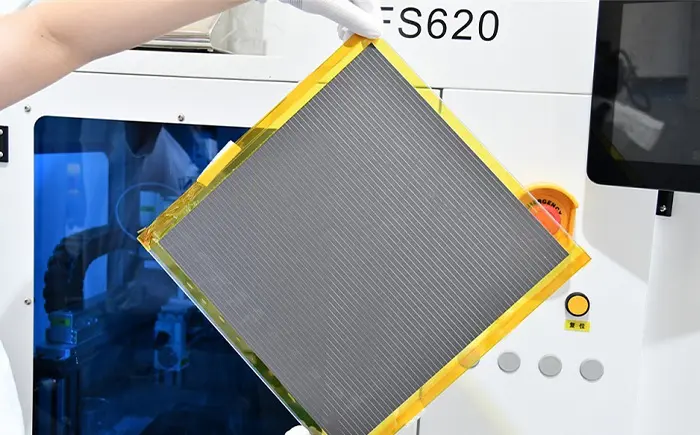

Benchtop Constant Flow Ultrasonic Coating System FS620C

Advantage

Product Configuration

-

Conventional Arrangement

1. Ultrasound nozzle: 20-200Khz

2. Material of Nozzle: Titanium

3. Ultrasonic Driver: fully intelligent frequency tracking

4. Liquid supply equipment: Constant flow pumping type+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

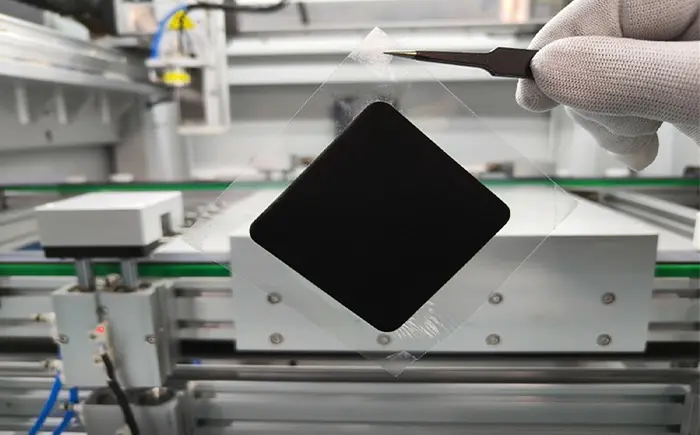

5. Sports system: XYZ three-axis imported servo motor+fully enclosed precision screw module

6. Operating System: FUNSONIC independently developed a spraying control system, PLC control, and full-color touch screen

-

Optional Configuration

1. Ultrasonic dispersion injection system: 40Khz 100w ultrasonic dispersion

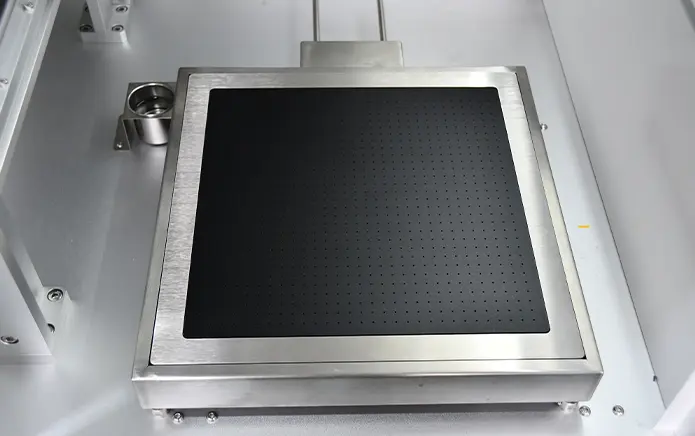

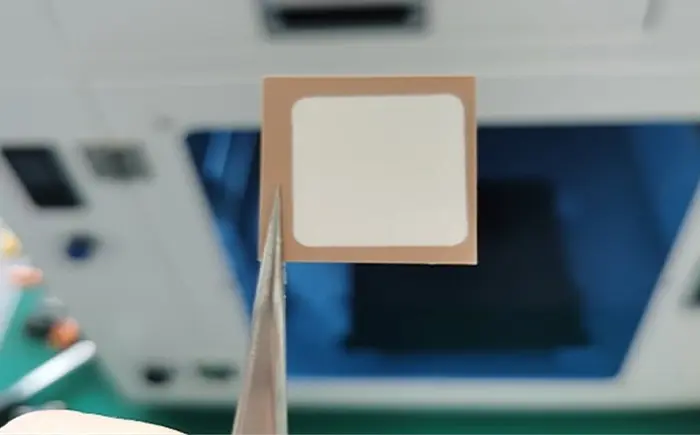

2. Heating platform: using aviation aluminum porous platform or precision microporous ceramic platform, precise temperature control of 200 ℃ (higher heating temperature can be customized)

3. Vacuum adsorption platform: Internal installation of vacuum generator to achieve vacuum negative pressure

4. Nozzle alignment device: using laser alignment to quickly align the material spraying position.

We can also customize other configurations according to your needs.