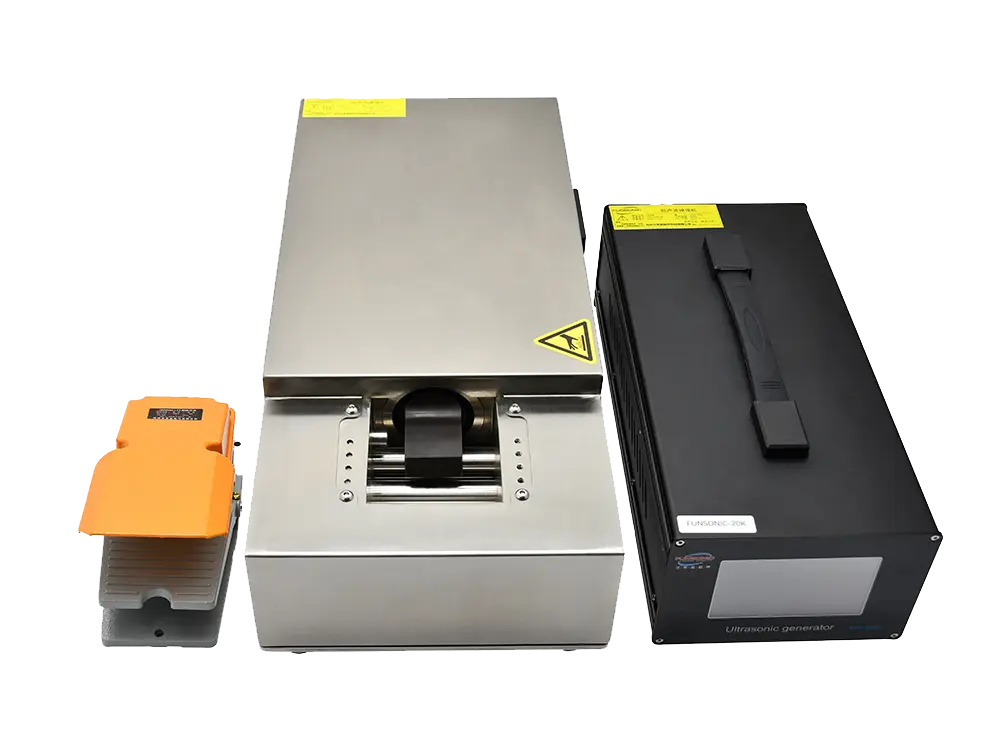

20Khz Ultrasonic Benchtop Tinning System

Advantages

1. Ultrasonic assisted:

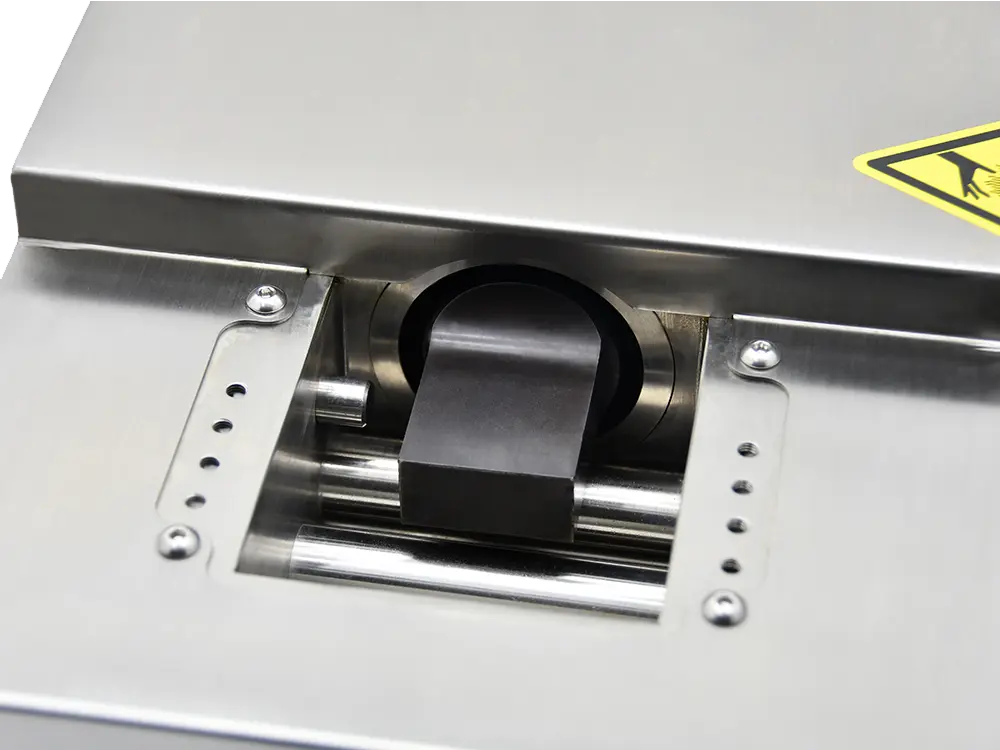

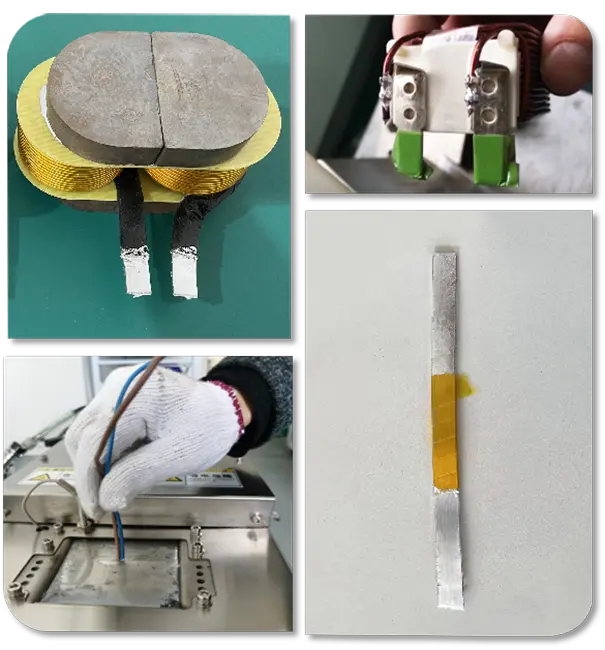

By utilizing the high-frequency vibration of ultrasound, the fluidity and wettability of the tin solution are enhanced, ensuring that tin can fully penetrate into the tiny gaps on the surface of the component.

2. Uniform coating:

The effect of ultrasound can achieve uniform coating of tin layer, avoiding welding defects caused by uneven coating.

3. High efficiency:

Compared to traditional tin dipping methods, ultrasonic tin dipping equipment can significantly improve production efficiency and shorten processing time.

4. Improve welding performance:

By using a uniform tin layer, the reliability and durability of welding are improved, and welding defects are reduced.

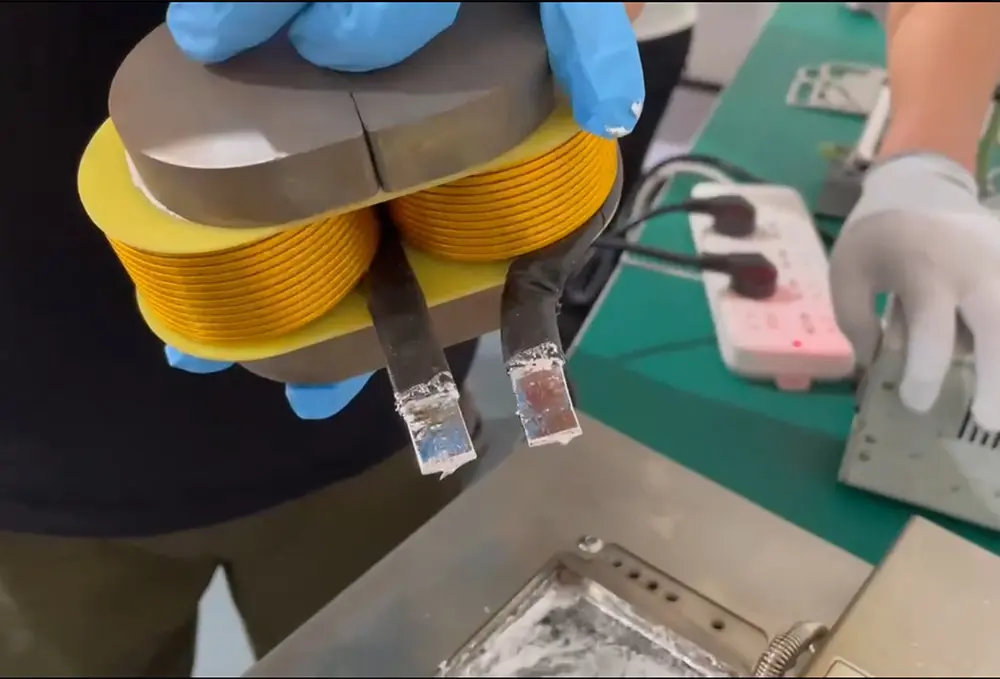

Demonstration

0102