Short Description

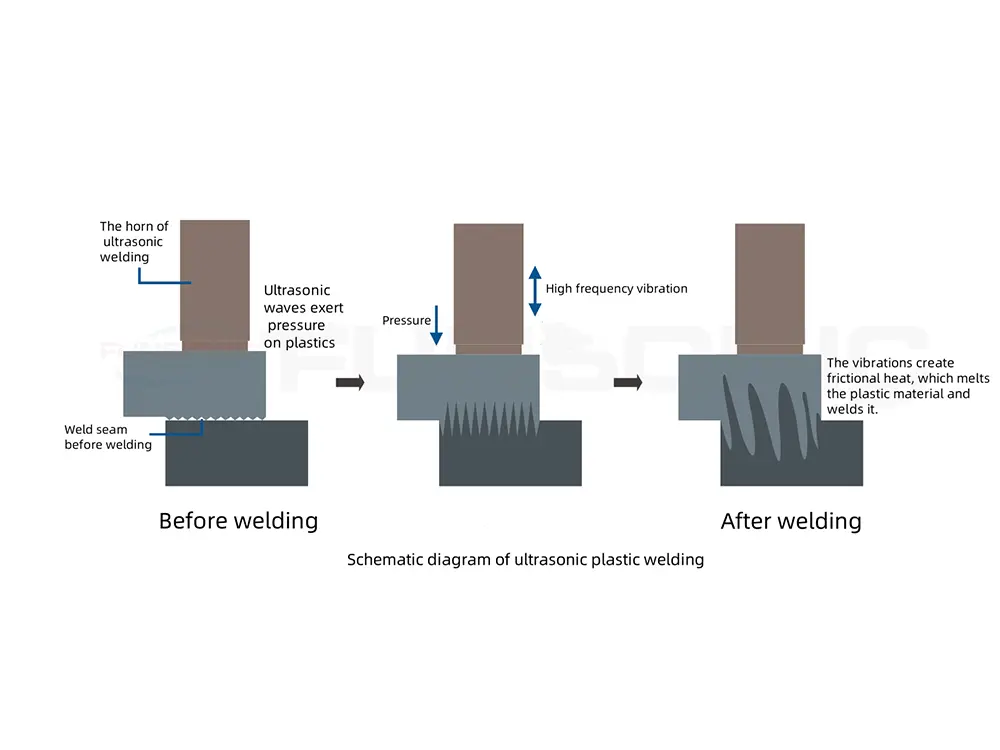

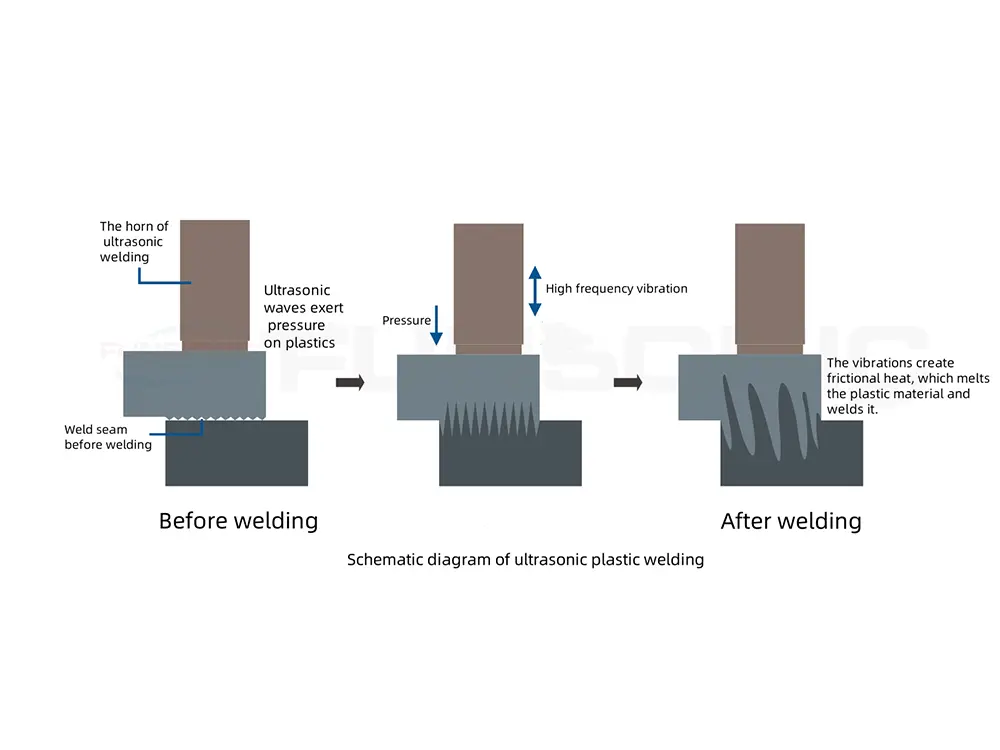

Plastics are undoubtedly the most used materials in almost all fields today, and the application fields of plastics also confirm the widespread use of ultrasonic technology. Ultrasonic welding is the fastest, most accurate, most economical and effective welding method for thermoplastic materials. It uses ultrasonic energy to generate local high temperature in the welding area, so that the surface of the thermoplastic material melts rapidly, and after applying a certain pressure, it is a welding device that fuses them together. Ultrasonic welding is carried out in a short time, so it is not comparable to the method using adhesives. Due to the strong bonding force and clean welding parts, it can reduce costs and improve productivity and quality.