20Khz Ultrasonic Vertical Tinning System

Advantages

◆ Green and environmentally friendly soldering solution

1. Will not emit any harmful chemicals to the environment and human health: No need for soldering flux or soldering flux cleaning process.

2. There is no water pollution or air pollution: no soldering flux is used during soldering, no harmful gas emissions are generated, and no industrial wastewater is produced.

◆ Achieve perfect soldering

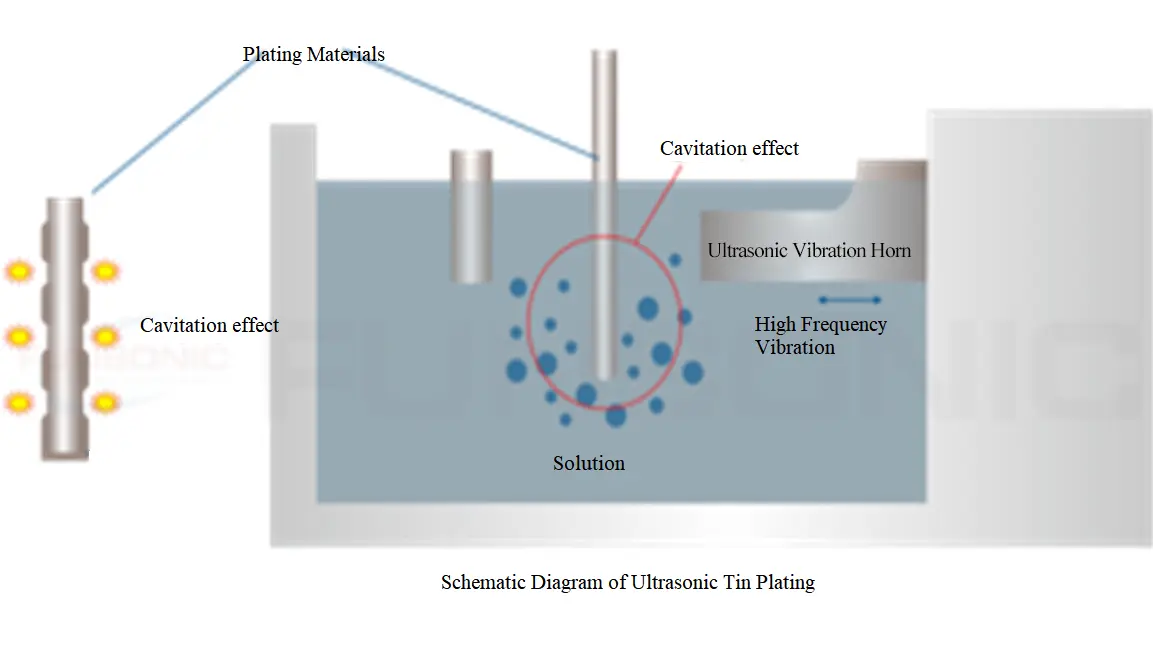

If flux is used during soldering, tiny bubbles will be generated inside the solder, which can lead to quality problems such as cracks over time. However, ultrasonic soldering, without using flux, can penetrate very small gaps due to vibration energy, preventing tiny bubbles from being generated inside the solder and achieving perfect soldering (sealing).

2. Helpless soldering flux ->No welding joint defects caused by strong corrosion of soldering flux.

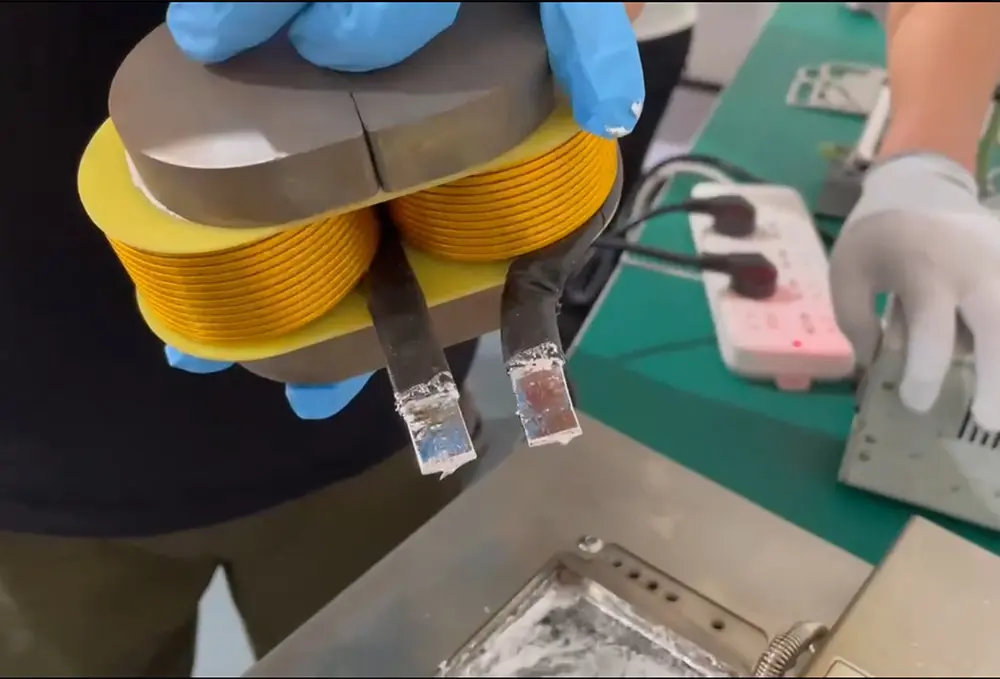

3. By using ultrasonic vibration to allow solder to penetrate small gaps, the welded joint is firm and reliable.

◆ Save production costs and improve production efficiency

Using aluminum wire instead of expensive copper wire can greatly save costs (saving 80%).

2. By not using soldering flux for welding, there is no need for pre-treatment or processes related to soldering flux, which can save equipment and production costs, simplify the soldering process, and improve production efficiency.

◆ Support the development of new materials and products

1. It can successfully weld materials that are difficult to weld, such as glass, ceramics, aluminum, and non-metallic materials that cannot be welded by traditional welding methods, which is helpful for the development of new materials.

2. Suitable for solar cell glass, semiconductor, and ceramic heaters, easy to weld for dual materials (aluminum copper, copper glass, aluminum glass, aluminum ceramic), and helpful for the development of new products.