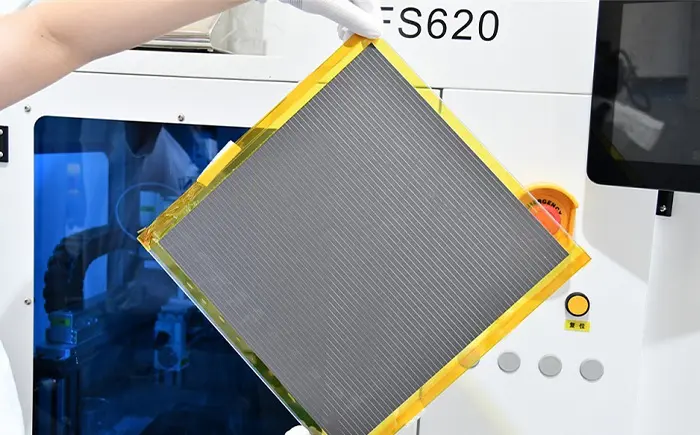

Benchtop Ultrasonic High Temperature Coating System FS620H

Advantage

Product Configuration

-

Conventional Arrangement

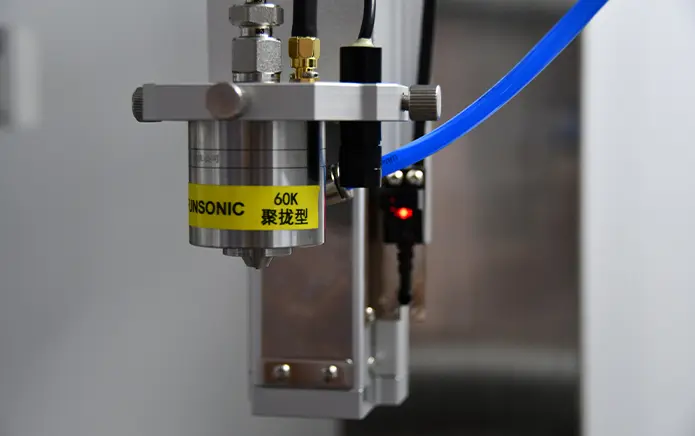

1. FUNSONIC Customized Ultrasonic nozzle: 20-200Khz

2. Ultrasonic power supply: Digital

3. Solution supply system: biological grade sampler, liquid supply accuracy of 0.1 μ L/min

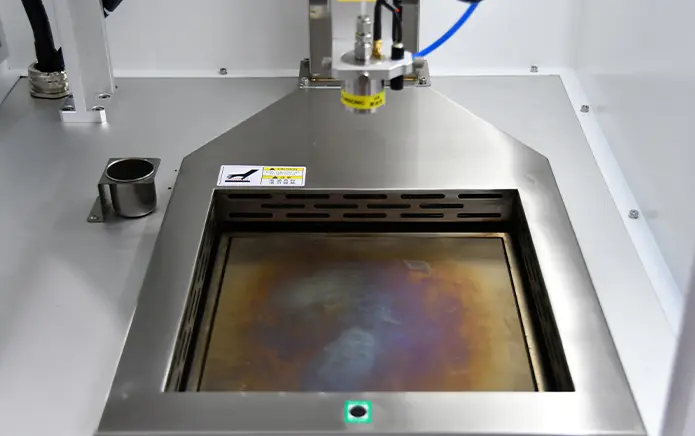

4. Sports system: XYZ three-axis imported servo motor

5. Operating System: Atomization control system, PLC control, and LCD screen

-

Optional Configuration

1. Ultrasonic dispersion supply system: By embedding a 40Khz high-frequency ultrasonic transducer into the injector, various nano suspensions can be effectively dispersed and transported, reducing the sedimentation phenomenon of the spray solution and greatly improving the uniformity of the film layer

2. High precision heating platform: The temperature control accuracy is ± 0.1 ℃, and multiple temperature settings can be made. The heating temperature can reach 500 ℃.

3. Nozzle alignment device: Use laser alignment to quickly align the material spraying position.

We can also customize other configurations according to your needs.

Product Application

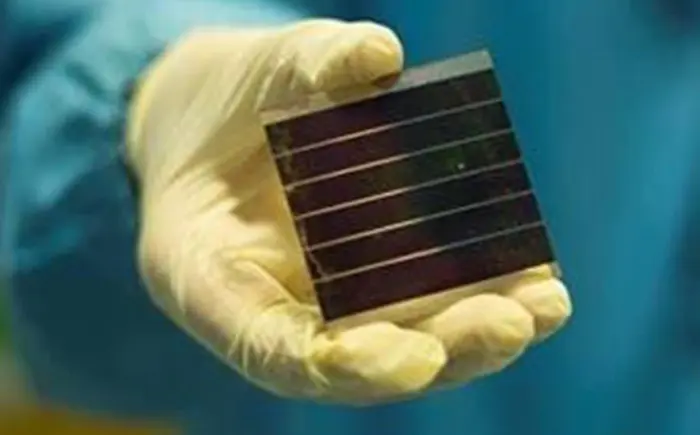

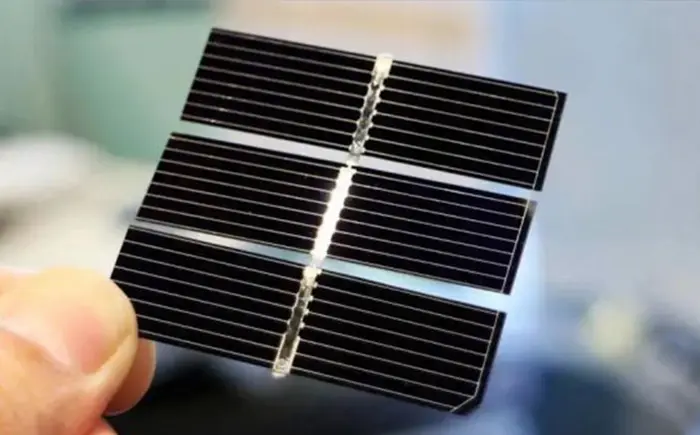

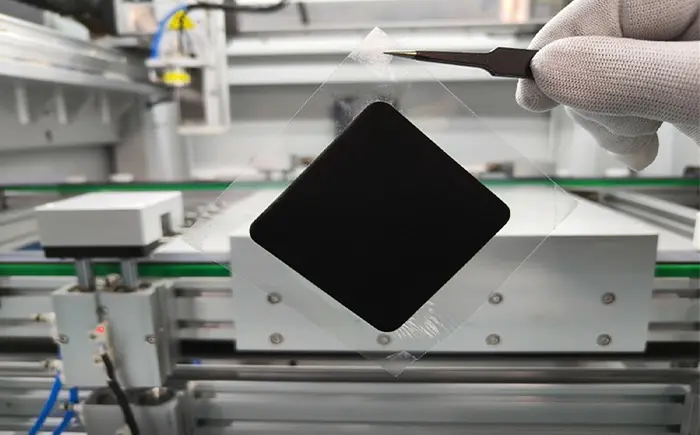

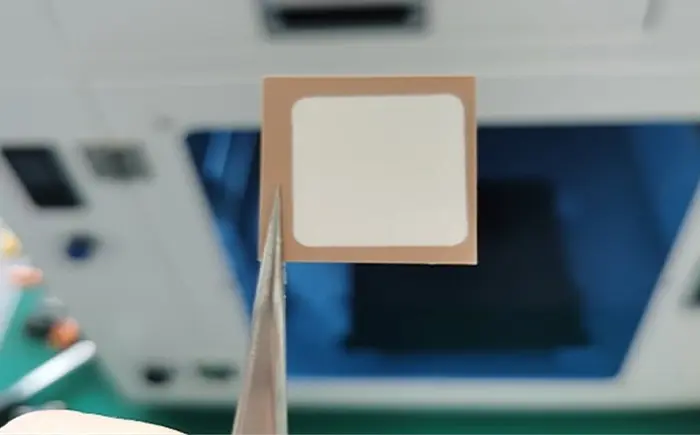

1.Perovskite solar cells

By optimizing the spraying parameters, the energy conversion efficiency of the battery has been successfully improved, reaching over 20%. The uniformity and stability of the film have been significantly improved, extending the service life of the battery.

2. Optical glass coating

Using an ultrasonic sprayer to spray perovskite coatings on optical components to enhance their transparency and wear resistance. The equipment controls the thickness and uniformity of the coating in high temperature environments, increasing light transmittance by 15% while enhancing scratch resistance and reducing maintenance costs.

3. Catalyst synthesis

By adjusting the spraying and pyrolysis conditions, the structure of the catalyst was optimized, the catalytic activity was improved, and the reaction efficiency was increased by 30%. The catalyst maintained stability at high temperatures and extended its service life.

4. Electronic device packaging

High tech companies use this spraying machine to spray a perovskite protective layer on the surface of electronic devices to prevent oxidation and corrosion. The uniformity and adhesion of the protective layer are greatly improved, enhancing the environmental resistance of electronic devices. The overall reliability and lifespan of the product have significantly improved.