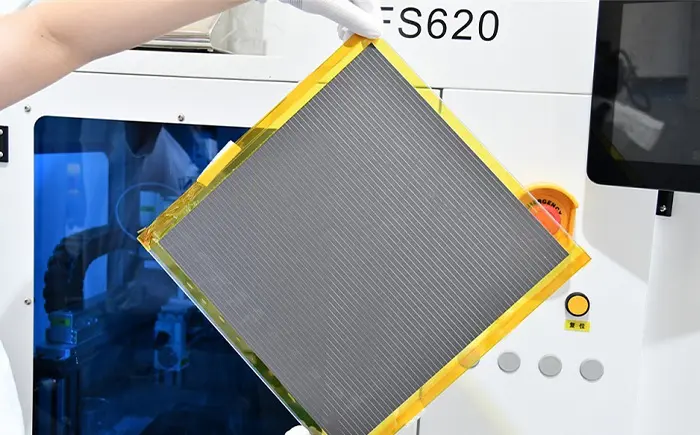

Benchtop Ultrasonic Spray Coating System Basic Type FS310

Advantage

Product Configuration

-

Conventional Arrangement

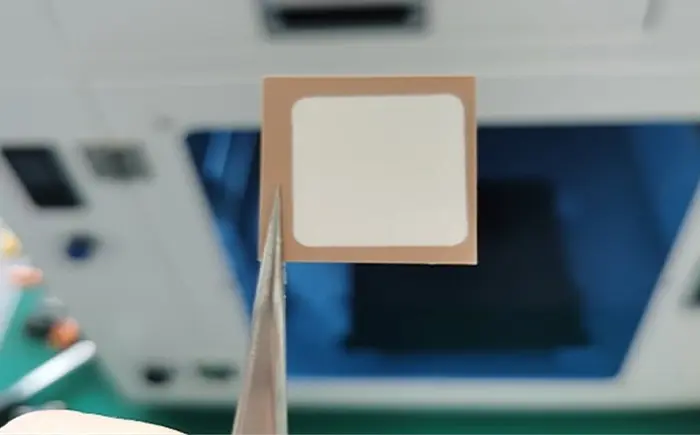

1. Ultrasonic nozzle: FUNSONIC has developed and produced dozens of ultrasonic nozzles, which can be suitable for various working conditions and film thickness requirements.

2. Nozzle frequency: 20Khz, 25Khz, 30Khz, 40Khz, 50Khz,60Khz, 100Khz, 110Khz, 120Khz, 180Khz, 200Khz or Customized

3. Ultrasonic spraying electrical box: Utilizing the principle of ultrasonic atomization to achieve efficient and uniform coating, it is widely used for surface coating.

4. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

5. Motion system: The XYZ three axes all use stepper motors, and the module adopts a fully enclosed linear screw module, significantly improving its service life

6. Operating System: Equipped with FUNSONIC's specially developed control system for ultrasonic spraying, PLC control, and full-color touch screen

-

Optional Configuration

1. Ultrasonic dispersion system: 40Khz 100w FUNSONIC ultrasonic dispersion system specially developed for embedded syringes

2. Heating vacuum adsorption platform: Improved on the basis of ordinary heating platforms, mainly including aluminum alloy porous structures and honeycomb ceramic structures as substrates

3. Optional servo motor

4. Nozzle alignment device: Use laser positioning to quickly align the material spraying position.

5. Default exhaust fan: customizable to connect with laboratory exhaust pipe structure

We can also customize other configurations according to your needs.

Coating Influence Factor

Ultrasonic waves with different frequencies will affect the atomization effect of spray and the dispersion state of particles. Usually, higher frequencies can provide better atomization effects.

2. Properties of spraying liquid:

Physical properties such as viscosity, surface tension and density of liquid will affect the formation of spray and the uniformity of spraying.

3. Spray parameters:

Spray speed, spray distance, and spray angle all affect the uniformity and thickness of the coating.

4. Surface characteristics of the substrate:

The roughness, surface energy, and chemical properties of the substrate can affect the adhesion and dispersion.