7

YEARS OF EXPERIENCE

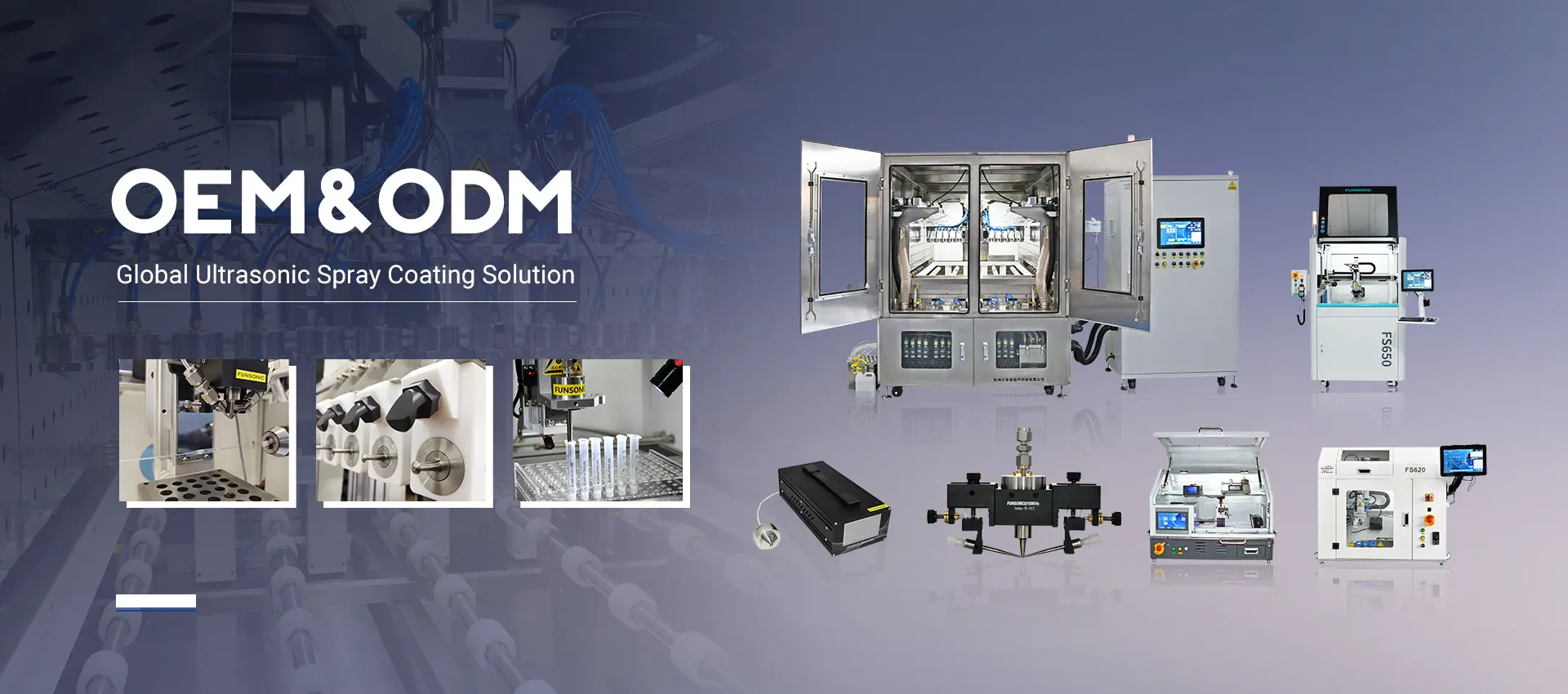

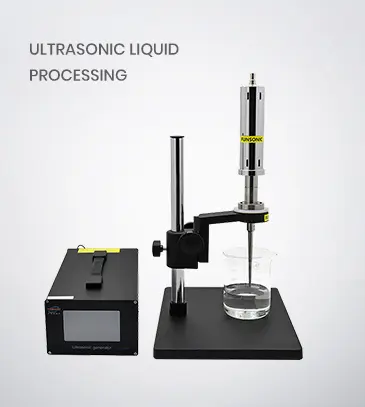

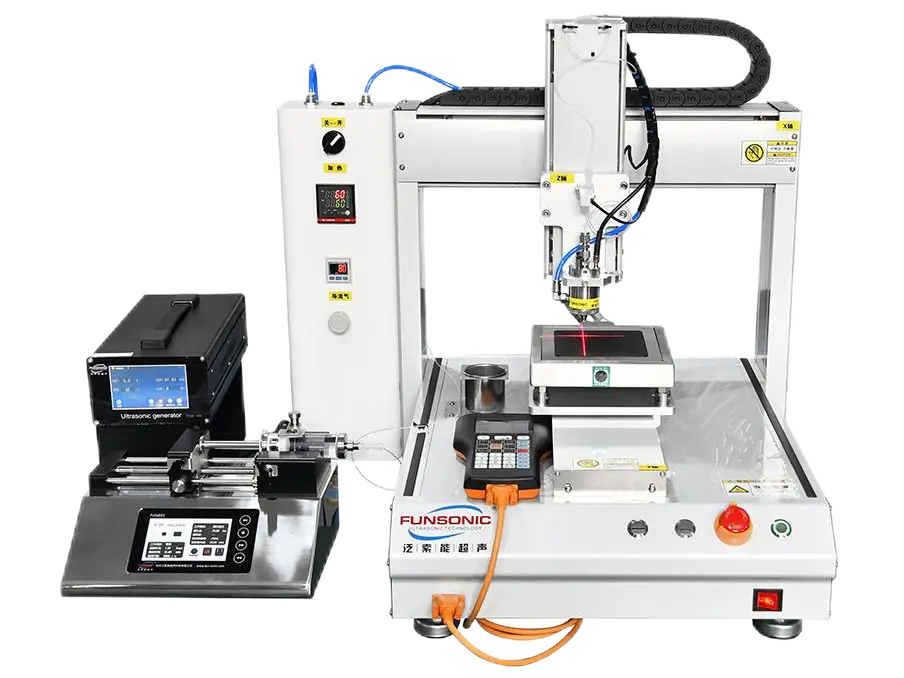

FUNSONIC was established in 2018 and is composed of several engineers with more than 10 years of practical experience in the field of high-power ultrasound. FUNSONIC focus on the development and manufacture of ultrasonic equipment, such as ultrasonic spray coating machine, ultrasonic spray nozzle, ultrasonic welding equipment, ultrasonic cutting equipment, ultrasonic liquid processing equipment, various kinds of ultrasonic core components.

-

solutionIt's important to know the type of ultrasonic you need for your project before ordering. But if you don’t, no worries! Our colleagues will help you! Good service is a good beginning of the order.

solutionIt's important to know the type of ultrasonic you need for your project before ordering. But if you don’t, no worries! Our colleagues will help you! Good service is a good beginning of the order. -

Production (1-45 days)Customers pay the deposit, we will arrange the production within 1 day. Our approval process is efficient and fast to maximize the time and cost savings for our customers.

Production (1-45 days)Customers pay the deposit, we will arrange the production within 1 day. Our approval process is efficient and fast to maximize the time and cost savings for our customers. -

Shipping (20-30 days)There are different shipping ways for options. Air shipping is fast but expensive, it only takes 7-10 days max. Sea shipping is the most economical shipping way, it takes 20-30 days.

Shipping (20-30 days)There are different shipping ways for options. Air shipping is fast but expensive, it only takes 7-10 days max. Sea shipping is the most economical shipping way, it takes 20-30 days. -

After ServiceOur team is available to assist you with day-to-day tasks such as machine installation, spare parts delivery, commissioning, and maintenance.The warranty is one year after delivery.

After ServiceOur team is available to assist you with day-to-day tasks such as machine installation, spare parts delivery, commissioning, and maintenance.The warranty is one year after delivery.

0102

0102030405

Solutions

Choose right equipment as per different applicaitons.

Customization

Provide customized services according to actual needs.

Test

Offer free ultrasonic equipment testing based on customer samples.

Installation

Service of installation at customer's place.

Mold Design

Provide free mold design service of FUNSONIC ultrasonic products.

Training

Customer training in operation and maintenance.

0102

01020304