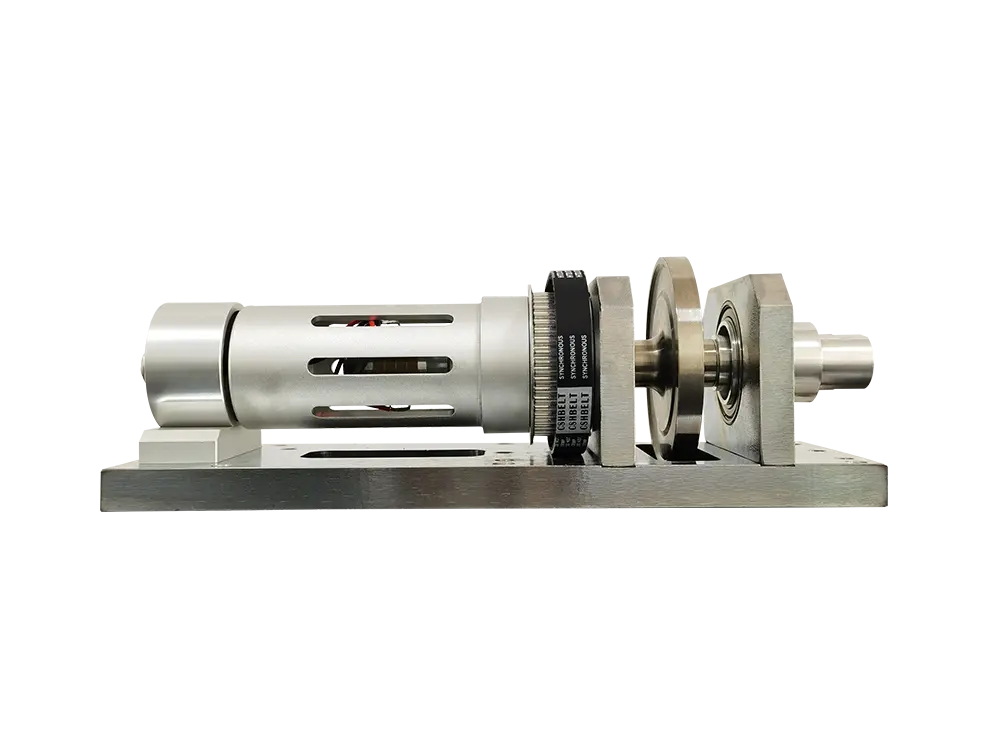

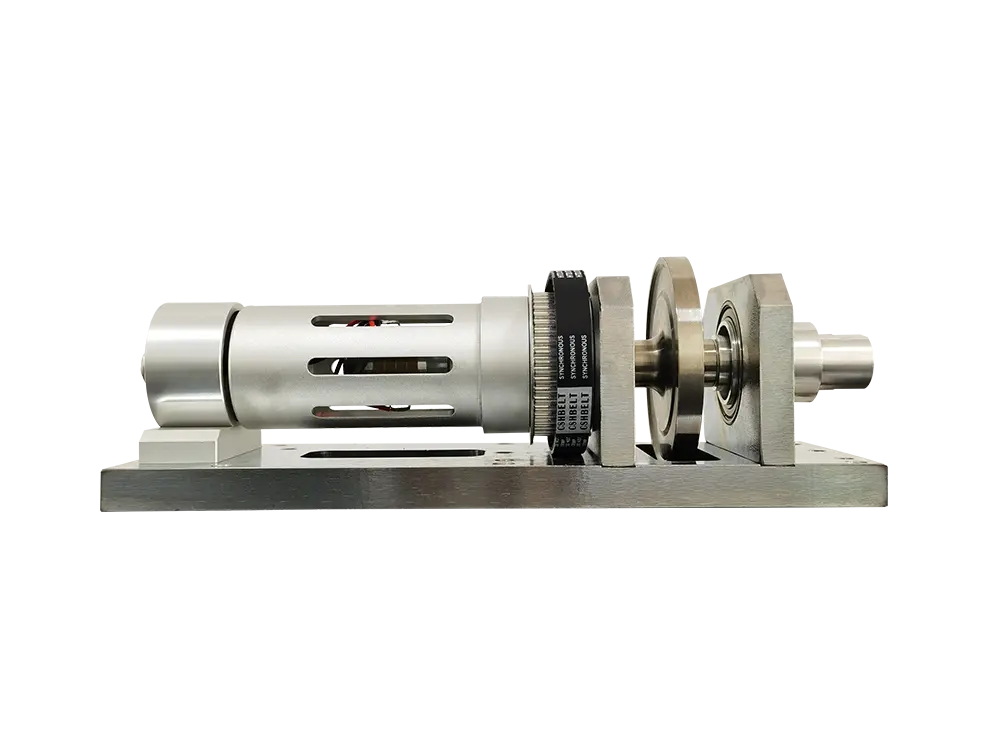

Short Description

Ultrasonic seamless sewing technology is used for sewing and cutting cloth, which is the latest technological achievement in the world. Pansoneng Company keeps up with the latest scientific research results abroad and develops the core of ultrasonic seamless sewing machine. This is the core component of ultrasonic seamless sewing machine, which completely solves the inherent problem of the original ultrasonic longitudinal vibration technology, that is, the movement direction of the ultrasonic welding head is inconsistent with the movement direction of the cloth. The accuracy of ultrasonic cloth sewing has been greatly improved, which makes the wide application of ultrasonic technology in the field of clothing sewing possible. Ultrasonic seamless sewing has the characteristics of fast welding speed, high strength, beautiful weld, good sealing performance, low energy consumption, easy operation, etc., which is the development direction of sewing machines.