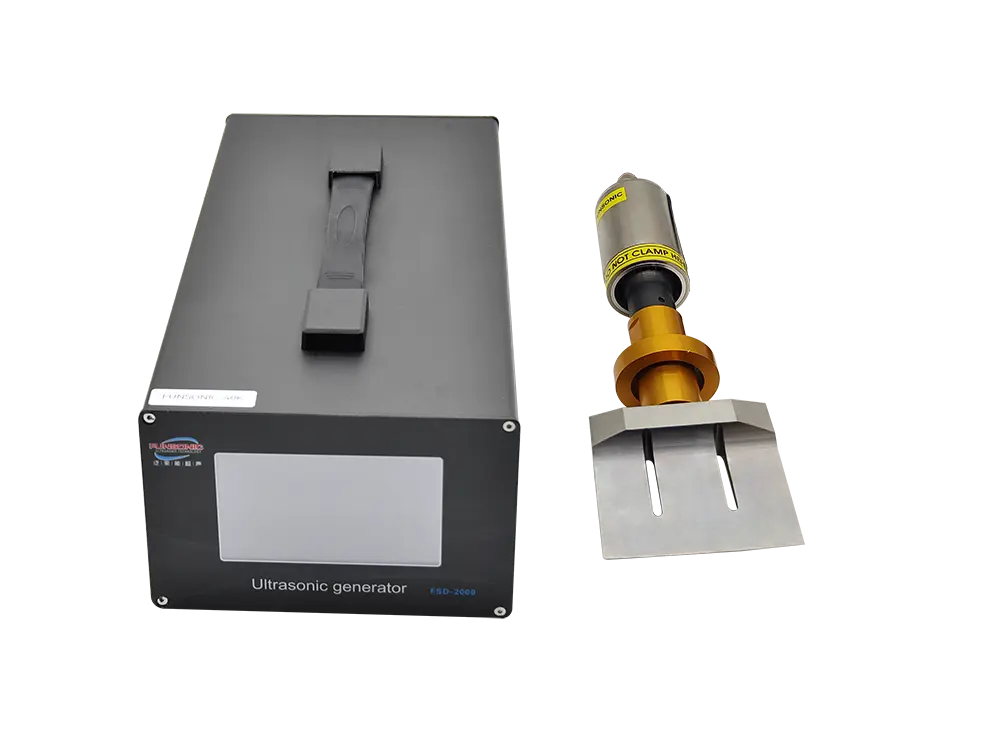

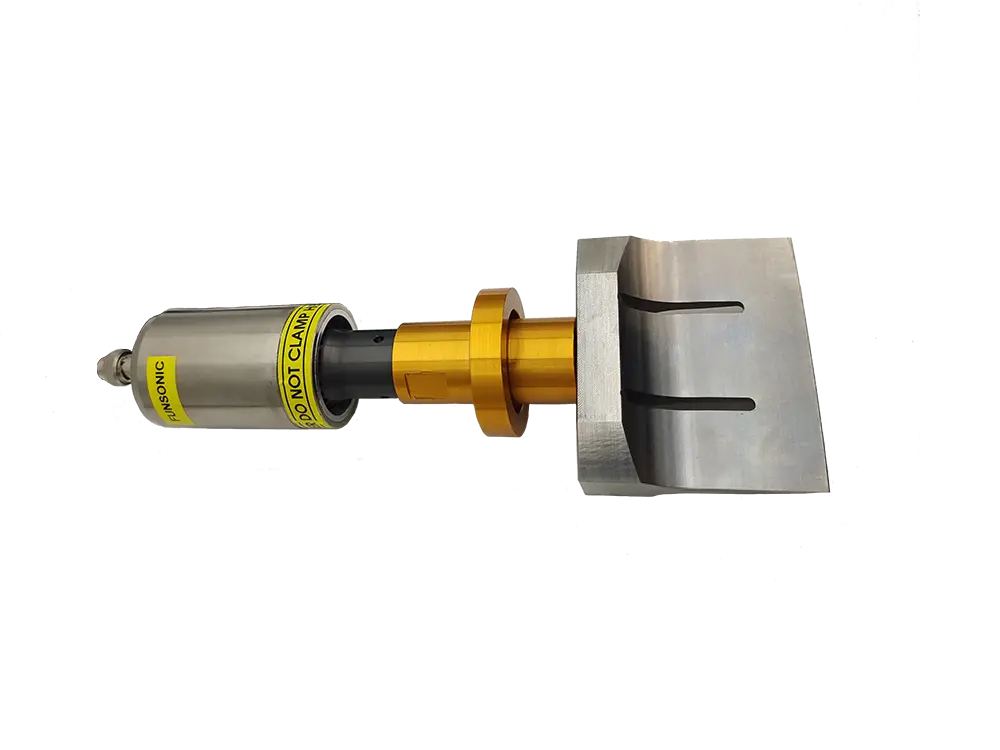

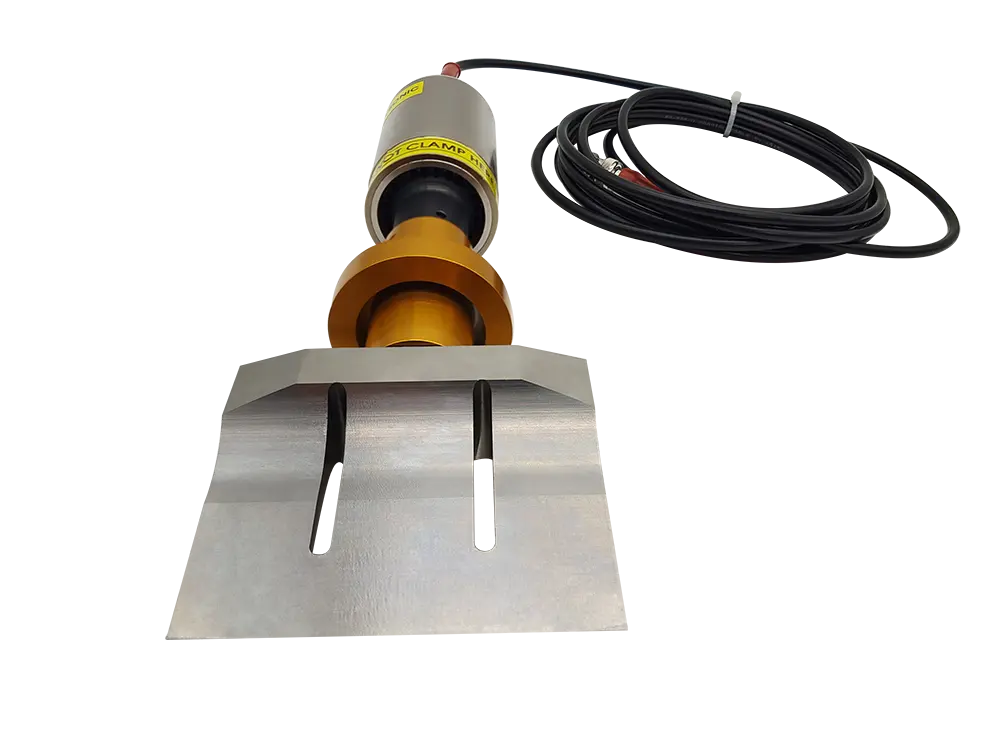

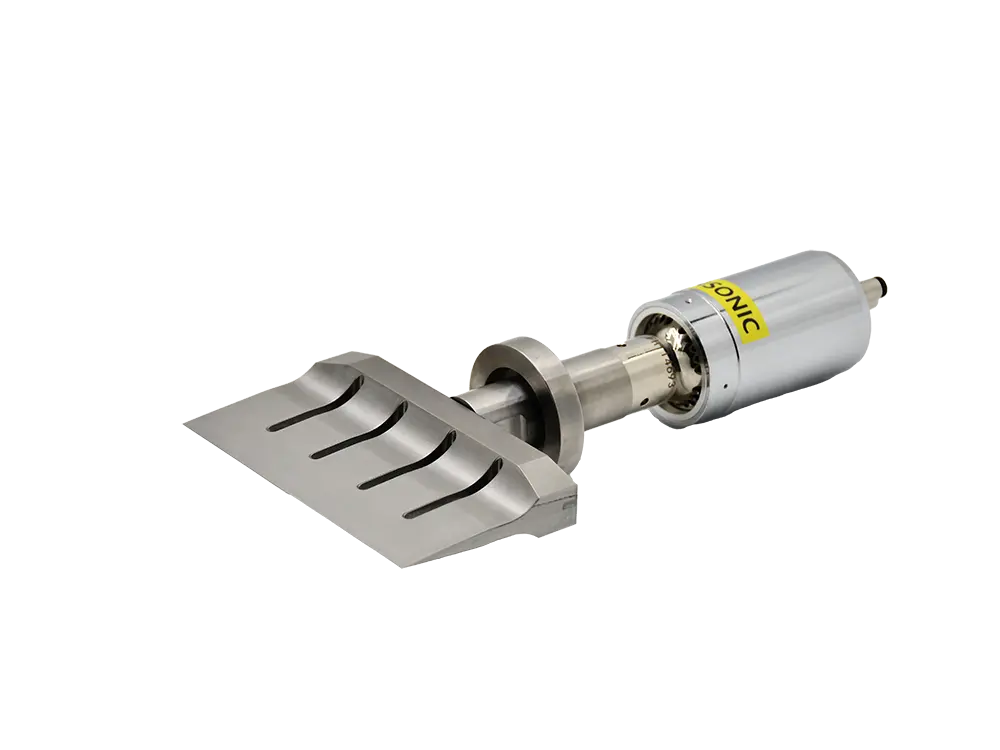

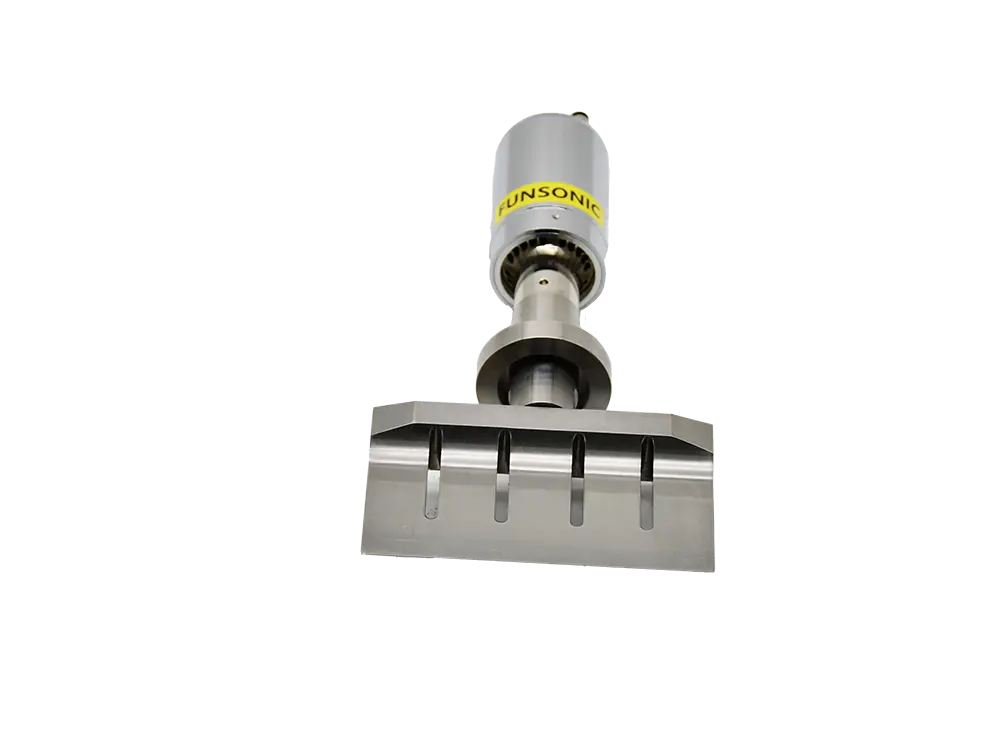

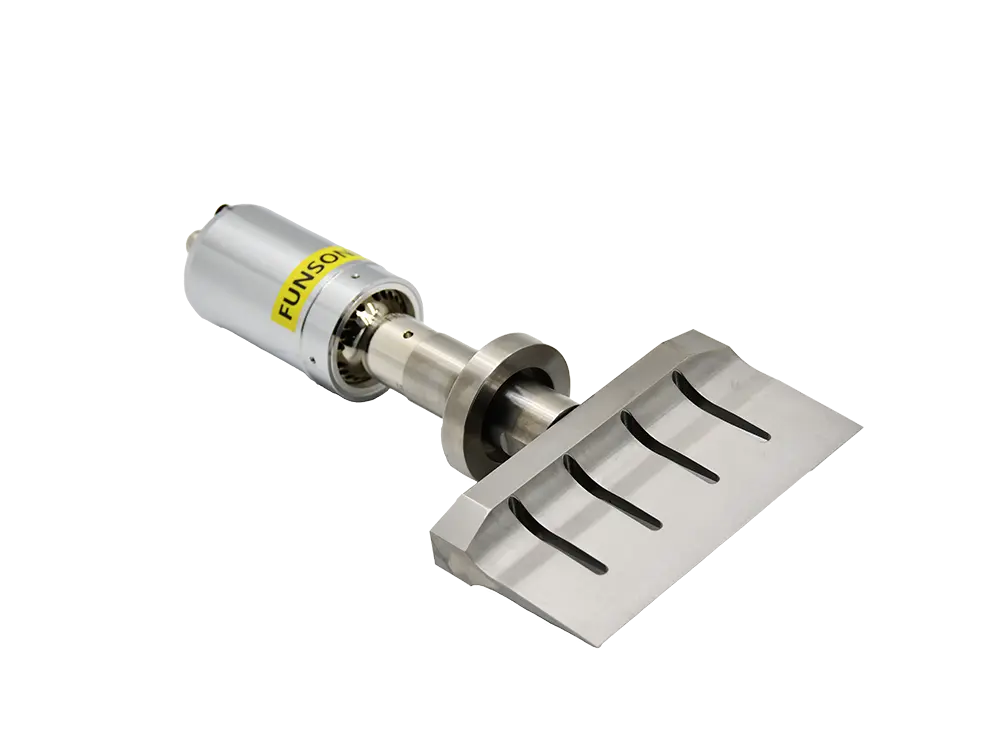

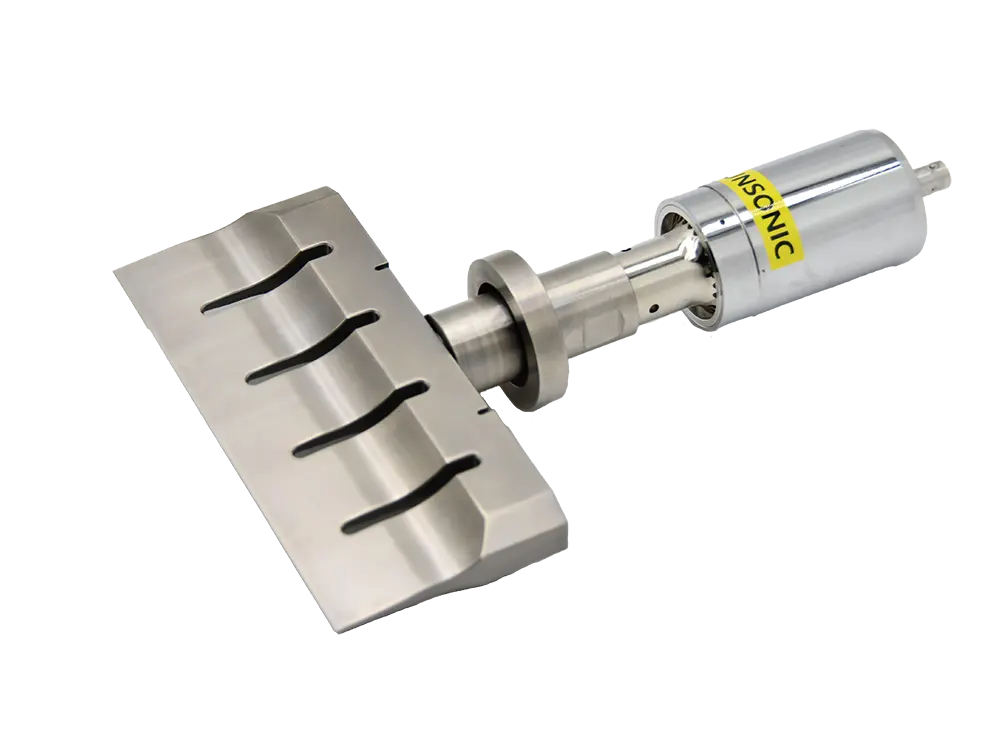

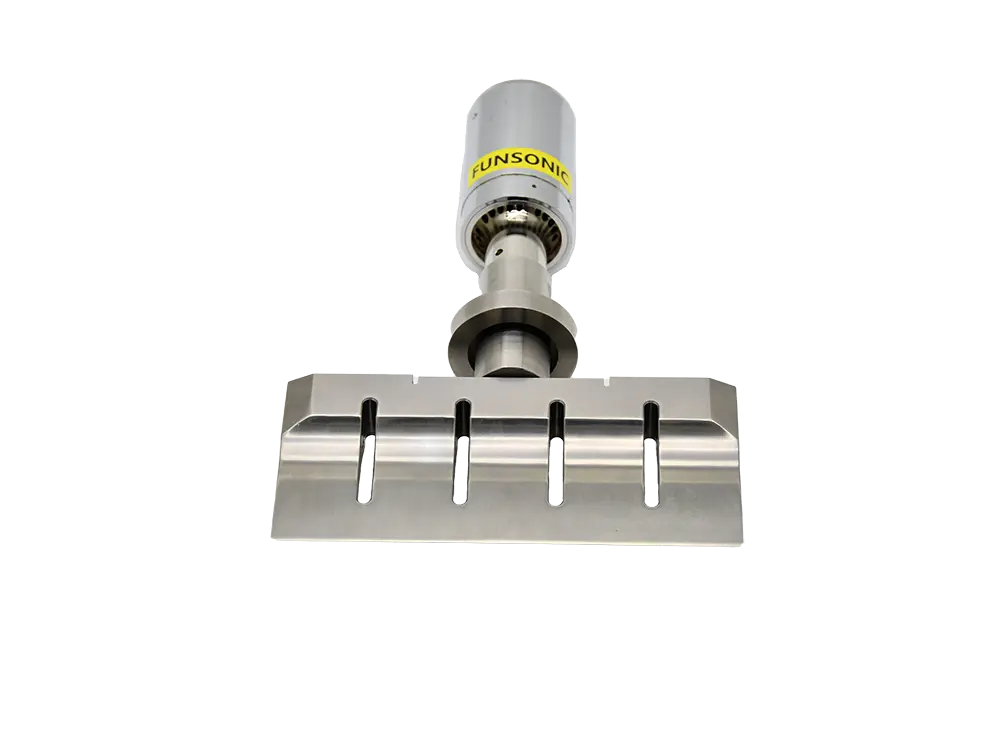

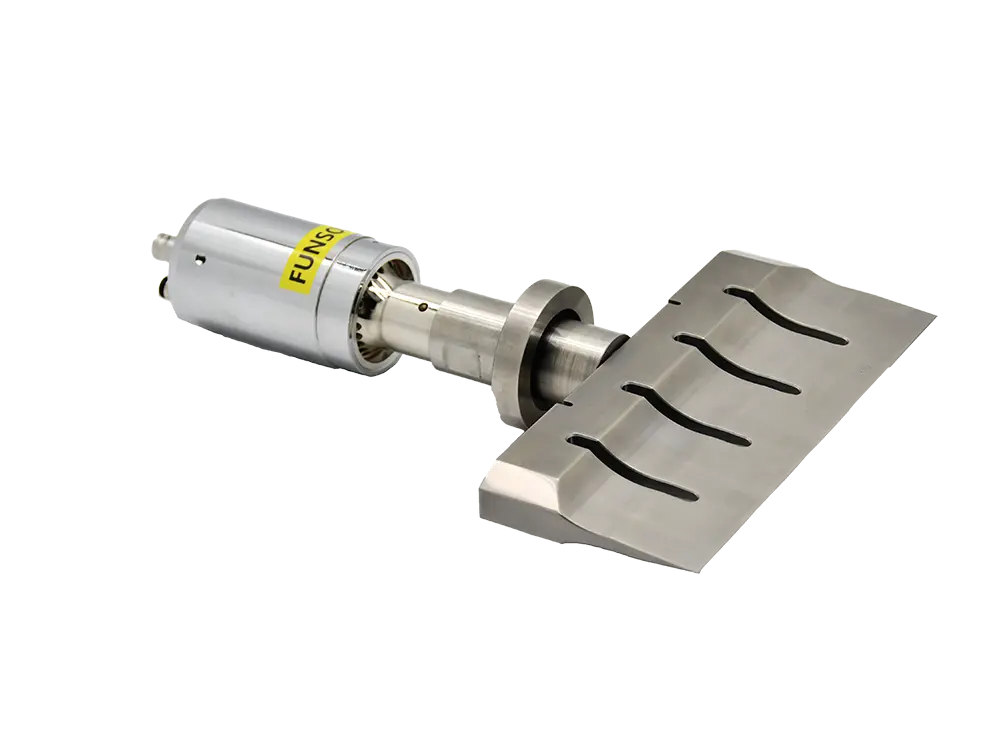

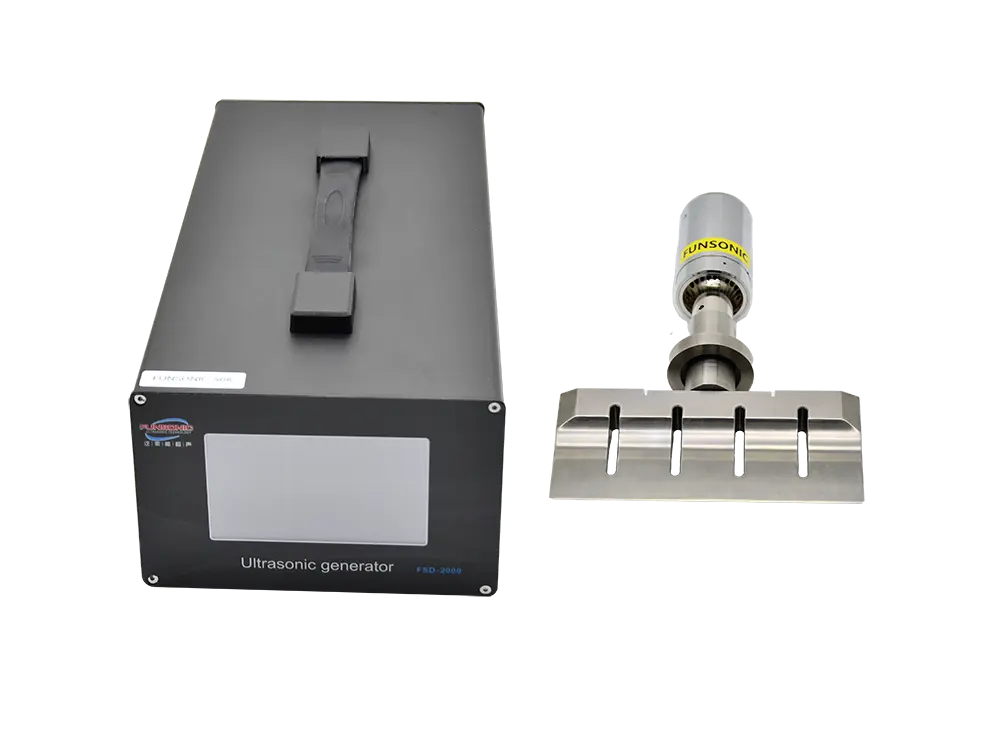

40Khz Ultrasonic Rubber Cutting Machine

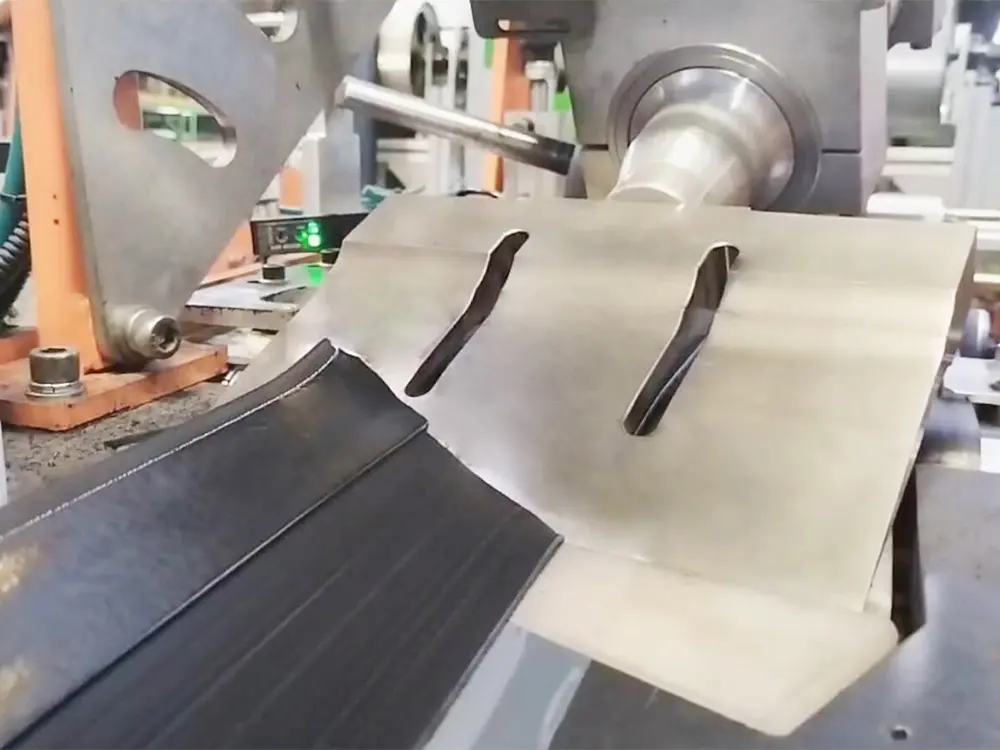

3. Radial tires:

The internal structure of radial tires is more complex, but ultrasonic cutting can still be easily processed.

The cutting surface is smooth and tidy, without any defects such as tearing.

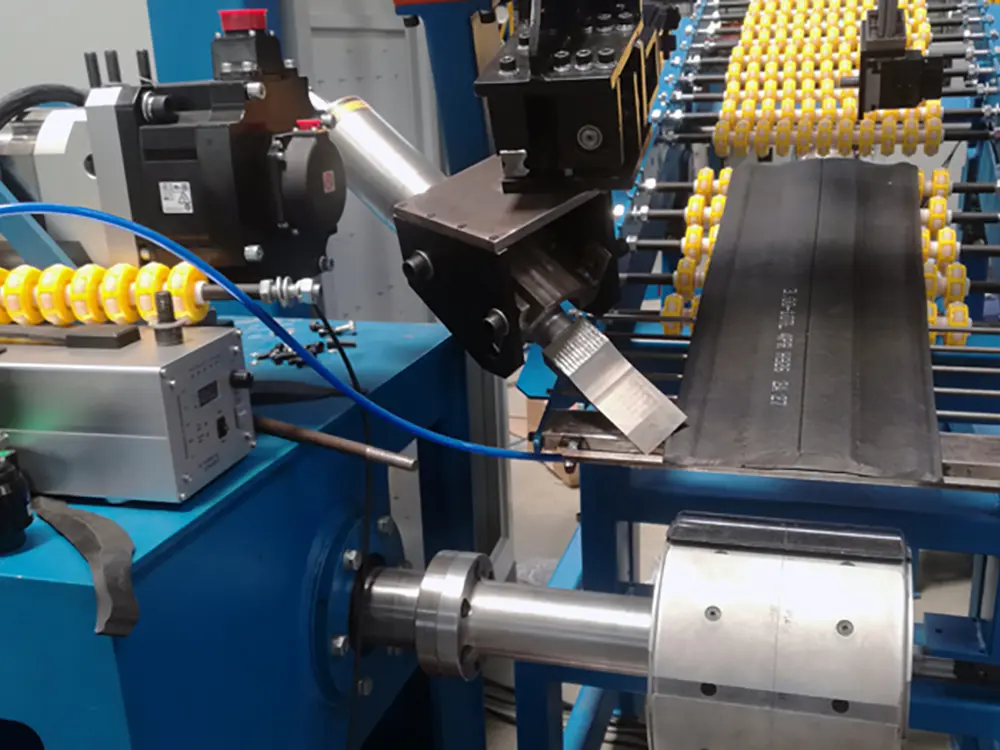

4. Construction machinery tires:

These types of tires are usually thicker and more durable, but ultrasonic cutting can still cut efficiently.

The cutting process is clean and tidy, without producing a large amount of debris.

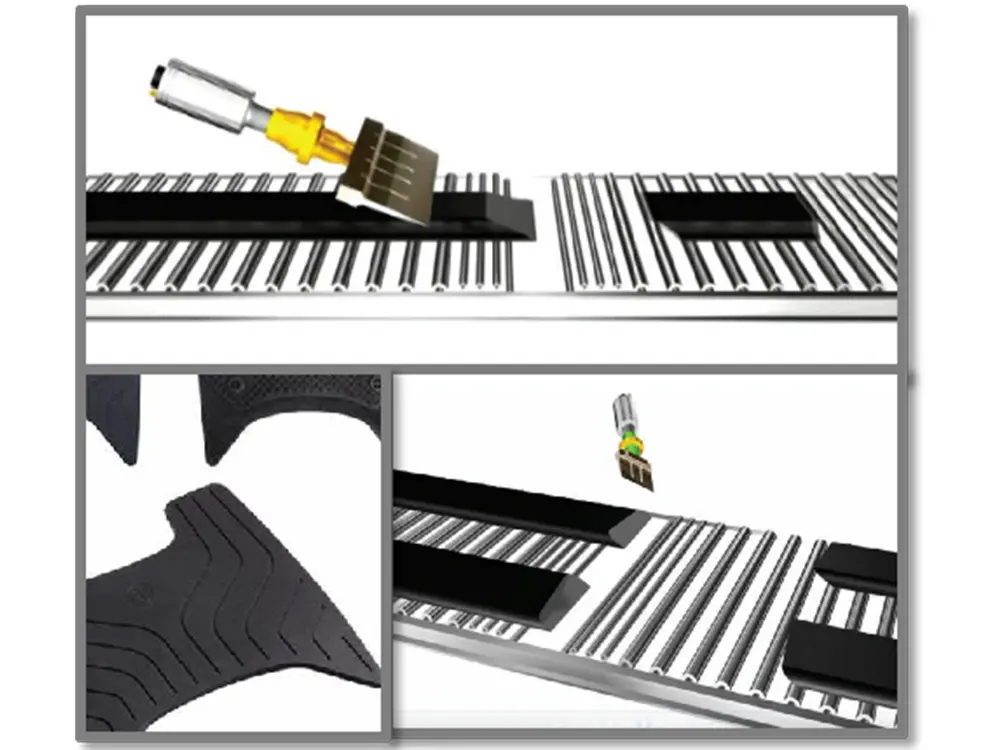

5. Various composite tires:

Tires containing composite materials such as nylon and aramid can also be well processed by ultrasonic cutting.

The cutting effect is neat and there will be no burrs, debris or other problems.

Demonstration

0102