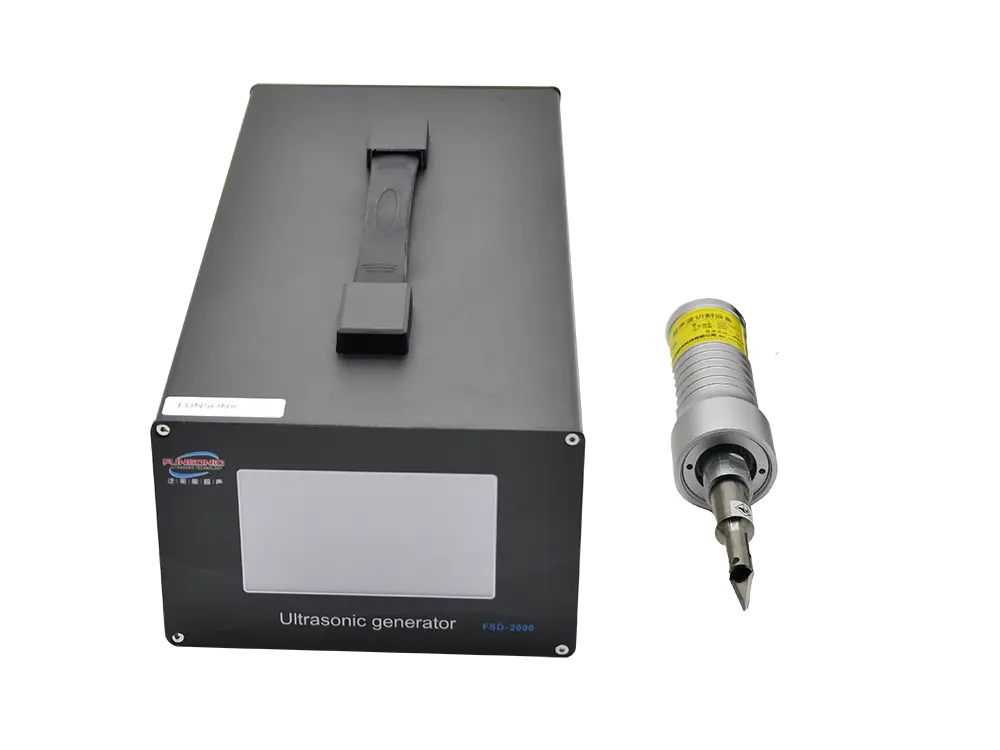

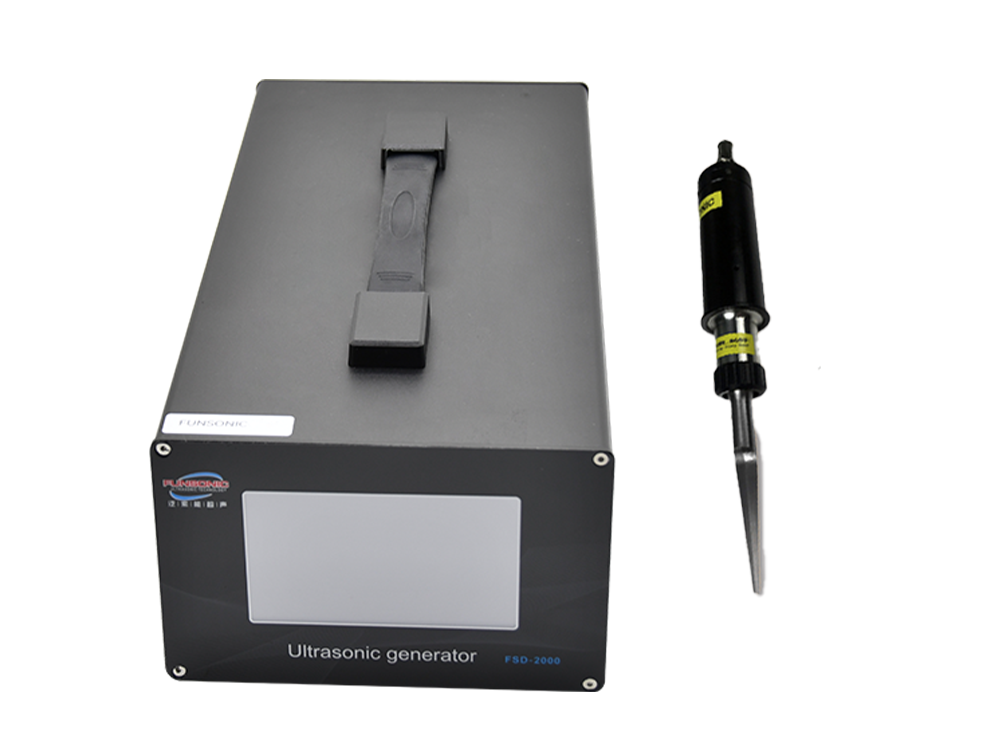

35Khz Ultrasonic Handheld Cutting Machine

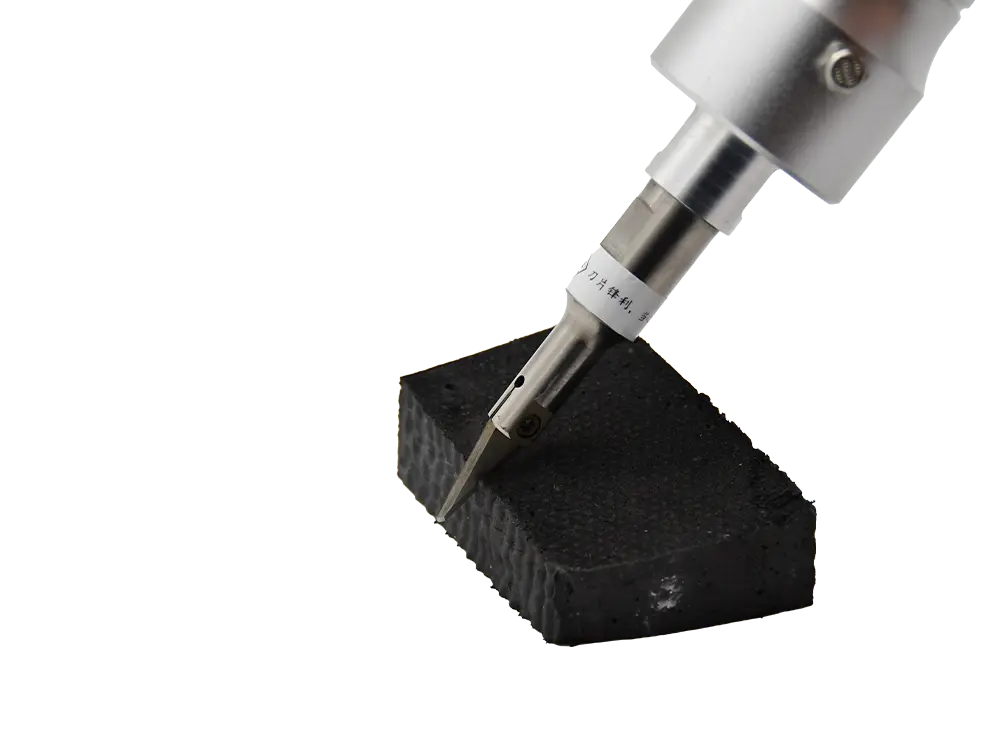

3. Carpet and seat belt webbing cutting

Cutting thick carpets and seat belt webbing materials will not damage them

The cutting edge is clean and free of burrs, which is conducive to subsequent sewing or bonding

4. Cutting of dashboard decorative parts

Capable of accurately cutting decorative parts with various complex shapes

The cutting surface is smooth and does not require further processing

5. Cutting of ceiling lining

Cutting soft synthetic fiber materials will not cause fiber scattering

A flat cutting edge is beneficial for subsequent fixation and bonding