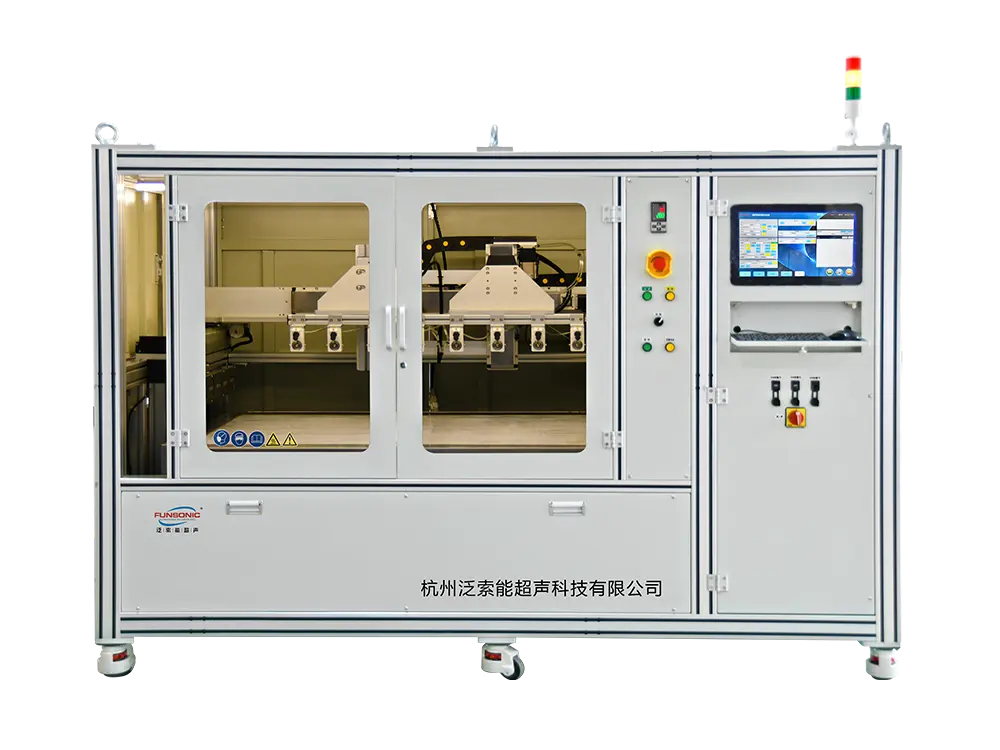

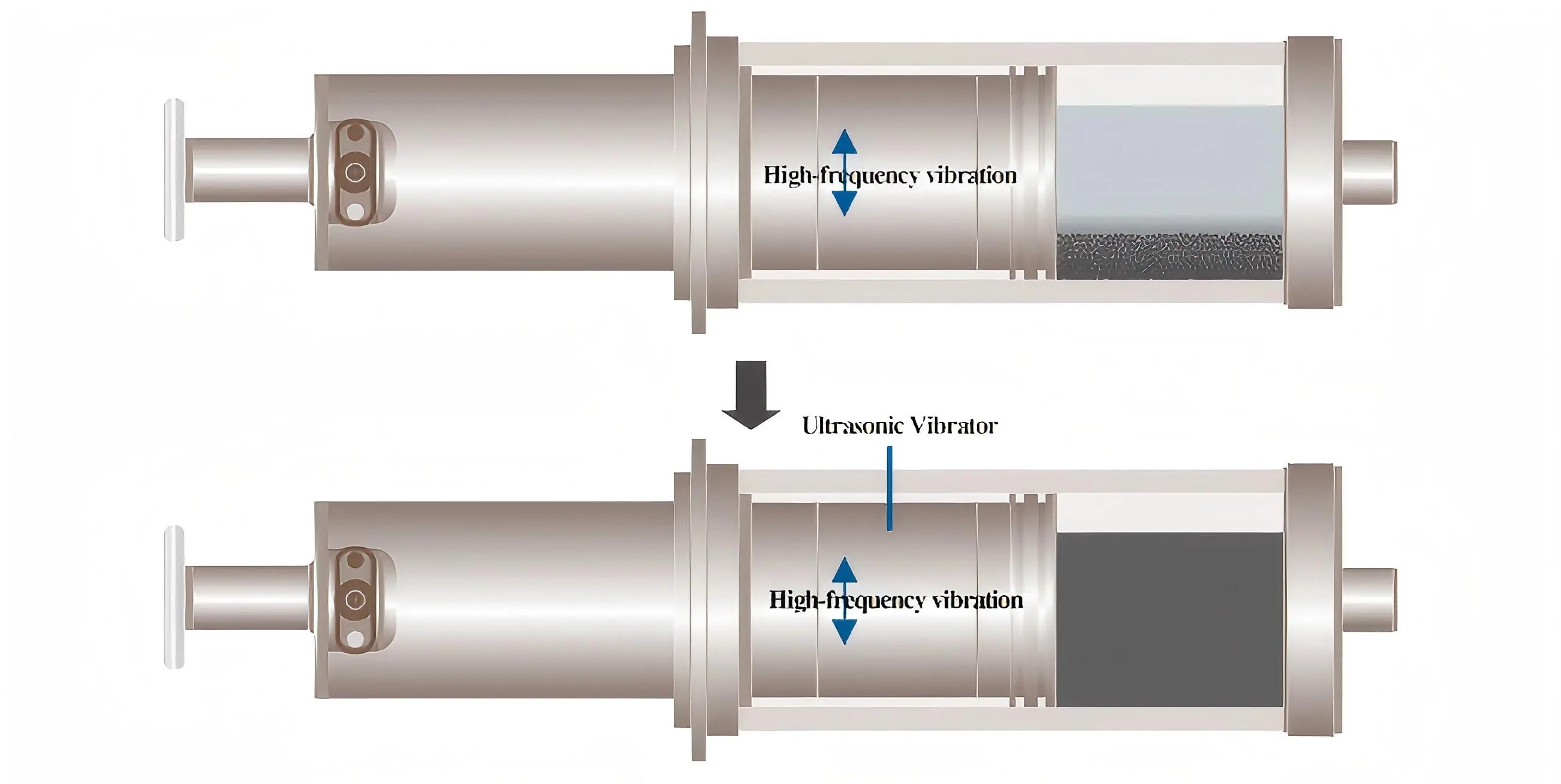

Automatic Flow Injection Pump with Ultrasonic Dispersion FSLAB02

Main Features:

1. Strong application flexibility and programmability

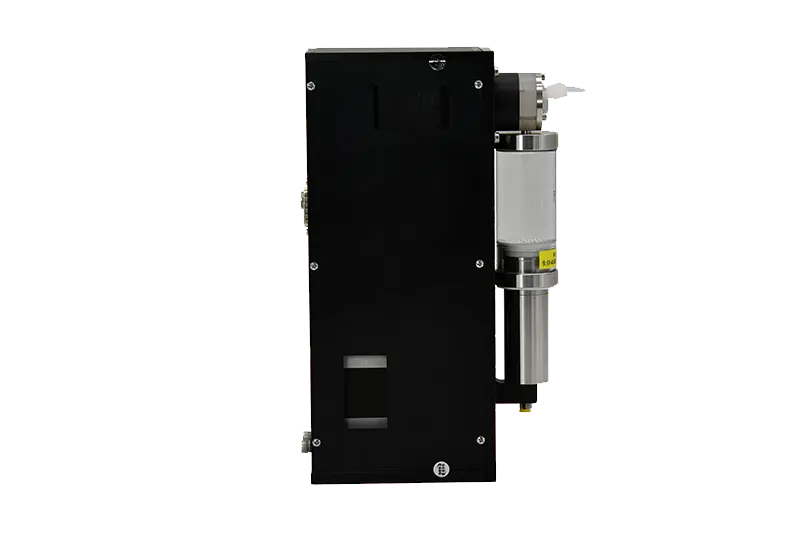

2. Implement automatic liquid extraction

3. Real and reliable performance, achieving planned maintenance and replacement of injectors

4. Simple integration method to achieve synchronization with other external devices

5. Widely applicable to various sizes of syringes and directional valves

0102030405

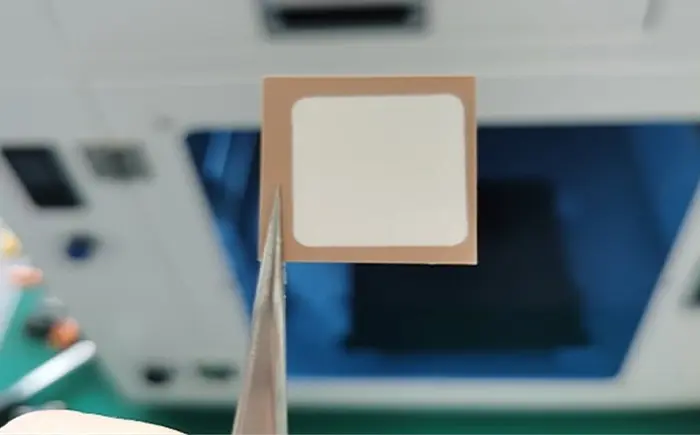

Demonstration

010203