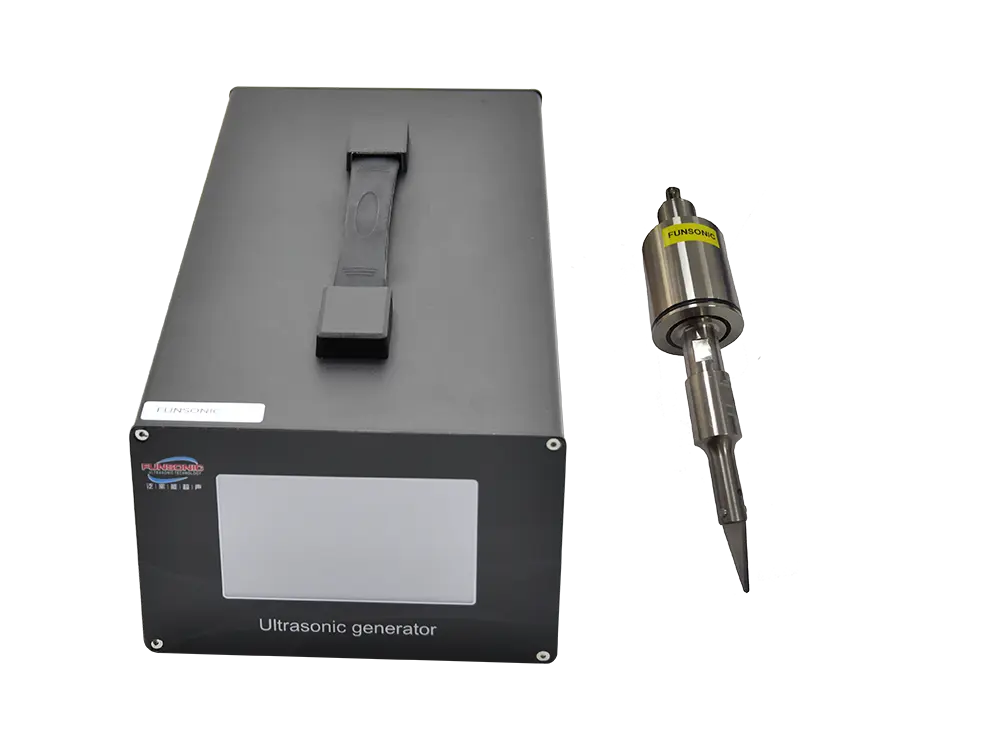

35Khz Ultrasonic Machine Mounted Cutting Machine

3. Textile industry

Fabric cutting: Ultrasonic cutting can prevent the edges of the fabric from scattering and improve cutting quality.

Non woven fabric: used for cutting non-woven fabric materials, suitable for the production of medical and hygiene products.

4. Electronic industry

Insulation material cutting: suitable for cutting insulation materials to ensure the safety of electronic components.

Precision component machining: used for high-precision cutting of electronic components to meet strict dimensional requirements.

5. Food industry

Food cutting: used for cutting cakes, cheese, and other foods to maintain a neat and aesthetically pleasing cutting surface.

Film packaging: Sealing and cutting in food packaging to ensure the freshness of the food.

6. Composite materials

Aerospace: Used for cutting lightweight composite materials such as carbon fiber and glass fiber, suitable for high-performance applications.

Automobile manufacturing: Cutting complex shapes in the production process of automotive components.